BE Rubber Vibration lsolator

BE Rubber Vibration lsolator

Frequently Asked Questions

What systems are BE Rubber Vibration Isolator used in?

The BE Rubber Vibration Isolator is commonly used in the following systems:

- HVAC systems – To reduce vibrations from air conditioning and ventilation equipment.

- Transformer systems – To isolate vibrations in electrical transformers, ensuring stable operation.

- Railway systems – To minimize vibrations in railway tracks and train equipment.

- Industrial machinery – To reduce vibrations in various types of industrial machines and equipment.

- Power plants – In systems such as generators and turbines to absorb vibrations.

- Building systems – In structural applications to dampen vibrations from mechanical systems.

These isolators help to improve the performance and longevity of the equipment by reducing wear and tear caused by vibrations.

How does the BE Rubber Vibration Isolator work?

The BE Rubber Vibration Isolator works by absorbing and isolating vibrations that are generated from various sources, such as machinery or mechanical systems. Here’s how it functions:

Vibration Absorption: The rubber material in the isolator acts as a shock absorber, cushioning the impact from vibrations. It deforms slightly under load, which helps to dissipate the energy from vibrations and prevent it from transferring to the connected structure.

Flexibility: The rubber provides flexibility and elasticity, which allows the isolator to effectively absorb different frequencies and amplitudes of vibrations. This is particularly useful in systems that experience dynamic forces or changing loads.

Damping Effect: The rubber material offers damping properties, which reduce the intensity of vibrations. This results in a quieter and more stable operation for the equipment.

Separation of Vibration Sources: The isolator physically separates the vibrating equipment from the surrounding structure, such as a building or machine frame, preventing the transfer of vibrations to these components.

Long-Term Durability: The high-quality rubber ensures long-term performance, maintaining its ability to isolate vibrations over an extended period, even under harsh operating conditions.

Overall, the BE Rubber Vibration Isolator helps to reduce noise, wear and tear, and improve the operational efficiency and longevity of various mechanical systems.

What are the product advantages of BE Rubber Vibration Isolator?

The BE Rubber Vibration Isolator offers several advantages that make it an effective solution for vibration and noise control:

Excellent Vibration Isolation: The high-quality rubber material effectively absorbs and isolates vibrations, preventing them from transferring to surrounding structures, which helps maintain a quieter and more stable environment.

Durability: Built to last, the isolator is made from durable, high-strength rubber that can withstand harsh operating conditions, ensuring long-term performance and reduced need for replacements.

Improved Equipment Longevity: By reducing vibration-induced wear and tear, the isolator helps extend the life of machinery, equipment, and structures.

Cost-Effective: It offers a low-maintenance solution that helps reduce operational costs by preventing damage to equipment and reducing noise-related issues.

Versatile Applications: Suitable for use in a wide range of systems, including HVAC systems, transformers, railway equipment, and industrial machinery, providing a flexible solution for different industries.

Easy Installation: The isolator is designed for simple installation, making it quick and cost-effective to integrate into new or existing systems.

These advantages make the BE Rubber Vibration Isolator an effective and reliable choice for vibration and noise control in various industrial and commercial applications.

The BE (Bilateral Elastic) Rubber Vibration Isolators are designed to reduce vibration transmission in various industries, especially for HVAC, machinery, and electrical equipment. These isolators absorb and dampen mechanical vibrations, ensuring smooth operation and extending the lifespan of both equipment and structures.

Key design features of BE Rubber Vibration Isolators include:

Bilateral Elastic Rubber Structure:

- The isolator uses rubber with elastic properties on both sides, allowing it to absorb vibrations from two directions, making it more effective for isolating vibrations from multiple sources.

Material Composition:

- The rubber is typically a blend of natural and synthetic elastomers, designed for high elasticity, durability, and resistance to environmental factors such as temperature, ozone, and aging.

Internal Steel Reinforcement:

- Steel reinforcements (e.g., plates or mesh) within the rubber enhance strength, reduce compression set, and improve load-bearing capacity, ensuring long-term performance.

Shape and Size Variability:

- Available in different shapes (cylindrical, spherical, rectangular) and sizes to meet specific load requirements and installation constraints.

Load Capacity and Stiffness:

- Designed with specific load requirements in mind, the rubber’s composition and geometry provide the right stiffness and damping properties to effectively reduce vibrations.

Vibration Damping:

- These isolators absorb high-frequency vibrations from machinery or equipment, reducing energy transmission and resulting in quieter operation and less wear on surrounding structures.

Installation Features:

- Easy to install with features such as threaded bolts, flanges, or mounting plates for secure attachment to both equipment and the foundation.

Customization:

- Customizable based on industry needs, ensuring the isolators meet the specific vibration frequencies, load capacities, and environmental factors of the application.

1. Proper Installation Alignment

- Ensure the isolators are aligned correctly during installation. Misalignment can reduce their effectiveness and lead to uneven distribution of load, causing premature wear or failure.

- Check that the isolator is installed in the intended direction to avoid improper functioning.

2. Load Capacity Consideration

- Verify that the isolator’s load capacity matches the equipment’s weight and expected operating conditions. Overloading can cause excessive compression or failure of the isolator.

- Use the correct number of isolators to distribute the load evenly.

3. Surface Preparation

- Make sure that the mounting surfaces (both on the equipment and the foundation) are clean, smooth, and free of any debris or irregularities. Rough or contaminated surfaces can affect the isolator’s performance and lead to premature wear.

4. Avoid Over-tightening

- When installing the isolators, do not over-tighten bolts or fasteners, as this can lead to deformation of the rubber and reduce its ability to absorb vibrations effectively.

- Tighten bolts just enough to secure the isolator in place without compressing the rubber excessively.

5. Environmental Factors

- Ensure that the isolators are suitable for the environmental conditions they will be exposed to. This includes factors such as temperature extremes, humidity, exposure to chemicals, or UV light, as these can degrade rubber over time.

- Use isolators with appropriate material properties for the specific environment (e.g., oil-resistant rubber for industrial applications).

6. Avoid Over-compression

- Ensure the isolator is not compressed beyond its recommended range during installation. Over-compressing can cause permanent deformation, reducing its effectiveness.

- Check that the isolator is functioning within its design parameters, particularly for high-load or high-frequency applications.

7. Regular Inspections

- Periodically inspect the isolators for signs of wear, cracks, or deformation, especially in heavy-duty applications. Damaged isolators should be replaced immediately to maintain vibration isolation performance.

- Also, check the mounting bolts and other installation components to ensure they remain secure.

8. Temperature Considerations

- BE Rubber Vibration Isolators perform best within a specific temperature range. If they are used in extreme temperatures (either too hot or too cold), their performance may degrade, and their lifespan may shorten. Ensure the chosen isolator can withstand the temperature conditions of the application.

9. Avoid Excessive Movement

- Ensure that the isolators are not subjected to excessive lateral or horizontal movement, as this can lead to instability or damage over time. The isolators should only be absorbing vertical vibrations.

10. Compatibility with Adjacent Systems

- Make sure that the isolator is compatible with the surrounding systems (such as piping, machinery, or structural components). Conflicting materials or installation designs can affect the overall performance of both the isolator and the system it supports.

11. Professional Consultation

- For complex or high-stakes applications (e.g., nuclear, heavy industrial machinery), it’s advisable to consult with professionals or engineers to ensure the correct choice and installation of vibration isolators.

BE Rubber Vibration lsolator are typically available in stock.

BE Rubber Vibration lsolator manufactured by Shanghai Songjiang meet national standards and come with a one-year warranty. Any quality issues can be exchanged within this period.

- There is no purchase quantity limit. Small orders are generally shipped via international couriers such as DHL, FEDEX, UPS, TNT, etc., ensuring fast delivery, usually within 3-7 business days.

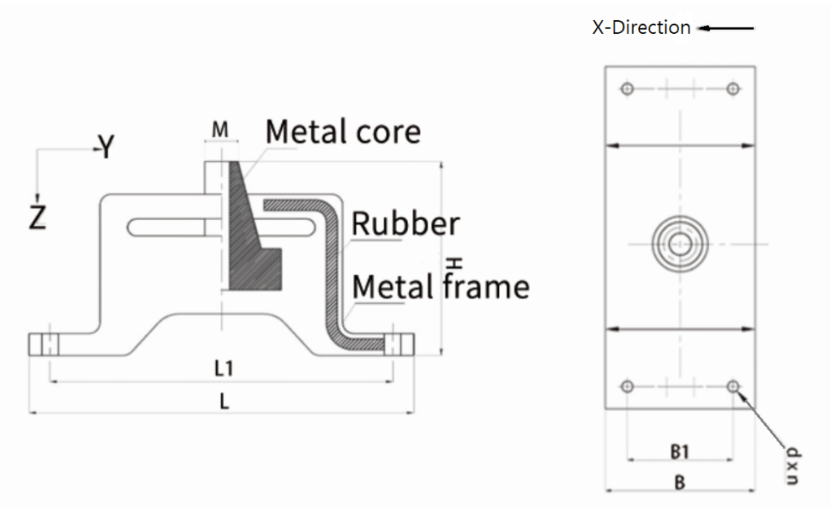

BE Rubber Vibration lsolator Data Parameters: