Why Are SHM Adjustable Spring Vibration Isolators Crucial for Generator Sets in Cloud Data Centers?

Generator vibrations can disrupt sensitive servers and building structures, risking downtime. SHM adjustable spring vibration isolators provide a precise solution.

SHM adjustable spring vibration isolators ensure effective generator vibration isolation, especially low-frequency vibration isolation, meeting data center vibration control requirements and supporting Tier III and Tier IV standards.

Let’s explore how SHM spring isolators tackle generator vibration challenges in cloud data centers.

1. What types of vibration do generator sets produce in cloud data centers, and why are they a risk?

Generator sets in cloud data centers produce a combination of low-frequency vibrations, mechanical shocks, and resonance. These vibrations can compromise server stability, damage structural components, and increase maintenance demands.

Generator vibration isolation is essential because these low-frequency and high-amplitude vibrations can propagate through floors, affecting both equipment and personnel safety, highlighting the importance of precise isolation systems.

Low-frequency vibration from diesel generators or large generator sets often spreads to the data center floor and sensitive server racks. Without proper isolation, this can lead to misaligned equipment, server downtime, and accelerated wear. An SHM adjustable spring vibration isolator absorbs these vibrations efficiently, providing a stable operational environment and supporting reliable Tier III and Tier IV data center performance.

2. Why is low-frequency vibration control critical for generator sets in cloud data centers?

Low-frequency vibrations are particularly harmful because standard rubber mounts often fail to dampen them. These persistent oscillations can affect sensitive IT equipment and building structures over time.

Effective low-frequency vibration isolation ensures the longevity of generators and prevents operational disruptions, making SHM adjustable spring vibration isolators an essential component for data center vibration control.

Low-frequency vibration isolation is crucial for maintaining server reliability. Generator vibration can resonate with building structures, amplifying the effect. By using SHM adjustable spring vibration isolators, engineers achieve precise control over low-frequency disturbances, reducing noise and preventing structural fatigue while optimizing diesel generator vibration control and data center performance.

