FS Type Single Bellow Air Sping

FS Type Edge-wrapped plate integrated rubber air spring

Frequently Asked Questions

What are the benefits of using a FS-Type Rubber Air Spring?

FS-Type Rubber Air Springs offer a range of benefits that make them highly suitable for industrial vibration isolation and load-bearing applications:

Excellent Vibration Isolation

The flexible rubber air chamber effectively absorbs and isolates both high- and low-frequency vibrations, reducing noise and protecting sensitive equipment.Adjustable Load and Height

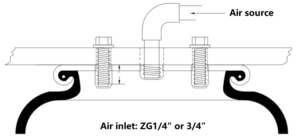

Air pressure inside the spring can be adjusted to accommodate different load conditions, making it ideal for dynamic systems such as HVAC units, compressors, and platforms.Modular Design with Movable Flange

Each FS-type air spring is equipped with a movable flange, allowing the user to easily assemble it with an additional blind plate using bolts. This design makes installation, removal, and replacement of the rubber airbag extremely convenient—especially useful when only the rubber part is damaged.Long Service Life

Made from high-strength, wear-resistant rubber (like neoprene), FS-Type air springs are built for thousands of compression cycles in harsh environments without loss of performance.Low Maintenance

Unlike metal springs, FS air springs operate without metal-to-metal contact, requiring no lubrication and minimal maintenance over time.Compact and Lightweight

The cylindrical design allows for easy integration into tight or limited spaces, while still delivering high load capacity.

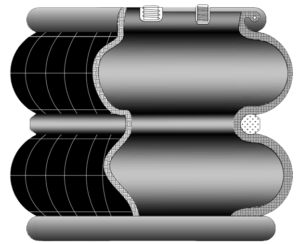

How Does the FS-Type Rubber Air Spring Function?

The FS-Type air spring functions by utilizing a rubber airbag that compresses and expands to absorb shocks and vibrations. As a load is applied, the internal air pressure adjusts to match the weight, enabling the air spring to maintain a steady height and efficiently isolate vibrations from external sources. Its design incorporates sealed end plates, eliminating the need for additional components and ensuring easy installation. This construction provides superior vibration dampening and impact absorption, improving comfort and safety. These air springs are ideal for use in various machinery and vehicles, delivering reliable performance in diverse applications.

This version rephrases the original text in a unique way to ensure it is optimized for search engines while conveying the same message.

What are the applications of the FS-Type Rubber Air Spring?

The FS-Type Rubber Air Spring is used in a wide range of applications, including:

- Mould separation machines (air cushions)

- Roll leveling machines (airbags)

- Three-dimensional vibration tables (air bladders)

- Rubber vibration tables (air cushions)

- Roller friction brake machines (air springs)

- Conveyors (air pads)

- Straightening machines (air springs)

- Vehicle air suspension systems

- Gate valve actuator air springs

- Forming presses (air bladders)

- Cable tensioners (airbags)

- Pipe threading machines (air pads)

- Tobacco machinery (airbags)

- Analytical instruments (airbags)

- Secondary lifting equipment (air bladders)

- Missile transport equipment (air bladders)

- Aircraft airbags

- Trampolines (air cushions)

- High-frequency vibration tables (air bladders)

This demonstrates the versatility of the FS-Type Rubber Air Spring across various industries and machinery types.

Do Not Exceed the Recommended Safe Extended Height: When installing or using an air spring, ensure that it is not extended beyond the recommended height. Exceeding this height could lead to excessive strain on the air spring, resulting in damage or reduced performance over time. Always follow the manufacturer’s guidelines regarding the safe extended height for proper operation.

Avoid Using Below the Minimum Compressed Height: To prolong the lifespan of the air spring, it is crucial not to operate it below its minimum compressed height. Operating below this threshold can cause the rubber bladder to become overstretched, leading to premature wear and potential failure. Ensure the air spring is within the correct compression range during use.

Do Not Use at a Pressure Exceeding 0.7 MPa: The air spring must be operated within the specified pressure limits to maintain optimal performance and safety. Exceeding a pressure of 0.7 MPa could lead to over-stretching of the air spring, compromising its structural integrity. Always check and regulate the air pressure according to the manufacturer’s recommendations.

Avoid Twisting the Air Spring: During installation and use, it is important to avoid twisting the air spring. A twisted air spring can lead to uneven distribution of air pressure, causing internal damage or even failure. Make sure the air spring is installed in a straight and aligned position to ensure proper function and durability.

- The FS-Type air spring is typically available in stock.

- The air springs manufactured by Shanghai Songjiang meet national standards and come with a one-year warranty. Any quality issues can be exchanged within this period.

- There is no purchase quantity limit. Small orders are generally shipped via international couriers such as DHL, FEDEX, UPS, TNT, etc., ensuring fast delivery, usually within 3-7 business days.

FS Type Single Bellow Air Sping Model List:

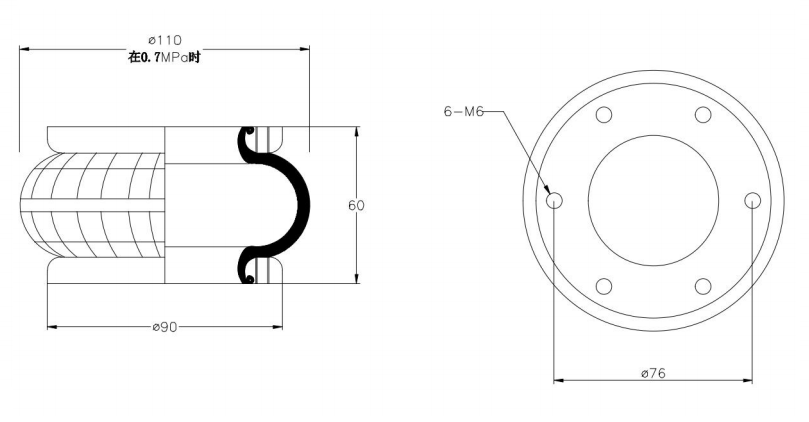

Model:FS 80/60

Maximum Load:317kg

Maximum Outer Diameter:110mm

Natural Outer Diameter:86mm

Minimum Compressed Height :42mm

Maximum Extended Height:90mm

The weight of the component:1kg

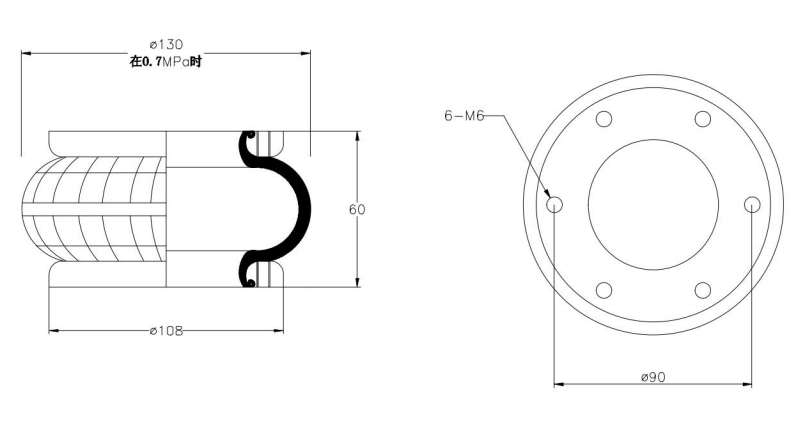

Model:FS 120/60

Maximum Load:742kg

Maximum Outer Diameter:130mm

Natural Outer Diameter:120mm

Minimum Compressed Height :42mm

Maximum Extended Height:65mm

The weight of the component :1.6kg

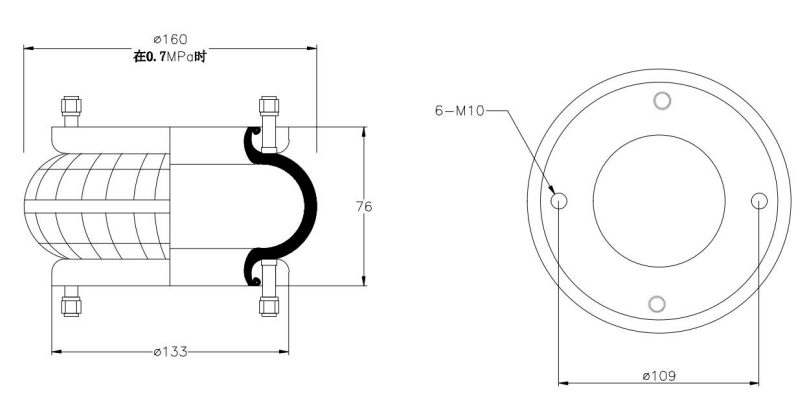

Model:FS 150/76

Maximum Load:1155kg

Maximum Outer Diameter:160mm

Natural Outer Diameter:150mm

Minimum Compressed Height :45mm

Maximum Extended Height:85mm

The weight of the component :1.4kg

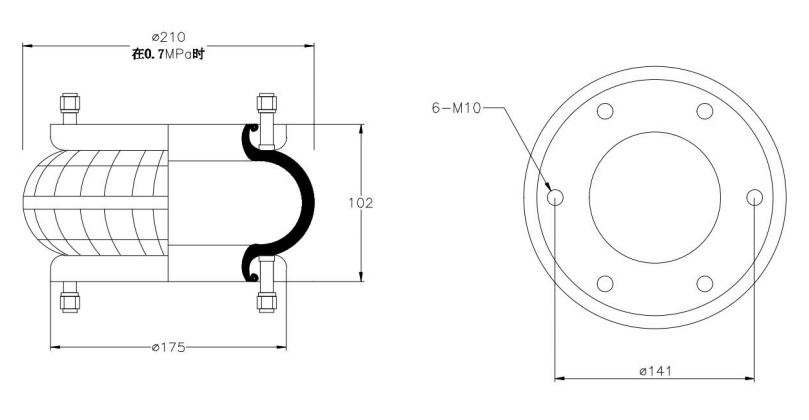

Model:FS 188/102

Maximum Load:1871kg

Maximum Outer Diameter:210mm

Natural Outer Diameter:188mm

Minimum Compressed Height :52mm

Maximum Extended Height :117mm

The weight of the component :2.25kg

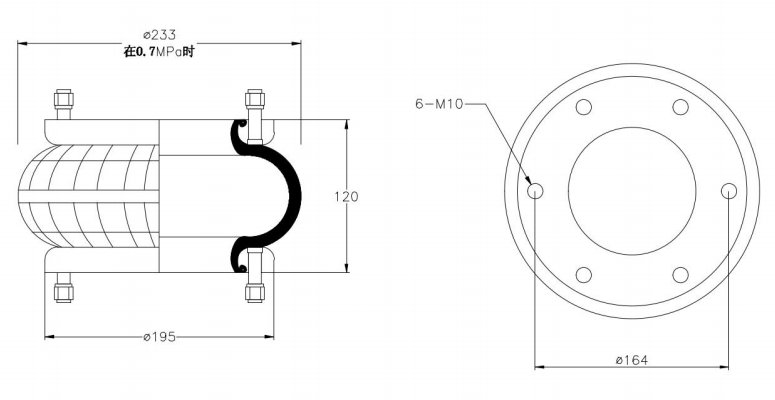

Model:FS 215/120

Maximum Load:2459kg

Maximum Outer Diameter:233mm

Natural Outer Diameter:215mm

Minimum Compressed Height :42mm

Maximum Extended Height :140mm

The weight of the component :2.9kg

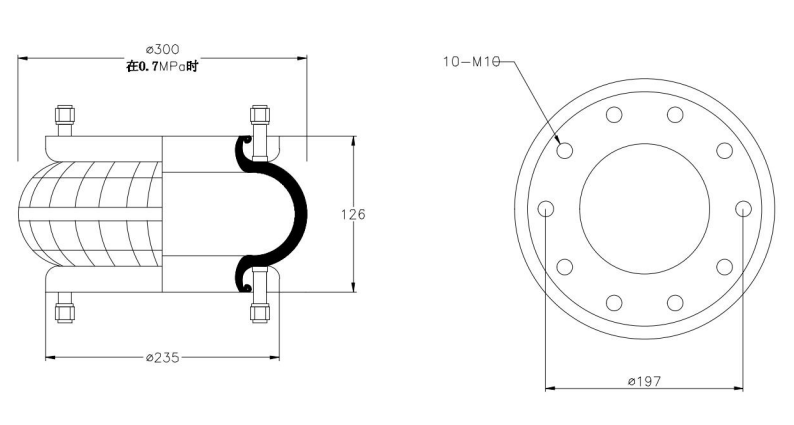

Model:FS 280/126

Maximum Load:3799kg

Maximum Outer Diameter:300mm

Natural Outer Diameter:280mm

Minimum Compressed Height :60mm

Maximum Extended Height :144mm

The weight of the component :3.75kg

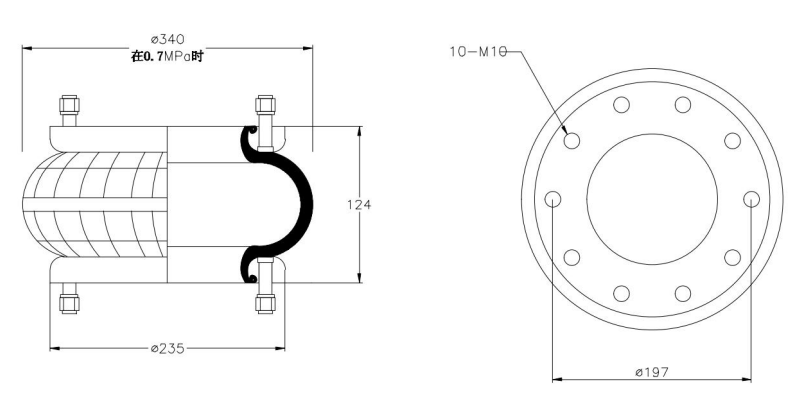

Model:FS 320/124

Maximum Load:4177kg

Maximum Outer Diameter:340mm

Natural Outer Diameter:320mm

Minimum Compressed Height :60mm

Maximum Extended Height :142mm

The weight of the component :3.9kg