ZS-400-5 Self-sealing Air Spring

ZS-5 Series Self-sealing Air Spring for Punching Machine

Frequently Asked Questions

What is a self-sealing rubber air spring for punching machines?

The ZS Series Air Springs are high-performance vibration isolation and support components specifically designed to withstand the intense vibrations in punching machines and similar heavy-duty industrial equipment. These air springs consist of multiple layers of air bags (single-layer, double-layer, triple-layer, four-layer, and five-layer configurations), effectively isolating and absorbing vibrations to ensure smooth operation and reduce wear on the equipment. Here are the key features and applications of the ZS Series:

Key Features:

Multi-Layer Air Bag Design: The ZS series offers configurations with one to five layers of air bags, providing different levels of vibration isolation to meet the demands of various working loads.

Steel (Galvanized) Collar: A steel (galvanized) collar is placed between the layers of the air bags to prevent expansion, ensuring the stability and safety of the springs under high-pressure conditions.

Self-Sealing Function: The air bags in the ZS series are designed to self-seal without the need for external force, eliminating the risk of air leakage commonly seen with traditional rubber-based air springs and ensuring reliable, long-term performance.

High Load Capacity: ZS series air springs can support the heavy loads required in punching machines, including high-frequency and heavy-duty environments such as high-speed presses and hydraulic presses.

Durability and Corrosion Resistance: The materials used in the air bags are treated to be wear-resistant and corrosion-resistant, making them ideal for harsh environments like marine, chemical, or offshore industries.

How Does the ZS Series Self-sealing air springs Function?

The ZS Series Self-Sealing Air Springs function by utilizing a combination of air pressure and advanced design features to isolate and absorb vibrations, shocks, and impacts in heavy-duty machinery, such as presses, stamping machines, and other industrial equipment. Here’s how they work:

1. Air Bag Structure:

The ZS Series air springs are made up of multiple layers of air bags (typically ranging from one to five layers), which can provide varying degrees of vibration isolation based on the load and operational conditions. These air bags are filled with air or gas, and their design allows them to expand and contract under pressure.

2. Self-Sealing Mechanism:

One of the most unique features of the ZS Series air springs is their self-sealing capability. The air bags are designed in such a way that they can maintain their internal pressure and prevent air leakage without the need for external sealing force. This self-sealing function ensures that the air spring maintains its damping performance over time, even under extreme operational conditions.

This is achieved through the use of high-quality elastomeric materials and a precise construction process that guarantees a strong seal around the air bag. The system is fully airtight, minimizing the risk of pressure loss and ensuring consistent performance.

3. Vibration and Shock Absorption:

When the machinery operates, vibrations and shocks are transmitted through the equipment. The air bags in the ZS Series air springs compress and expand to absorb these mechanical forces. The air pressure inside the spring increases to cushion the impact, while the flexible layers of the air bags help to isolate the vibrations, preventing them from being transmitted to other parts of the system.

The multi-layer structure of the air spring enhances its ability to absorb different types of vibrations — from low-frequency, heavy shocks to high-frequency oscillations, making it versatile for various industrial applications.

4. Steel Collar Reinforcement:

In multi-layer configurations, the ZS Series air springs are equipped with a steel (galvanized) collar between the layers. This steel collar helps to prevent the air bags from expanding uncontrollably, providing structural support and enhancing the durability of the air spring. It also helps maintain the shape and stability of the spring under high loads, ensuring consistent performance even in heavy-duty applications.

5. High Load Capacity and Durability:

The combination of the self-sealing feature, multi-layer air bag structure, and steel collar reinforcement allows the ZS Series air springs to support high loads and operate effectively in challenging environments. The durable construction ensures they can withstand harsh conditions, such as exposure to chemicals, moisture, and extreme temperatures, making them ideal for use in a wide range of industries.

What are the applications of ZS Series Self-sealing Air Spring for Punching Machine?

Self-sealing air springs play a crucial role in various industrial equipment, especially in high-load and high-frequency vibration environments, such as presses, stamping machines, mechanical presses, pneumatic presses, hydraulic presses, high-speed mechanical presses, high-frequency presses, CNC presses, and more. Their unique design allows them to effectively absorb and isolate vibrations and shocks, reducing equipment wear, extending service life, and improving overall operational stability.

Applications of Self-Sealing Air Springs:

Pressing and Stamping Equipment:

- Mechanical presses, pneumatic presses, hydraulic presses: These machines typically experience high-frequency, high-load impacts. Self-sealing air springs absorb vibration and shock, preventing excessive wear, improving stability, and maintaining precision.

- High-speed mechanical presses, high-frequency presses: These machines generate intense vibrations during high-speed operations, which can significantly impact their performance. Self-sealing air springs effectively absorb high-frequency vibrations, reduce noise, and ensure smooth operation.

- CNC presses, conventional mechanical presses: For equipment requiring high precision, self-sealing air springs enhance system stability, reduce vibration-induced errors, and improve pressing accuracy and production efficiency.

- Manual presses, spiral presses, rack-and-pinion presses, link-type presses, cam presses: These machines endure substantial mechanical shocks. Self-sealing air springs support these loads while isolating vibrations, offering a more stable operating environment.

Papermaking Equipment and Production Lines:

- Papermaking equipment and production lines: Equipment in papermaking industries often operates continuously for extended periods, generating vibrations and shocks that could lead to mechanical failures and reduced efficiency. Self-sealing air springs reduce these vibrations, enhance equipment longevity, and minimize downtime due to maintenance.

- Paper processing machinery: In high-speed, high-load operations during paper processing, vibrations can negatively impact equipment accuracy and stability. Self-sealing air springs absorb these vibrations, improving production efficiency and product quality.

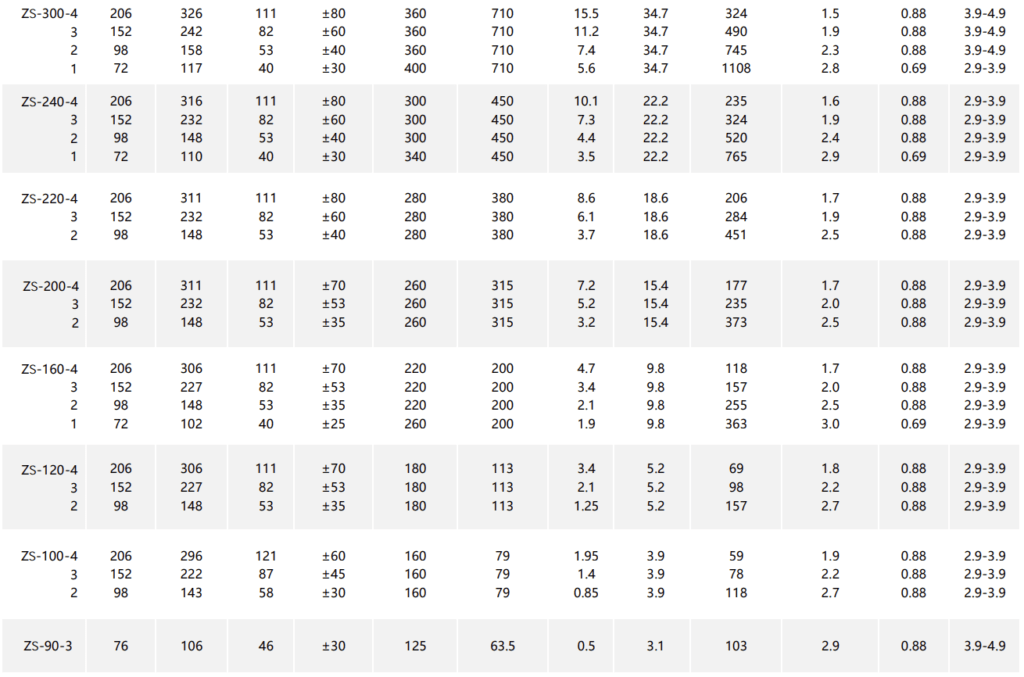

The ZS Series Self-Sealing Bellow-type Air Springs are named “bellow-type” due to their bellows-like (accordion) shape. Bellow-type air springs are generally divided into self-sealing and closed types. The rubber air bag ①, reinforced with fiber layers, is fitted with a low-carbon steel (galvanized) collar ② to prevent expansion. Under internal air pressure, the rubber air bag deforms, and to prevent air leakage, steel wire rings ③ and the top and bottom panels (galvanized) ④ make close contact. The top and bottom panels are available in both machined and stamped types, which can be selected based on the application (refer to tables 2 and 3). ⑤ is the threaded part for air piping, and ⑥ is the threaded hole for installation. Unlike the closed type, the self-sealing type has metal fittings ⑦ and ⑧ embedded in the rubber air bag at both ends, serving both as the air supply and for fixing purposes.

Do Not Exceed the Recommended Safe Extended Height: When installing or using an air spring, ensure that it is not extended beyond the recommended height. Exceeding this height could lead to excessive strain on the air spring, resulting in damage or reduced performance over time. Always follow the manufacturer’s guidelines regarding the safe extended height for proper operation.

Avoid Using Below the Minimum Compressed Height: To prolong the lifespan of the air spring, it is crucial not to operate it below its minimum compressed height. Operating below this threshold can cause the rubber bladder to become overstretched, leading to premature wear and potential failure. Ensure the air spring is within the correct compression range during use.

Do Not Use at a Pressure Exceeding 0.7 MPa: The air spring must be operated within the specified pressure limits to maintain optimal performance and safety. Exceeding a pressure of 0.7 MPa could lead to over-stretching of the air spring, compromising its structural integrity. Always check and regulate the air pressure according to the manufacturer’s recommendations.

Avoid Twisting the Air Spring: During installation and use, it is important to avoid twisting the air spring. A twisted air spring can lead to uneven distribution of air pressure, causing internal damage or even failure. Make sure the air spring is installed in a straight and aligned position to ensure proper function and durability.

- The air spring is typically available in stock.

- The air springs manufactured by Shanghai Songjiang meet national standards and come with a one-year warranty. Any quality issues can be exchanged within this period.

