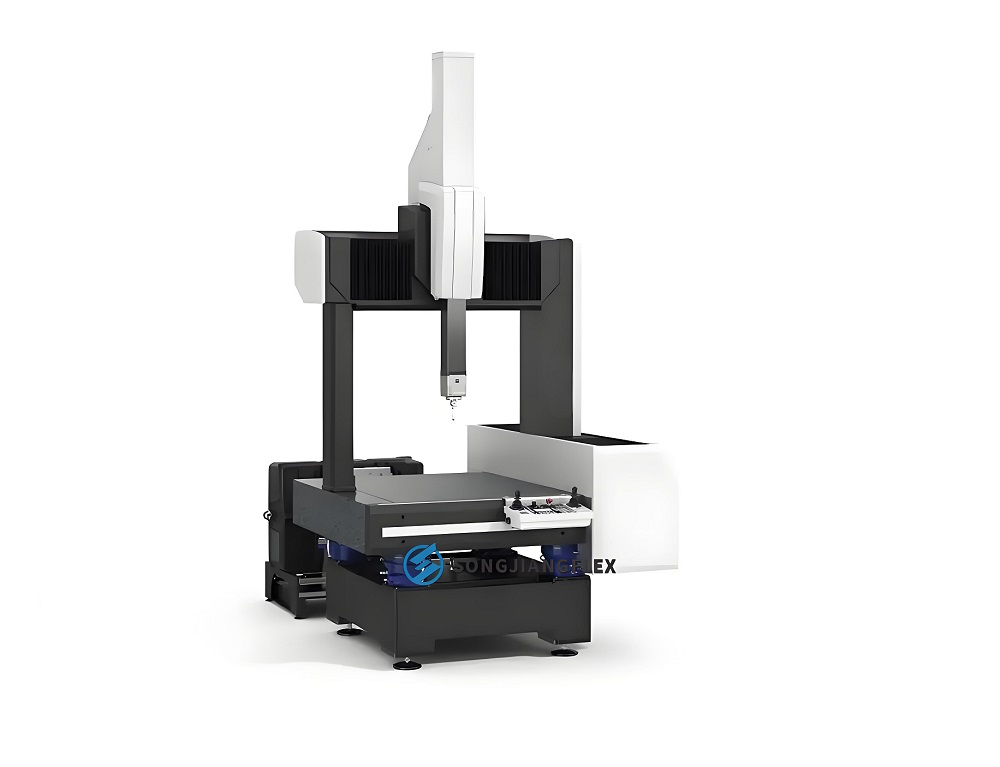

Why Should Gantry Coordinate Measuring Machines Use Air Vibration Isolators for Anti-Vibration Control?

Gantry CMMs are extremely sensitive to vibrations. Even minor floor vibrations can cause micrometer-level errors. Air vibration isolators ensure reliable anti-vibration solutions for precision measurement.

Air vibration isolators are essential for gantry CMM vibration control. By absorbing industrial floor vibration and reducing measurement errors, they provide high-performance anti-vibration solutions, enhancing metrology equipment stability and ensuring reliable CMM error reduction in industrial environments.

Let’s explore how air vibration isolators enhance gantry CMM stability and improve coordinate measuring machine accuracy.

1. Why Gantry CMMs Need Vibration Control

Gantry CMMs have large spans and perform high-precision measurements, making them extremely vulnerable to vibrations from internal and external sources.

Even minor industrial floor vibrations or environmental disturbances can reduce coordinate measuring machine accuracy.

Vibrations can shift the probe or gantry bridge, affecting high-precision CMM readings. Implementing gantry CMM vibration control ensures stable measurements and consistent CMM error reduction across applications.

2. What are the Main Sources of Vibration That Affect Gantry CMM Accuracy?

Vibrations impacting high-precision CMMs originate from multiple sources within industrial facilities.

Nearby machinery, forklifts, HVAC systems, and structural vibrations can all compromise precision measurement.

Internal machine movements and external industrial floor vibration are primary contributors. Understanding these sources helps design effective anti-vibration solutions for stable high-precision CMM performance.

3. How Do Air Vibration Isolators Improve Measurement Precision in Gantry CMMs

Air vibration isolators absorb floor-borne vibrations, providing a stable measurement platform for gantry CMMs.

They significantly reduce measurement errors and maintain coordinate measuring machine accuracy for high-precision CMMs.

Using a sealed air chamber, air vibration isolators enhance gantry CMM vibration control and enable consistent precision measurement in metrology equipment.

4. How Air Vibration Isolators Work

Air vibration isolators use an air-filled chamber as a flexible cushion to dampen vibrations.

Compared to rubber or mechanical isolators, they offer lower natural frequency and superior vibration damping system performance.

The air chamber compresses under vibrations, absorbing energy before reaching the high-precision CMM. Rubber air isolators provide effective CMM error reduction in industrial environments.

5. Differences Between Passive and Active Vibration Isolation

CMMs can use passive or active vibration isolation depending on environmental conditions.

Active vibration isolation adjusts dynamically, while passive systems rely on static damping characteristics.

Active vibration isolation is ideal for variable industrial floor vibration; passive works best in stable conditions. Both anti-vibration solutions protect precision measurement.

6. Rubber Air Isolators vs Traditional Mechanical Isolators

Rubber air isolators combine elasticity and damping efficiency for high-precision CMMs.

They outperform rigid mechanical isolators, especially in absorbing low-frequency industrial floor vibration.

Rubber air isolators offer longer-lasting isolation, compliance under varying loads, and better precision measurement, making them preferred for gantry CMM vibration damping systems.

7. Can Air Vibration Isolators Reduce Measurement Errors Caused by Floor Vibrations?

Floor-borne vibrations are a major source of coordinate measuring machine accuracy errors.

Air vibration isolators absorb these vibrations, significantly reducing measurement errors.

By decoupling the CMM from the floor, air vibration isolators mitigate industrial floor vibration, maintaining stable high-precision CMM operation.

8. How Does the Load Capacity Affect Isolator Choice?

The weight and distribution of a gantry CMM influence isolator performance and selection.

Properly matched air vibration isolators ensure optimal gantry CMM vibration control.

Load considerations determine isolator sizing and air chamber pressure. Air vibration isolators can be customized to support heavy or unevenly loaded CMMs.

9. Industry Standards for Vibration Control in CMMs

Standards maintain consistent measurement accuracy across facilities.

Compliance with ISO 10360, ISO 8570, and other regulations ensures reliable vibration damping system performance.

Air vibration isolators help meet industry standards, enhancing precision measurement and CMM error reduction.

10. Environmental Factors: Temperature and Humidity

Temperature and humidity influence air vibration isolator performance.

Variations can affect air stiffness and damping efficiency, impacting gantry CMM vibration control.

Stable environmental control ensures optimal precision measurement and reliable CMM error reduction.

11. Maintenance for Air Isolators

Regular maintenance preserves isolator performance and stability.

Check air pressure, seals, and leveling to maintain effective vibration damping system functionality.

Preventive maintenance, including leak inspections and pressure adjustments, ensures reliable operation of high-precision CMM.

12. Long-Term Cost Benefits

Investing in air vibration isolators provides long-term savings for gantry CMM operators.

Reduced measurement errors, equipment wear, and downtime result in high ROI for precision measurement operations.

Air vibration isolators reduce recalibrations and defects, extend metrology equipment lifespan, and deliver sustainable cost benefits.

Summary

Air vibration isolators offer superior gantry CMM vibration control, enhancing precision measurement, reducing errors, and ensuring long-term metrology equipment stability.