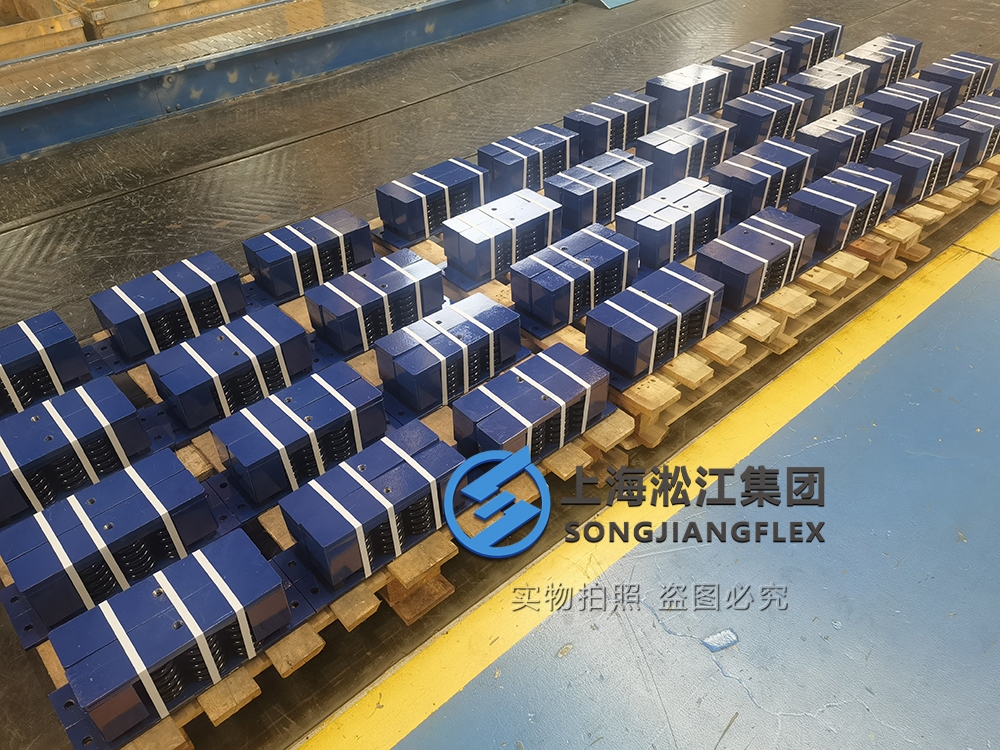

3. What is an SHM adjustable spring vibration isolator and how does it work?

An SHM adjustable spring vibration isolator combines high-quality springs with damping elements. Its adjustable load and height allow engineers to match generator weight and vibration characteristics precisely.

SHM adjustable spring vibration isolators provide reliable generator vibration isolation, low-frequency vibration isolation, and improved operational stability compared to conventional mounts.

The design of SHM spring isolators allows fine-tuning of stiffness and damping. Adjustable spring vibration isolators support generator leveling isolator functions, compensating for floor irregularities and structural variations. This adaptability ensures both diesel generator vibration control and compliance with Tier III and Tier IV data center standards.

4. How do SHM adjustable spring isolators outperform rubber mounts for generator sets?

Traditional rubber mounts can degrade over time and lack sufficient low-frequency damping. SHM adjustable spring vibration isolators provide superior long-term performance and consistency.

Compared to rubber mounts, SHM adjustable spring isolators ensure effective low-frequency vibration isolation, supporting reliable data center vibration control and generator longevity.

Rubber mounts may soften, creep, or fail under heavy generator loads, especially over extended use. SHM adjustable spring isolators maintain consistent damping and vibration isolation, outperforming rubber mounts in both efficiency and durability. Their precision supports vibration and noise control for generators while meeting high-tier data center requirements.

5. Why is height adjustability essential for generator leveling and vibration performance?

Proper generator leveling is critical to prevent uneven load distribution and vibration amplification. Adjustable spring isolators allow engineers to fine-tune generator position.

Height adjustability ensures optimized generator vibration isolation, improving diesel generator vibration control and overall data center operational stability.

Generator leveling isolator functionality allows compensating for floor settling or uneven surfaces. By adjusting the spring height, SHM adjustable spring vibration isolators maintain balanced loads, reduce structural stress, and optimize vibration control. This ensures Tier III and Tier IV data centers operate efficiently without server disruption.

6. How do SHM spring vibration isolators support high-reliability cloud data center operations?

Reliable operation in high-tier data centers requires consistent generator vibration isolation. SHM adjustable spring vibration isolators ensure minimal vibration transmission to sensitive equipment.

These isolators provide low-frequency vibration isolation, maintain generator leveling, and support data center vibration control, enhancing long-term reliability and uptime.

SHM spring vibration isolators reduce vibration and noise for generators, improving server stability and structural safety. Their durability and adjustability allow data centers to meet Tier III and Tier IV standards while minimizing maintenance, downtime, and operational disruptions, making them ideal for high-reliability cloud environments.

7. What factors should engineers consider when selecting SHM adjustable spring vibration isolators for generator sets?

Engineers must evaluate generator weight, operating frequency, installation conditions, environmental factors, and long-term maintenance when choosing isolators.

Selecting the right SHM adjustable spring vibration isolator ensures effective generator vibration isolation, low-frequency vibration isolation, and compliance with Tier III and Tier IV data center standards.

Key considerations include spring stiffness, damping capacity, height adjustability, and compatibility with diesel generator vibration control requirements. Engineers should also consider site-specific floor conditions and operational load variations. Correct selection optimizes data center vibration control, protects servers, and extends generator service life.

Summary

SHM adjustable spring vibration isolators provide precise, low-frequency vibration isolation, ensuring reliable, long-term generator performance in cloud data centers.