GF Series Paper Machine Airbag

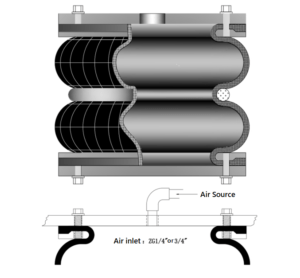

The GF Type Rubber Air Spring, also known as the fixed rubber air spring, is one of the most versatile types. It features wide upper and lower edges, allowing users to punch holes for installation. The air spring can then be fitted with matching flanges and end plates according to the user’s specific requirements, making it compatible with various machinery. While the fixed type is primarily used in papermaking machinery, it can also be selected for other machines based on specific application needs.

GF Series Paper Machine Airbag

Frequently Asked Questions

What are the key features of the GF Type Rubber Air Spring?

- Wide edges: The upper and lower edges are designed to allow users to easily punch holes for installation.

- Customizable: Users can install flanges and end plates according to their specific requirements.

- High versatility: It is compatible with various types of machinery.

- Durable: Made of high-quality rubber, ensuring long-term performance even in demanding environments.

How Does the GF Type Rubber Air Spring Function?

The GF Type Rubber Air Spring functions by utilizing the combined properties of rubber elasticity and compressed air to provide vibration damping and support for machinery. Here’s a breakdown of how it works:

Elasticity of Rubber:

The rubber material of the air spring is designed to be flexible and resilient. When the air spring is compressed or subjected to external forces (like vibrations or shocks), the rubber deforms to absorb the energy and reduce the transmission of vibrations to the surrounding structure. The rubber’s elasticity helps to maintain the shape of the air spring while providing a cushioning effect.Compressed Air:

The air inside the rubber air spring acts as a dynamic damping medium. The pressure of the air can be adjusted, which allows the air spring to vary its stiffness. By adjusting the air pressure, the damping characteristics of the air spring can be fine-tuned to match the specific requirements of the machinery or equipment it is supporting.Vibration Damping:

The GF Type Rubber Air Spring is particularly effective at absorbing low to medium frequency vibrations. As external forces (such as vibrations from machinery or equipment) impact the air spring, the rubber compresses and the internal air pressure absorbs and dissipates the energy. This reduces the amount of vibration transmitted to the rest of the system, protecting both the machinery and the operators.Support and Load Distribution:

In addition to damping vibrations, the air spring also provides support by evenly distributing the load placed on it. The rubber and air work together to support the weight of the machinery, ensuring stable operation while reducing the risk of mechanical wear and tear.Customization:

The performance of the GF Type Rubber Air Spring can be easily customized by adjusting the internal air pressure. This flexibility allows the air spring to be used in a wide range of applications, from heavy-duty machinery to sensitive equipment that requires fine-tuned vibration control.

What are the applications GF Series Paper Machine Airbag ?

The GF Series Paper Machine Airbag is specifically designed to meet the demanding needs of the papermaking industry. Its primary function is to provide vibration damping, load support, and cushioning to various components of paper machines. However, it can also be used in other industrial machinery that requires similar functions. Below are the main applications of the GF Series Paper Machine Airbag:

1. Papermaking Machinery

The GF Series Paper Machine Airbag is most commonly used in papermaking machines for several critical functions:

- Vibration Damping: It absorbs and reduces the vibrations caused by the fast-moving parts of the paper machine, such as the wet end and drying sections. This helps to improve the stability and smoothness of the paper production process, preventing defects in the paper quality.

- Load Support: It provides support to the weight of various machine components, such as the press section and drying rollers, ensuring stable operation and preventing mechanical wear.

- Cushioning: It acts as a cushion between the machine’s mechanical parts, reducing the impact of mechanical shocks and preventing damage to sensitive components.

2. Printing Presses

The GF Series Paper Machine Airbag can also be used in printing presses, where it helps to:

- Reduce Vibrations: It minimizes vibrations in the printing press, ensuring high-quality printing results and maintaining the accuracy of the printing process.

- Stabilize the Press Rollers: It provides stability to the press rollers, improving the uniformity and quality of printed material.

