STR Rubber vibration isolator

STR Rubber vibration isolator

Frequently Asked Questions

What systems are STR Rubber vibration isolator used in?

STR Rubber Vibration Isolators are used in various systems to reduce vibration and noise. Common applications include:

- HVAC Systems: For isolating air handling units, compressors, and ductwork.

- Industrial Machinery: Used to protect sensitive equipment from vibrations and improve operational stability.

- Transportation: Installed in vehicles, trains, and ships to minimize vibration and noise.

- Power Generation: Applied in generators, turbines, and other heavy machinery to reduce operational vibrations.

- Building Foundations: To isolate vibrations from mechanical equipment like pumps and compressors from surrounding structures.

These isolators are versatile, providing effective vibration control in diverse industries.

How does the STR Rubber vibration isolator work?

The STR Rubber Vibration Isolator works by absorbing and dissipating the energy generated from vibrations, thereby preventing these vibrations from being transmitted to the surrounding structure or machinery. Here’s how it works:

Elastic Compression: When equipment generates vibrations, the rubber isolator compresses and deforms, absorbing the vibrational energy. The rubber’s elasticity helps it return to its original shape, reducing the intensity of vibrations.

Damping Effect: The rubber material provides damping, meaning it converts the vibrational energy into heat, which is then dissipated, effectively reducing the transmission of noise and vibrations.

Isolation: By placing the isolator between the equipment and its mounting surface, it isolates the system from external vibrations, ensuring that vibrations do not propagate to other components or structures.

This mechanism makes STR Rubber Vibration Isolators highly effective at reducing noise, wear, and damage caused by vibrations in industrial, HVAC, and transportation systems.

What are the product advantages of STR Rubber vibration isolator ?

The STR Rubber Vibration Isolator offers several advantages that make it a preferred choice for vibration control in various applications:

Effective Vibration Isolation: STR rubber isolators efficiently absorb and reduce vibrations, preventing them from transferring to nearby structures or equipment, ensuring smoother operation.

Durability: Made from high-quality rubber materials, these isolators offer long-lasting performance, even under heavy loads and in harsh environments, with minimal wear and tear.

Noise Reduction: The rubber material helps to dampen both vibration and noise, leading to quieter operation in industrial machinery, HVAC systems, and transportation.

Cost-Effective: With their long lifespan and low maintenance needs, STR rubber isolators offer a cost-efficient solution for vibration control, reducing the need for frequent replacements.

Versatility: They are suitable for a wide range of applications, including HVAC systems, industrial machinery, power generation, and transportation, providing reliable vibration isolation across diverse industries.

STR Rubber Vibration Isolators are designed to provide effective vibration isolation across various systems. Their design features focus on durability, performance, and versatility:

Material Composition:

- Made from high-quality natural and synthetic rubber blends, designed for superior elasticity, resistance to wear, and environmental factors like heat, humidity, and UV exposure.

Shape and Structure:

- Available in different shapes, including cylindrical, conical, and square, to fit a variety of installation requirements.

- Some models feature multiple layers or configurations, combining rubber with steel or other reinforcements for added strength and performance.

Load Distribution:

- The design ensures even load distribution, preventing stress concentrations that could lead to premature wear or failure.

- Each isolator is tailored to handle specific load capacities, making them adaptable to different machinery and equipment types.

Compression and Damping:

- The isolators are designed to compress under load, absorbing vibrational energy and converting it into heat, which is dissipated over time. This reduces noise and vibration transmission to surrounding structures.

Mounting Options:

- Equipped with various mounting options such as threaded studs, flanges, or bolt holes for easy integration into different systems, ensuring secure attachment to both equipment and foundations.

Customization:

- STR rubber isolators can be customized for specific applications, including variations in size, stiffness, and environmental resistance, providing tailored vibration isolation solutions.

When installing and using STR Rubber Vibration Isolators, it’s important to follow these precautions to ensure optimal performance and longevity:

1. Proper Alignment

- Ensure that the isolators are properly aligned during installation to avoid uneven load distribution. Misalignment can lead to premature wear and reduced isolation efficiency.

2. Verify Load Capacity

- Make sure that the isolator’s load capacity matches the equipment’s weight. Overloading can cause the isolator to deform or fail. Use the correct number of isolators to evenly distribute the load.

3. Surface Preparation

- Clean and smooth the surfaces where the isolator will be mounted. Rough or uneven surfaces can lead to improper contact, affecting the performance of the isolator.

4. Avoid Over-tightening

- When installing the isolator, do not over-tighten the bolts or fasteners, as this can compress the rubber excessively and reduce its vibration-absorbing capabilities.

5. Environmental Compatibility

- Ensure that the STR Rubber Isolator is suitable for the environmental conditions it will be exposed to, such as high temperatures, moisture, or chemicals. Select the appropriate material for the application.

6. Regular Inspections

- Periodically inspect the isolators for signs of wear, cracks, or deformation. Replace any damaged isolators immediately to maintain effective vibration isolation.

7. Avoid Lateral Forces

- Ensure the isolators are not exposed to excessive lateral or horizontal forces, as they are designed to absorb vertical vibrations. Lateral movement can cause instability or damage to the isolator.

8. Optimal Deflection

- Make sure the isolators are within their optimal deflection range during installation. Over-compressing or under-compressing the isolator can reduce its effectiveness.

9. Follow Manufacturer Guidelines

- Always refer to the manufacturer’s installation instructions for specific guidelines and parameters. Using the isolator outside of these recommendations can lead to failure or reduced performance.

- STR Rubber vibration isolator are typically available in stock.

- STR Rubber vibration isolator manufactured by Shanghai Songjiang meet national standards and come with a one-year warranty. Any quality issues can be exchanged within this period.

- There is no purchase quantity limit. Small orders are generally shipped via international couriers such as DHL, FEDEX, UPS, TNT, etc., ensuring fast delivery, usually within 3-7 business days.

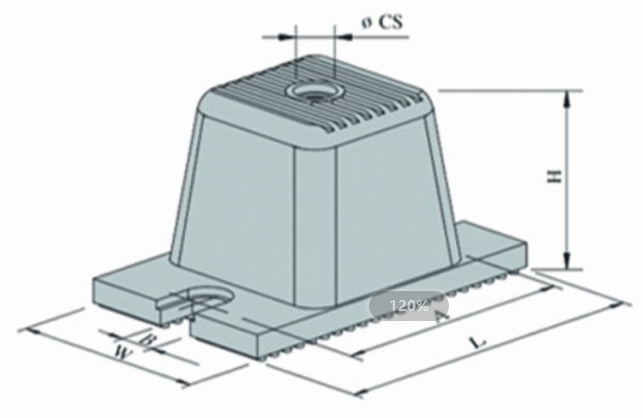

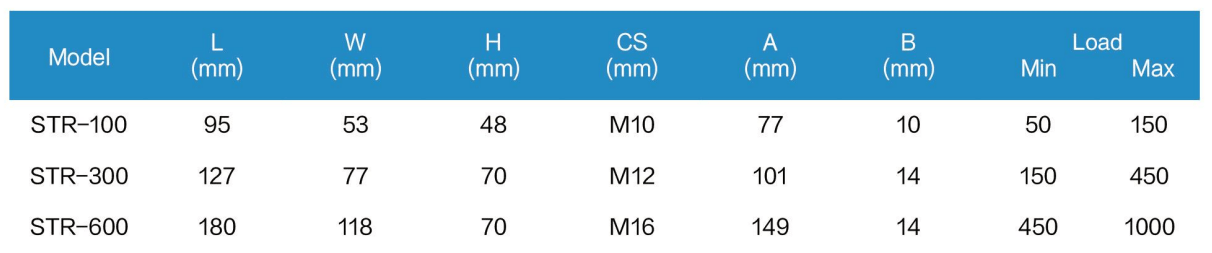

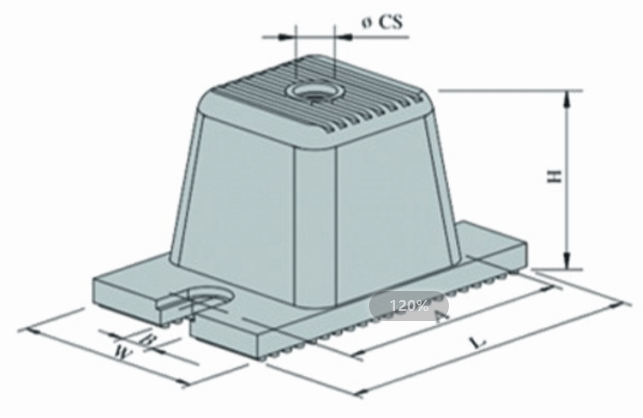

STR Rubber vibration isolator Data Parameters: