KQJZ-A Type Air lsolator

KQJZ-A Type Air lsolator

Frequently Asked Questions

What systems are KQJZ-A Type Air lsolator used in?

The KQJZ-A type air isolators are commonly used in systems that require vibration isolation and damping, including:

- HVAC Systems: For isolating air conditioning, ventilation, and heating units to reduce noise and vibrations.

- Mechanical Equipment: In machinery and equipment that produce vibrations, such as compressors, pumps, and motors.

- Industrial Applications: For isolating sensitive equipment in factories or production lines.

- Transportation Systems: In railways, subways, and other vehicles to reduce vibrations and noise.

- Testing and Calibration Equipment: In laboratories and other environments where sensitive instruments need to be shielded from external vibrations.

These isolators are particularly effective in preventing vibration transmission, protecting equipment, and maintaining system stability.

How does the KQJZ-A Type Air lsolator work?

The KQJZ-A type air isolator works by using air pressure to create a cushioning effect that absorbs and dampens vibrations. Here’s how it functions:

Air Cushion: The isolator has an air chamber that acts as a cushion. When vibrations or shocks occur, the air inside the chamber compresses and absorbs the impact, reducing the transfer of energy to the system.

Pressure Adjustment: The isolator is designed to maintain a specific air pressure. This allows for dynamic adjustment, depending on the load or external forces acting on the system, ensuring consistent isolation performance.

Elasticity: The air chamber’s elasticity helps it adapt to varying vibrations, providing flexibility to absorb both small and large shocks. This elasticity reduces the amplitude of vibrations, preventing them from reaching sensitive equipment.

Isolation and Damping: The isolator separates the equipment from the source of vibration by isolating it with air pressure, preventing vibrations from being transmitted to other parts of the system. Additionally, the internal damping mechanisms help further reduce oscillations and ensure smooth operation.

This combination of air cushioning, adjustable pressure, and damping ensures that the KQJZ-A air isolator provides effective vibration isolation in a wide range of applications.

What are the product advantages of KQJZ-A Type Air lsolator ?

The KQJZ-A Type Air Isolator offers several advantages:

Effective Vibration Isolation: It efficiently absorbs and isolates vibrations, preventing them from being transmitted to sensitive equipment or systems. This is crucial for applications in machinery, HVAC systems, and transportation.

Adjustable Air Pressure: The isolator can be adjusted to suit different loads or operational conditions, allowing for flexibility and optimized performance across various applications.

Durability and Longevity: Made from high-quality materials, the KQJZ-A air isolator is resistant to wear, corrosion, and environmental factors, ensuring long-lasting performance even in demanding conditions.

Low Maintenance: Due to its simple design and robust construction, the air isolator requires minimal maintenance, making it cost-effective in the long term.

Noise Reduction: In addition to vibration isolation, the air isolator helps reduce noise generated by machinery and mechanical systems, providing a quieter and more comfortable environment.

Customizable: The isolator can be tailored to meet specific requirements, including size, load capacity, and pressure specifications, allowing it to fit a wide range of industrial applications.

Enhanced Stability: It helps maintain the stability and performance of sensitive equipment, preventing damage and ensuring accurate operation in testing and calibration systems.

These advantages make the KQJZ-A type air isolator an excellent choice for a variety of industrial, mechanical, and transportation applications.

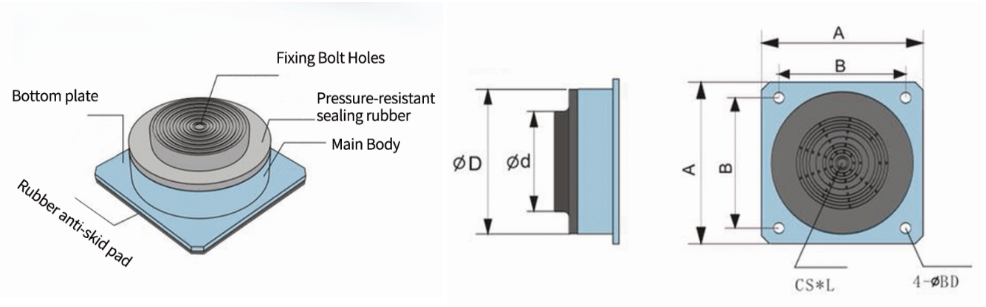

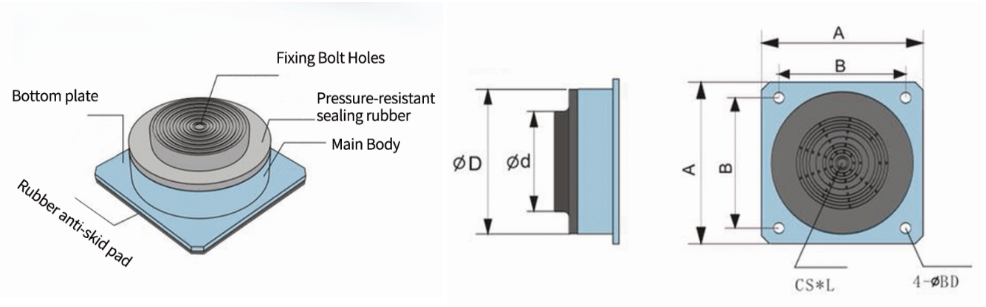

The KQJZ-A Type Air Isolator typically features several design elements that contribute to its performance in vibration isolation and damping. Common design features include:

Air Chamber: The core design of the isolator consists of an air-filled chamber. This chamber acts as a cushion, compressing and expanding in response to external vibrations or shocks.

Elastic Material: The isolator often uses elastic materials (such as rubber or synthetic polymers) around the air chamber to provide additional flexibility and damping, further enhancing vibration isolation.

Adjustable Pressure Mechanism: Many designs of KQJZ-A isolators come with a built-in mechanism that allows for adjusting the internal air pressure. This feature helps to maintain the optimal isolation performance under different load conditions.

Steel or Alloy Housing: The isolator’s outer casing is typically made from strong, durable materials such as steel or alloy, ensuring structural integrity and resistance to mechanical stress and environmental conditions.

Spring Mechanism (Optional): Some designs incorporate a spring inside the isolator to complement the air cushion, offering extra support for specific vibration frequencies or heavy loads.

Connection Points: The isolator is designed with attachment points, such as threaded bolts or flanges, to securely connect it to machinery, equipment, or support structures.

Height Adjustment Features: To provide further flexibility, some designs include adjustable height options, allowing users to fine-tune the isolator to the specific requirements of the application.

Sealed Construction: The isolator may include sealing elements to prevent air leakage, ensuring long-term consistent performance and maintaining the internal air pressure.

Corrosion-Resistant Coating: To protect against environmental factors, many KQJZ-A isolators feature a corrosion-resistant coating or surface treatment, increasing their durability in outdoor or industrial settings.

When installing and using the KQJZ-A Type Air Isolator, there are several important precautions to ensure optimal performance and longevity:

Installation Precautions:

Proper Alignment: Ensure that the isolator is installed in a straight and level position. Misalignment can reduce its efficiency and cause uneven wear.

Correct Load Capacity: Verify that the isolator is designed for the specific load requirements of the system. Overloading the isolator can lead to failure or reduced vibration isolation performance.

Secure Mounting: Use the appropriate fasteners and secure the isolator tightly to prevent any movement during operation. Loose installations can lead to instability and decreased effectiveness.

Air Pressure Calibration: Before use, calibrate the internal air pressure according to the manufacturer’s specifications. Incorrect pressure levels can affect the isolator’s performance and its ability to absorb vibrations.

No Obstructions: Ensure there are no obstructions around the isolator that could hinder air flow or affect its ability to absorb vibrations effectively.

Surface Preparation: The mounting surfaces should be smooth and free of debris or dirt to ensure a proper seal and stable installation.

Usage Precautions:

Avoid Over-Pressurization: Do not exceed the recommended air pressure limits. Over-pressurizing can damage the isolator and reduce its lifespan.

Regular Monitoring: Check the air pressure regularly to ensure that it remains within the optimal range. Low pressure can reduce vibration isolation effectiveness, while high pressure can cause excessive wear.

Environmental Considerations: Avoid exposing the isolator to extreme temperatures, corrosive chemicals, or other harsh environmental conditions unless it is specifically designed for such use.

Vibration Frequency Compatibility: Ensure that the isolator is suitable for the specific vibration frequencies of your system. Some isolators may not perform well at certain frequencies or speeds.

Routine Maintenance: Inspect the isolator periodically for wear, leaks, or other signs of damage. Perform any necessary maintenance or replace damaged isolators to prevent system failure.

Avoid Heavy Impact: While the isolator is designed to absorb vibrations, it is not intended to withstand direct, heavy impacts or shocks. Avoid subjecting the isolator to sudden, extreme forces.

Storage Precautions:

Store in a Dry Place: When not in use, store the isolator in a clean, dry, and cool environment to prevent damage from moisture or exposure to extreme temperatures.

Keep Away from Chemicals: Ensure the isolator is kept away from aggressive chemicals or substances that could degrade the material or seals.

By following these precautions, you can maximize the performance and lifespan of the KQJZ-A Type Air Isolator, ensuring reliable vibration isolation for your systems.

- KQJZ-A Type Air lsolator are typically available in stock.

- KQJZ-A Type Air lsolator manufactured by Shanghai Songjiang meet national standards and come with a one-year warranty. Any quality issues can be exchanged within this period.

- There is no purchase quantity limit. Small orders are generally shipped via international couriers such as DHL, FEDEX, UPS, TNT, etc., ensuring fast delivery, usually within 3-7 business days.

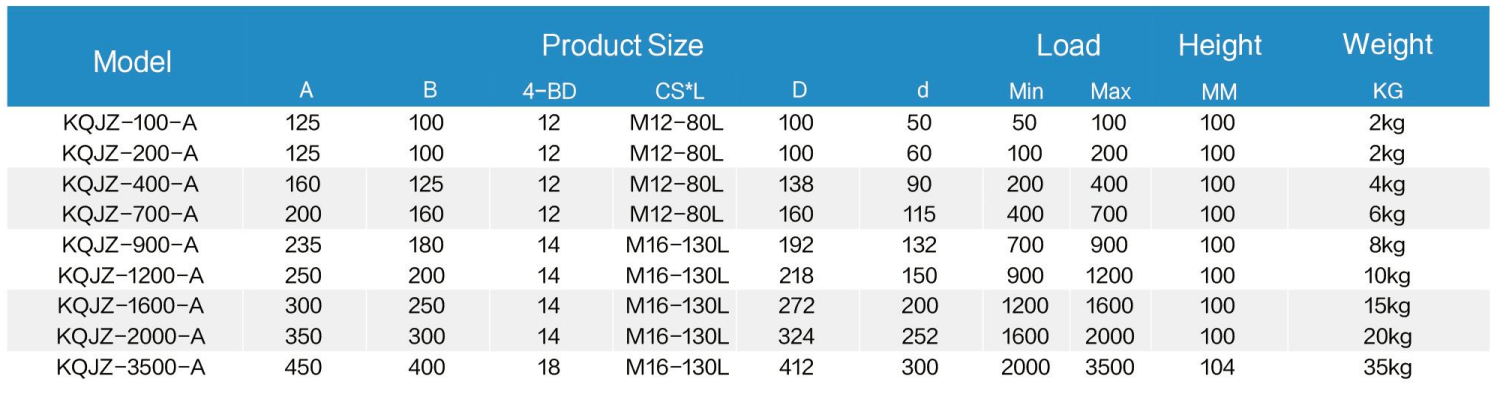

KQJZ-A Type Air lsolator Model List :