3. Pulp and Paper Industry Equipment

In the broader pulp and paper industry, the GF Series airbag can be used in:

- Conveyor Systems: To absorb the vibrations generated by conveyor belts carrying heavy paper rolls or pulp. This helps to prevent material damage and equipment wear.

- Drying Cylinders: Used in drying sections to stabilize the air pressure and improve the consistency of drying, reducing the risk of paper distortion.

4. Packaging Machinery

The GF Series Paper Machine Airbag can also find applications in the packaging industry, where it is used in machinery for:

- Vibration Control: In packaging machines that involve high-speed operations, the airbag helps to control vibrations, improving the precision and efficiency of the packaging process.

- Shock Absorption: It helps to protect delicate packaging materials from damage during transport or packaging.

Do Not Exceed the Recommended Safe Extended Height: When installing or using an air spring, ensure that it is not extended beyond the recommended height. Exceeding this height could lead to excessive strain on the air spring, resulting in damage or reduced performance over time. Always follow the manufacturer’s guidelines regarding the safe extended height for proper operation.

Avoid Using Below the Minimum Compressed Height: To prolong the lifespan of the air spring, it is crucial not to operate it below its minimum compressed height. Operating below this threshold can cause the rubber bladder to become overstretched, leading to premature wear and potential failure. Ensure the air spring is within the correct compression range during use.

Do Not Use at a Pressure Exceeding 0.7 MPa: The air spring must be operated within the specified pressure limits to maintain optimal performance and safety. Exceeding a pressure of 0.7 MPa could lead to over-stretching of the air spring, compromising its structural integrity. Always check and regulate the air pressure according to the manufacturer’s recommendations.

Avoid Twisting the Air Spring: During installation and use, it is important to avoid twisting the air spring. A twisted air spring can lead to uneven distribution of air pressure, causing internal damage or even failure. Make sure the air spring is installed in a straight and aligned position to ensure proper function and durability.

- The GF-Type air spring is typically available in stock.

- The air springs manufactured by Shanghai Songjiang meet national standards and come with a one-year warranty. Any quality issues can be exchanged within this period.

- There is no purchase quantity limit. Small orders are generally shipped via international couriers such as DHL, FEDEX, UPS, TNT, etc., ensuring fast delivery, usually within 3-7 business days.

KL Series Locking Air Spring Model List:

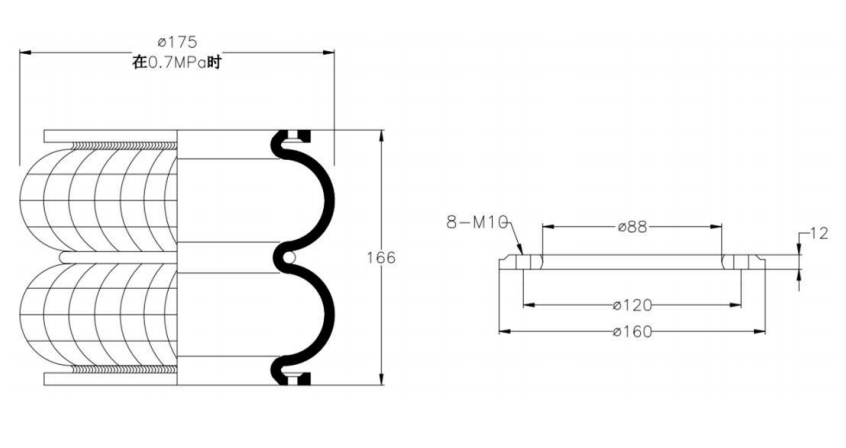

Model:GF 160/166

Maximum Load:1251kg

Maximum Outer Diameter:175mm

Natural Outer Diameter:160mm

Minimum Compressed Height :74mm

Maximum Extended Height :190mm

The weight of the component:1kg

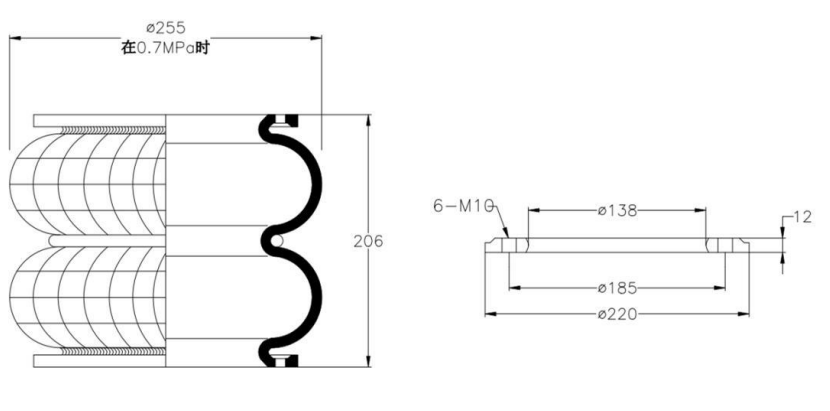

Model:GF 230/206

Maximum Load:2941kg

Maximum Outer Diameter:255mm

Natural Outer Diameter:230mm

Minimum Compressed Height :74mm

Maximum Extended Height :238mm

The weight of the component :2.1kg

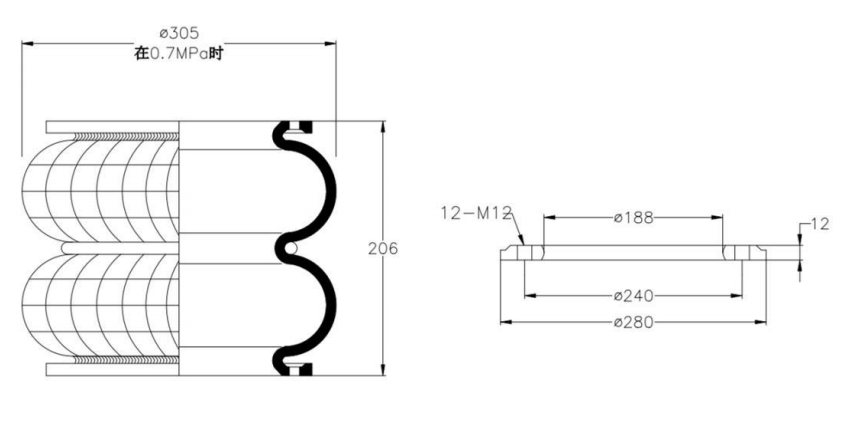

Model:GF 280/206

Maximum Load:4361kg

Maximum Outer Diameter:305mm

Natural Outer Diameter:280mm

Minimum Compressed Height :74mm

Maximum Extended Height :238mm

The weight of the component :2.8kg

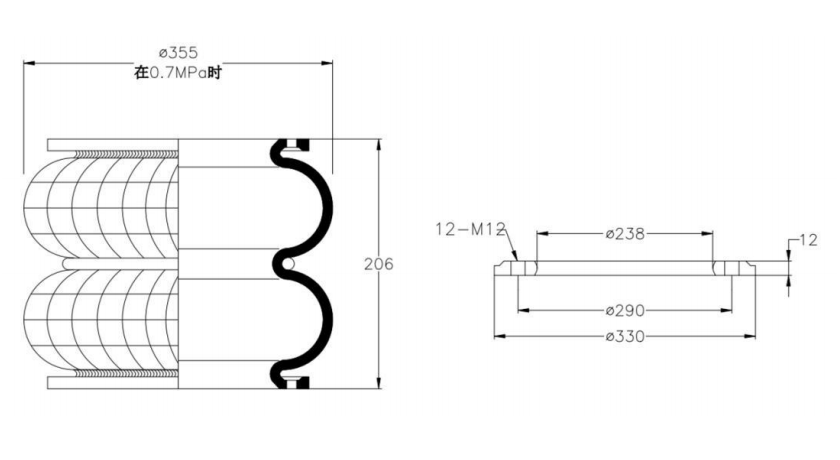

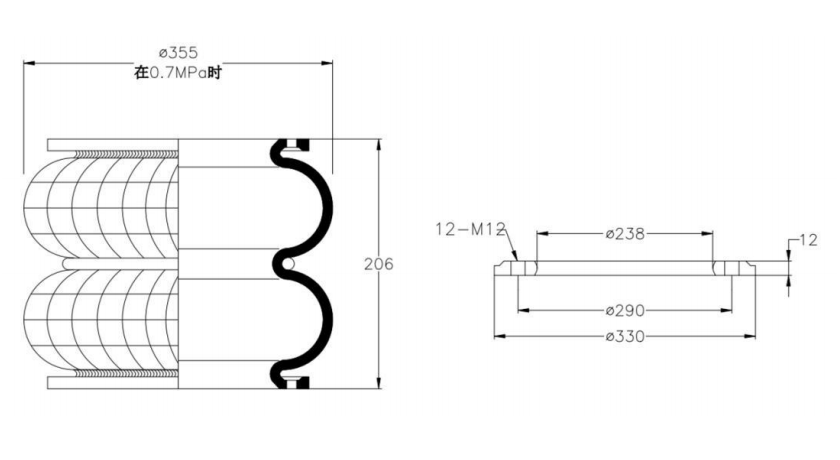

Model:GF 310/206

Maximum Load:5270kg

Maximum Outer Diameter:330mm

Natural Outer Diameter:310mm

Minimum Compressed Height :74mm

Maximum Extended Height :238mm

The weight of the component :3.3kg

Model:GF 330/206

Maximum Load:5966kg

Maximum Outer Diameter:355mm

Natural Outer Diameter:330mm

Minimum Compressed Height :74mm

Maximum Extended Height :238mm

The weight of the component :3.85kg

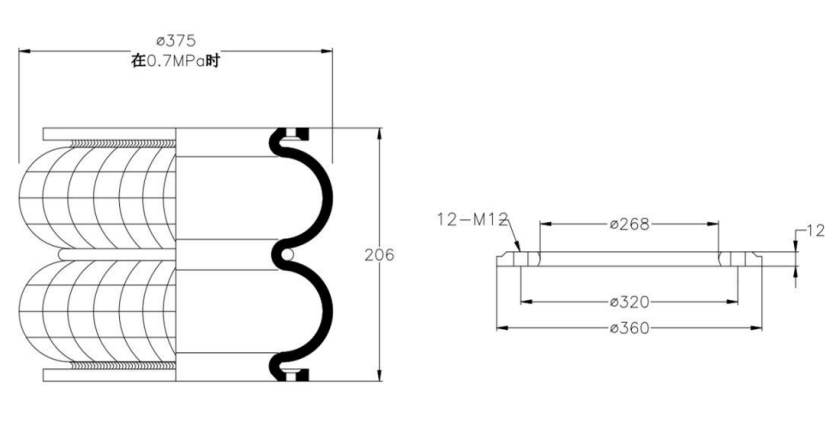

Model:GF C360/206

Maximum Load:6831kg

Maximum Outer Diameter:375mm

Natural Outer Diameter:360mm

Minimum Compressed Height :74mm

Maximum Extended Height :238mm

The weight of the component :3.95kg

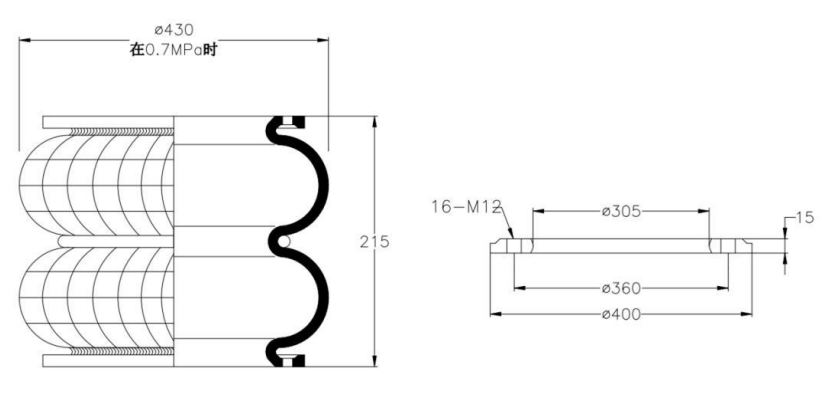

Model:GF 400/215

Maximum Load:8958kg

Maximum Outer Diameter:430mm

Natural Outer Diameter:400mm

Minimum Compressed Height :82mm

Maximum Extended Height :247mm

The weight of the component :4.9kg

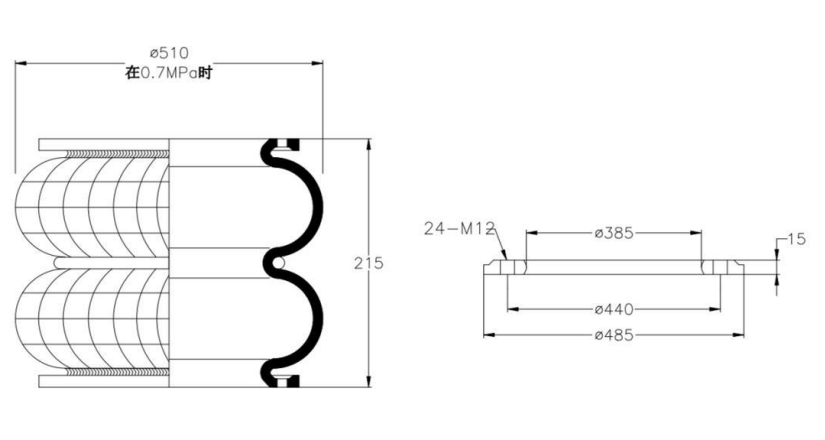

Model:GF 480/215

Maximum Load:13528kg

Maximum Outer Diameter:510mm

Natural Outer Diameter:480mm

Minimum Compressed Height :82mm

Maximum Extended Height :247mm

The weight of the component :6.2kg

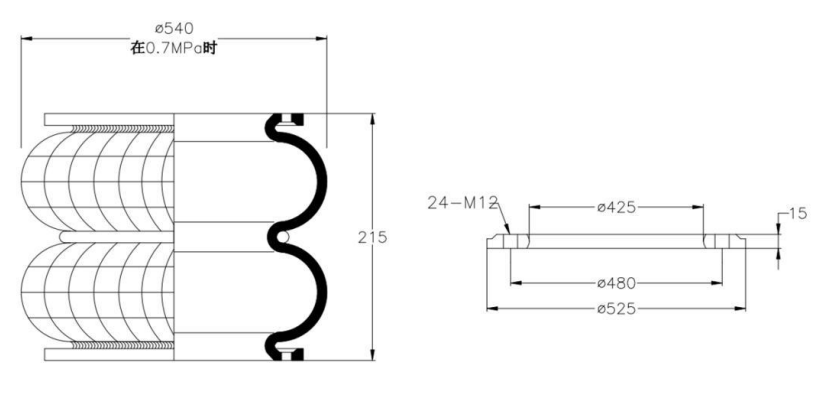

Model:GF 520/215

Maximum Load:14442kg

Maximum Outer Diameter:540mm

Natural Outer Diameter:520mm

Minimum Compressed Height :82mm

Maximum Extended Height :247mm

The weight of the component :7.85kg

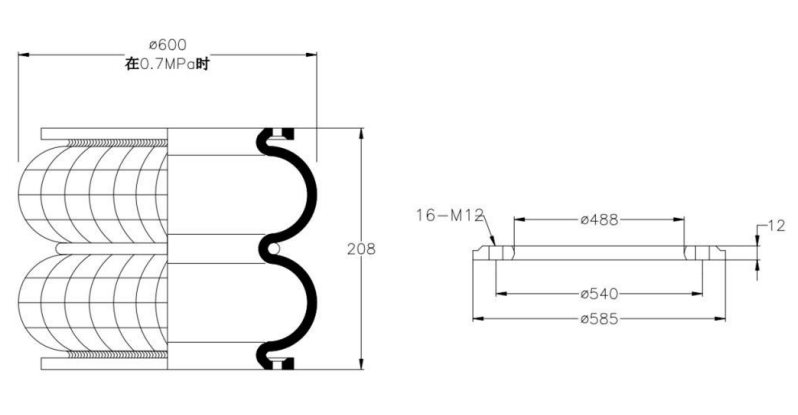

Model:GF 580/208

Maximum Load:18191kg

Maximum Outer Diameter:600mm

Natural Outer Diameter:580mm

Minimum Compressed Height :76mm

Maximum Extended Height :240mm

The weight of the component:8kg

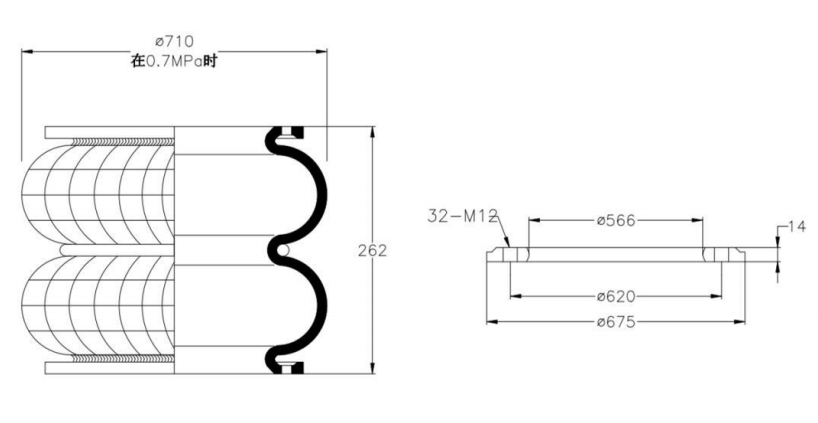

Model:GF 680/208

Maximum Load:kg

Maximum Outer Diameter:710mm

Natural Outer Diameter:680mm

Minimum Compressed Height :90mm

Maximum Extended Height :302mm

The weight of the component :12.5kg

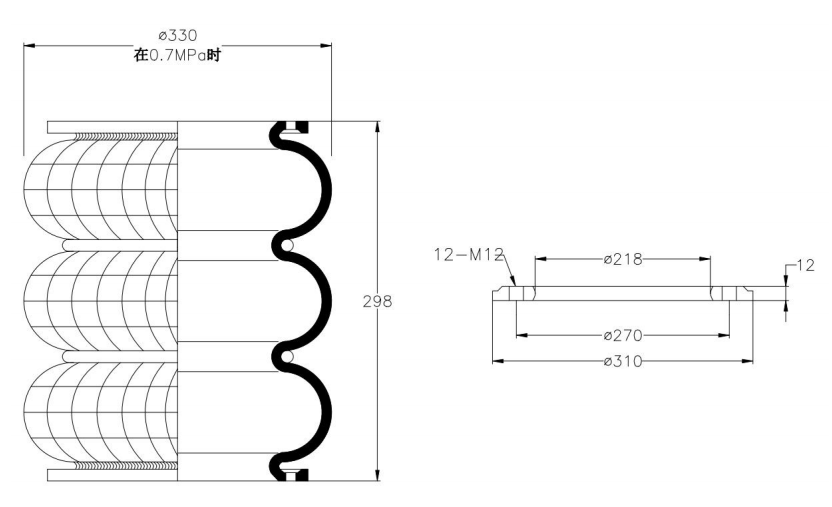

Model:GF 310/298

Maximum Load:5130kg

Maximum Outer Diameter:330mm

Natural Outer Diameter:310mm

Minimum Compressed Height :110mm

Maximum Extended Height :346mm

The weight of the component :5.2kg

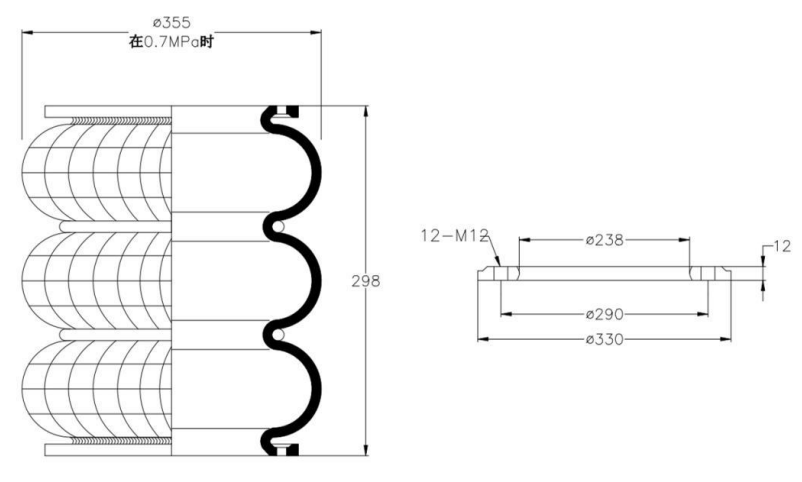

Model:GF 330/298

Maximum Load:5993kg

Maximum Outer Diameter:355mm

Natural Outer Diameter:330mm

Minimum Compressed Height :110mm

Maximum Extended Height :346mm

The weight of the component :5.2kg

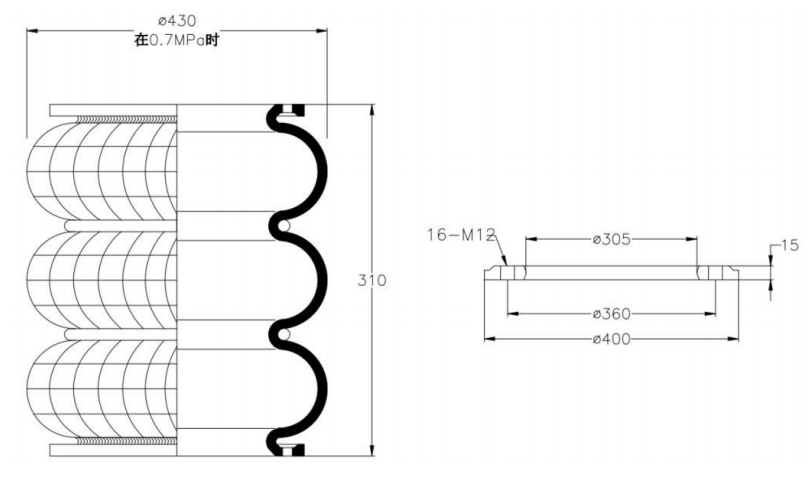

Model:GF 400/310

Maximum Load:8968kg

Maximum Outer Diameter:430mm

Natural Outer Diameter:400mm

Minimum Compressed Height :120mm

Maximum Extended Height :358mm

The weight of the component :6.8kg

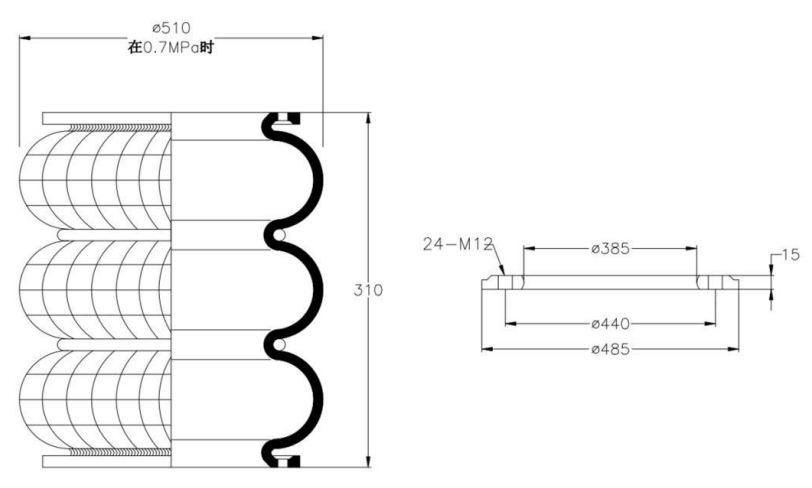

Model:GF 480/310

Maximum Load:12930kg

Maximum Outer Diameter:510mm

Natural Outer Diameter:480mm

Minimum Compressed Height :120mm

Maximum Extended Height :358mm

The weight of the component :10kg

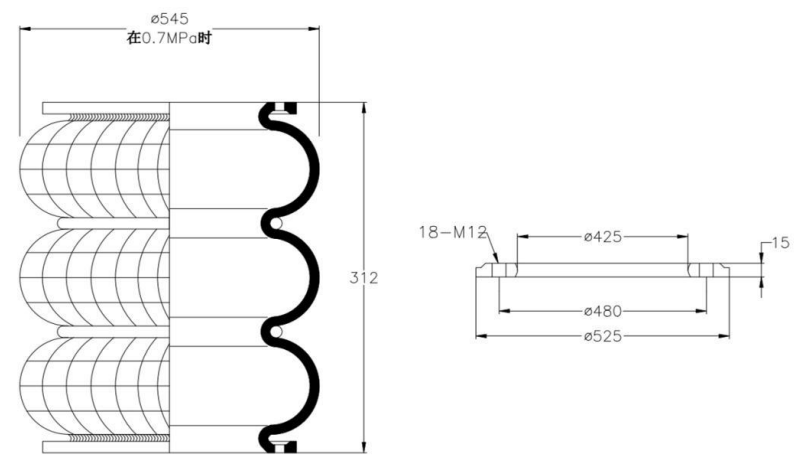

Model:GF 520/310

Maximum Load:14654kg

Maximum Outer Diameter:545mm

Natural Outer Diameter:520mm

Minimum Compressed Height :120mm

Maximum Extended Height :358mm

The weight of the component :12kg

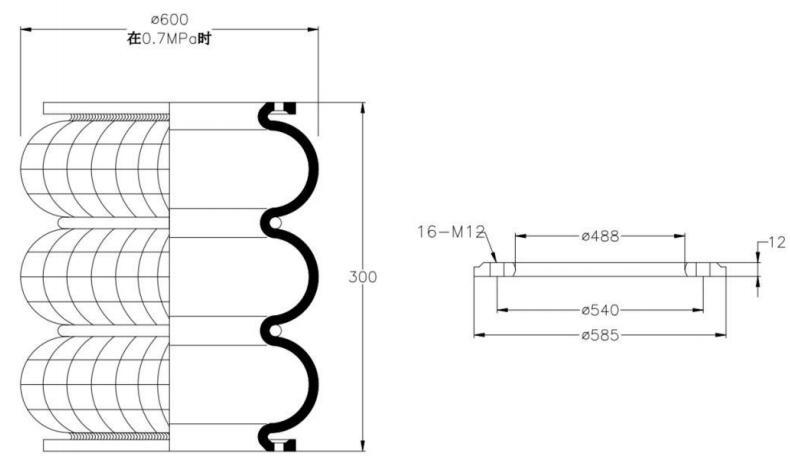

Model:GF 580/306

Maximum Load:18289kg

Maximum Outer Diameter:600mm

Natural Outer Diameter:580mm

Minimum Compressed Height :112mm

Maximum Extended Height :348mm

The weight of the component :12kg

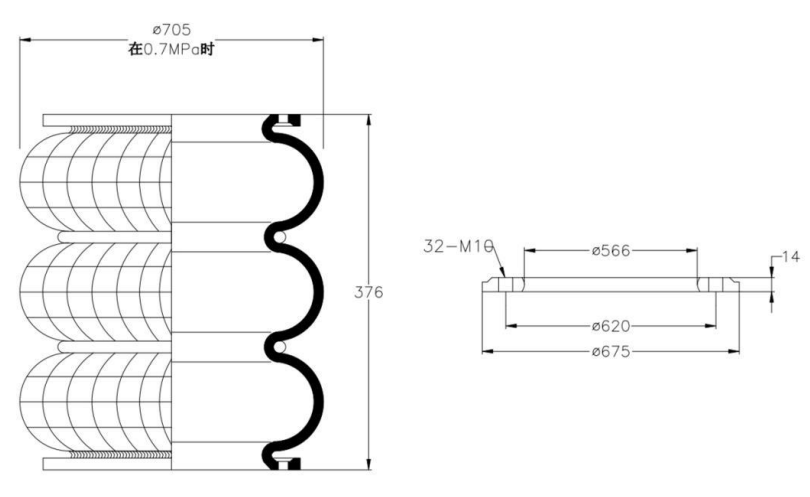

Model:GF 680/376

Maximum Load:22048kg

Maximum Outer Diameter:705mm

Natural Outer Diameter:680mm

Minimum Compressed Height :122mm

Maximum Extended Height :436mm

The weight of the component :18kg