- There is no purchase quantity limit. Small orders are generally shipped via international couriers such as DHL, FEDEX, UPS, TNT, etc., ensuring fast delivery, usually within 3-7 business days.

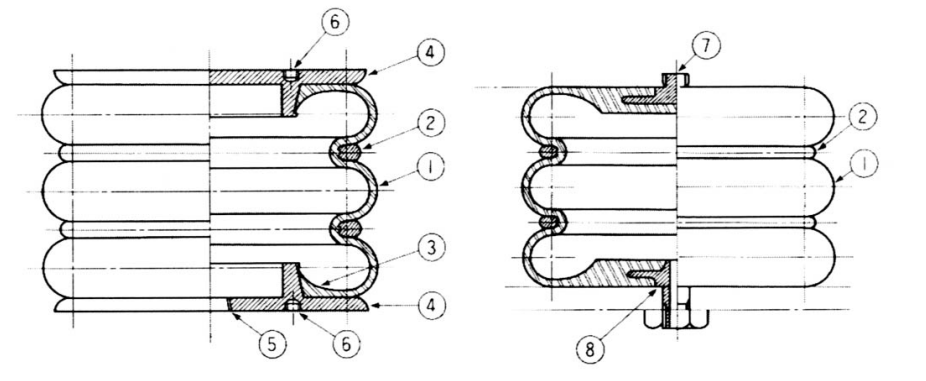

ZS-400-5 Self-sealing Air Spring/Match Yokohama model: ZS-400-5

Model:ZS-400-5

Design Height:276mm

Max Height: 435mm

Min Height: 156mm

Commonly Used Maximum:±113mm

Compressed Maximum Outer Diameter:460mm

Maximum operating internal pressure: 0.69M

Failure internal pressure: 3.9-4.9 Mpa

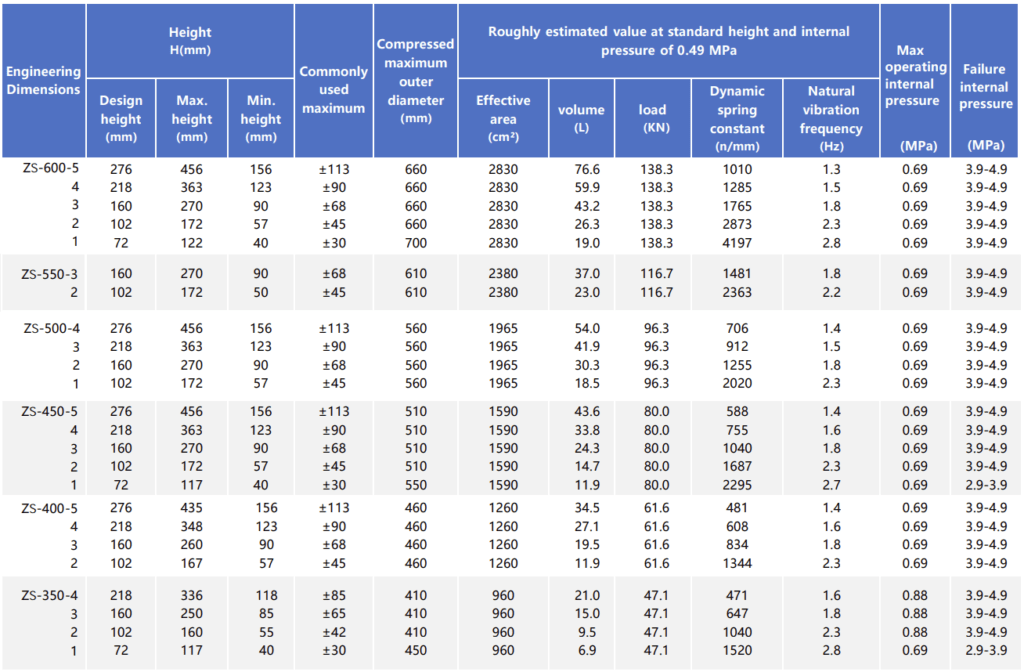

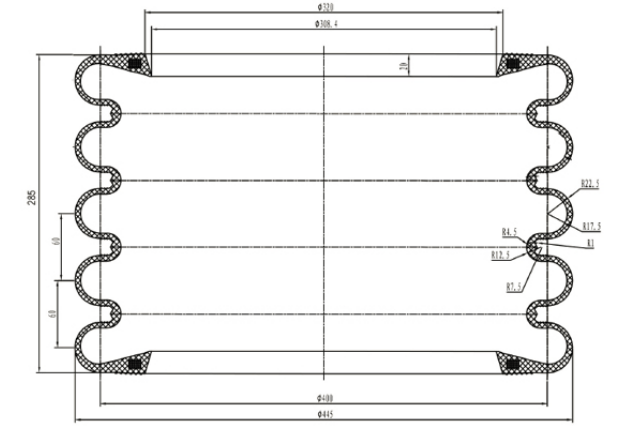

Model List for ZS Series Self-Sealing Air Bags for Punching Machines: