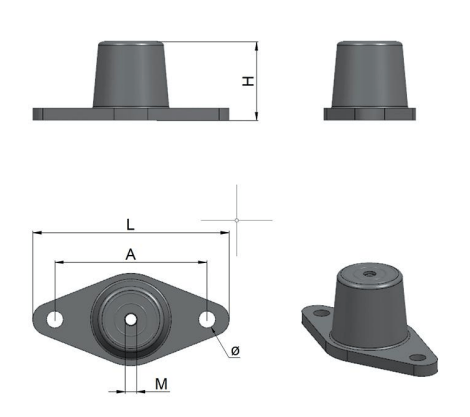

RM Elastomeric Vibration Isolators

RM Elastomeric Vibration Isolators

Frequently Asked Questions

What systems are RM Elastomeric Vibration Isolators used in?

RM Elastomeric Vibration Isolators are commonly used in the following systems:

HVAC Systems: To isolate vibrations from fans, pumps, and air handling units, ensuring quiet operation and reducing structural wear.

Industrial Machinery: In manufacturing facilities to minimize vibration and noise generated by heavy equipment, improving both performance and operator comfort.

Pumps and Compressors: To absorb vibrations from pumps, compressors, and other rotating machinery, reducing noise and preventing damage to surrounding structures.

Power Generation Systems: Used in turbines, generators, and other critical equipment to minimize vibrations and enhance operational efficiency.

Transportation Systems: In trains, buses, and other vehicles to isolate road or track vibrations, improving comfort and reducing wear on the vehicle structure.

Elevator and Escalator Systems: To reduce the transmission of vibrations, improving the smoothness of operation and longevity of components.

Building Foundations: Used in construction to isolate vibrations from machinery, reducing structural damage and noise pollution.

How does the RM Elastomeric Vibration Isolators work?

RM Elastomeric Vibration Isolators work by using the inherent properties of elastomeric materials (such as rubber or synthetic polymers) to absorb and dampen vibrations. Here’s how they function:

Vibration Absorption: The elastomeric material within the isolator compresses and stretches in response to vibrations, absorbing the energy and preventing it from being transmitted to surrounding structures. This reduces the impact of the vibrations on equipment and nearby systems.

Damping Effect: As the elastomer is deformed by the vibrations, it dissipates the kinetic energy through internal friction, which helps to dampen high-frequency oscillations and prevent the vibrations from spreading.

Elastic Recovery: Once the external vibration force is removed, the elastomeric material returns to its original shape, ensuring that the isolator is ready for the next cycle of vibration without losing its effectiveness.

Load Distribution: The design of RD Elastomeric Vibration Isolators ensures that vibrations are distributed evenly across the isolator surface. This helps maintain stability and prevents localized over-compression that could lead to premature wear.

What are the product advantages of RM Elastomeric Vibration Isolators ?

RM Elastomeric Vibration Isolators offer several distinct advantages, making them an ideal solution for a wide range of industrial applications. Here are the key benefits:

Effective Vibration Dampening: The elastomeric material absorbs and dissipates vibration energy, effectively isolating equipment from harmful vibrations, reducing noise, and preventing the transmission of vibrations to nearby structures.

Durability and Longevity: Made from high-quality elastomers, these isolators are designed to withstand long-term wear and environmental stress, ensuring reliable performance over time, even in harsh conditions.

Versatility: RD Elastomeric Isolators are suitable for a broad range of applications, including HVAC systems, industrial machinery, and equipment in power generation. They can be customized to suit specific vibration frequencies and load capacities.

Low Maintenance: With their robust construction and long-lasting materials, RD Elastomeric Vibration Isolators require minimal maintenance, reducing downtime and lowering long-term operating costs.

Compact Design: These isolators offer effective vibration isolation without taking up excessive space, making them ideal for installations with limited room or where compact solutions are necessary.

Cost-Effective: RD Elastomeric Isolators provide a cost-efficient way to protect machinery, reduce operational noise, and extend the lifespan of both equipment and structures, leading to long-term savings on repairs and replacements.

Corrosion and Weather Resistance: They are resistant to a variety of environmental factors such as moisture, temperature extremes, and chemicals, ensuring that they continue to perform reliably in different working conditions.

RM Elastomeric Vibration Isolators are designed to offer effective vibration isolation with the following key advantages:

High-Quality Elastomer Materials: Made from a blend of natural and synthetic rubber, RM Isolators provide excellent elasticity, durability, and resistance to aging, extreme temperatures, UV exposure, and environmental factors like oils and chemicals.

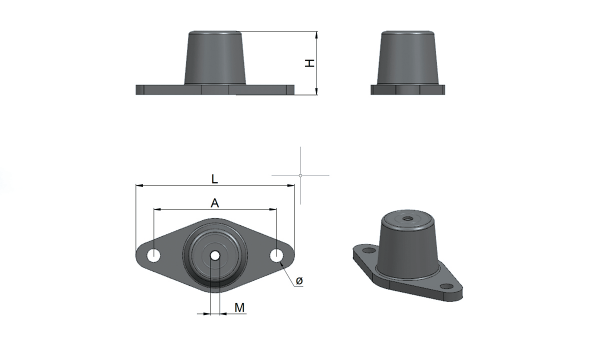

Modular Design: Available in various shapes and sizes (circular, square, cylindrical), RM Isolators can be customized to meet specific load capacities and vibration frequency ranges, making them suitable for a wide range of applications.

Compression and Shear Resistance: The elastomeric material effectively absorbs compressive forces and resists shear forces, ensuring long-term stability and minimal deformation under load. This guarantees reliable performance even in heavy-duty environments.

Easy Installation: The compact design and pre-designed mounting features (such as threaded bolts, flanges, or studs) ensure quick and easy installation, making RM Isolators ideal for applications where space is limited or where easy integration with existing systems is necessary.

Durability and Low Maintenance: RM Elastomeric Isolators are resistant to high temperatures, humidity, and chemical exposure, requiring minimal maintenance over their lifetime. This reduces downtime and extends the lifespan of both the isolator and the equipment it protects.

RM Elastomeric Vibration Isolators provide efficient vibration isolation, enhanced durability, and versatility, making them an ideal solution for a wide range of industries, from industrial machinery to HVAC systems and beyond.

1. Correct Installation Alignment

- Ensure proper alignment during installation to avoid uneven load distribution. Follow the manufacturer’s guidelines for positioning. Misalignment can reduce isolation efficiency and cause damage.

2. Load Capacity and Distribution

- Confirm that the isolator’s load capacity matches the equipment’s weight. Overloading can lead to deformation or failure. Use the right number of isolators for even load distribution.

3. Surface Preparation

- Clean and smooth the mounting surfaces to avoid uneven pressure on the isolator. Ensure surfaces are level and stable for optimal performance. Irregularities can compromise vibration isolation.

4. Avoid Over-tightening

- Don’t over-tighten bolts, as excessive compression reduces isolation efficiency. Tighten only enough to secure the isolator without over-compressing it. Proper tension is key to performance.

5. Environmental Considerations

- Select isolators that match the environmental conditions (e.g., temperature, humidity, chemicals). Environmental factors can degrade elastomers over time. Choose materials resistant to specific conditions.

6. Regular Inspections

- Periodically check for wear, cracks, or deformation. Replace damaged isolators promptly to maintain vibration isolation. Ensure mounting bolts are secure.

7. Avoid Over-compression

- Avoid compressing isolators beyond their specified range. Over-compression can cause permanent damage. Ensure optimal deflection for effective vibration isolation.

8. Temperature Considerations

- Use isolators within their recommended temperature range. Excessive heat or cold can alter material properties. Ensure material suitability for extreme temperature conditions.

9. Avoid Lateral Movement

- Prevent excessive lateral or horizontal movement, which can cause instability. Isolators are designed for vertical vibration absorption. Lateral forces can damage the isolator and the system.

10. Consult Manufacturer Specifications

- Always follow the manufacturer’s installation and performance guidelines. Using isolators outside their recommended limits can lead to failure. Consult the manufacturer or engineer if unsure.

- RM Elastomeric Vibration Isolators are typically available in stock.

- RM Elastomeric Vibration Isolators manufactured by Shanghai Songjiang meet national standards and come with a one-year warranty. Any quality issues can be exchanged within this period.

- There is no purchase quantity limit. Small orders are generally shipped via international couriers such as DHL, FEDEX, UPS, TNT, etc., ensuring fast delivery, usually within 3-7 business days.

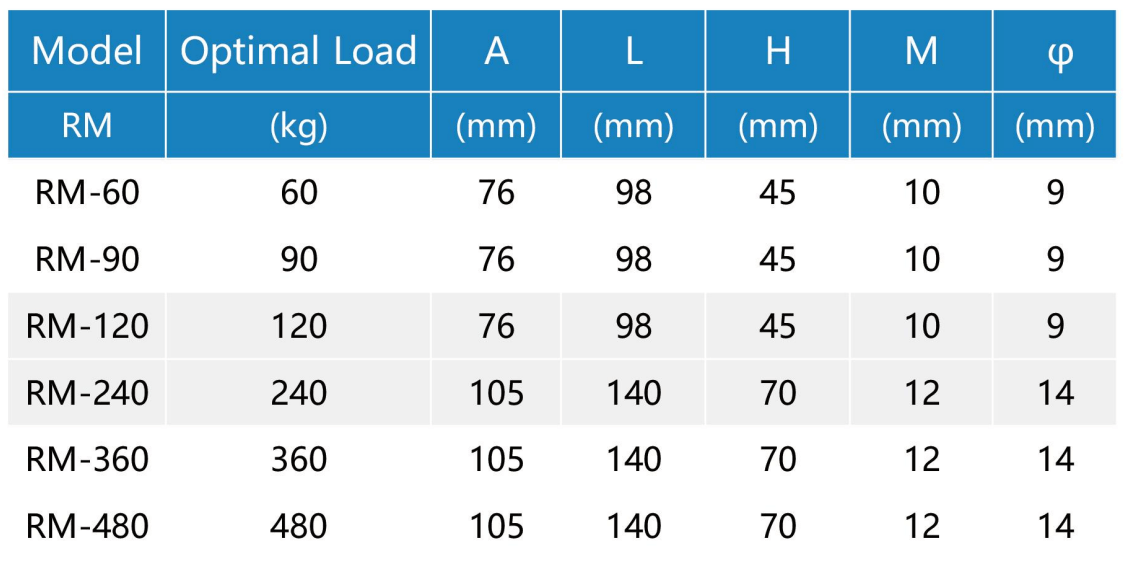

RM Elastomeric Vibration Isolators Data Parameters: