Air Spring for Trailer Axles

AIRSPRINGO air spring systems offer over 500 product lines worldwide, covering almost all commonly used air spring models for trailers, trucks, and buses. The products are guaranteed to meet the highest quality standards while also complying with the specifications of vehicle manufacturers active in the aftermarket.————Air Spring for Trailer Axles are components used in the suspension system of trailers to provide cushioning and support. They help absorb shocks and vibrations from the road, ensuring a smoother ride and improving stability. These air springs allow for adjustable load capacities, enhancing the performance of trailers under varying conditions. They are commonly used in heavy-duty trailers, ensuring better weight distribution, reduced wear on other suspension components, and improved overall vehicle handling.

Air Spring for Trailer Axles

Frequently Asked Questions

What are the benefits of using Air Spring for Trailer Axles?

The benefits of using Air Springs for Trailer Axles include:

Improved Ride Comfort: Air springs absorb shocks and vibrations, providing a smoother ride for the trailer and reducing the impact of road irregularities.

Enhanced Load Distribution: They help distribute the weight evenly across the trailer, improving balance and stability, especially under varying load conditions.

Adjustable Load Capacity: Air springs can be adjusted to suit different load requirements, offering greater flexibility for transporting various types of cargo.

Reduced Wear on Suspension Components: By absorbing shocks, air springs reduce the strain on other suspension parts, prolonging the life of the trailer’s suspension system.

Increased Stability: Air springs improve the trailer’s stability, making it easier to handle on the road, especially when carrying heavy or uneven loads.

Better Fuel Efficiency: By reducing the impact of road shocks and vibrations, air springs can contribute to better fuel efficiency, as the vehicle’s suspension system operates more efficiently.

Enhanced Safety: Improved handling, stability, and load control contribute to safer driving conditions, reducing the risk of accidents.

How Does the air spring for trailer axles Function?

The air spring for trailer axles works by utilizing the compression and expansion of air to provide suspension support, absorb shocks, and reduce vibrations, ensuring a smoother ride for the trailer. Here’s how it functions:

Airbag Structure: Air springs are typically made from durable rubber and fabric materials, with steel brackets supporting the outer structure. The airbag is filled with air, giving it elasticity.

Compression and Expansion: When the trailer passes over uneven surfaces, the airbag compresses, forcing the air inside to be displaced, thus absorbing the impact from the road. When the surface smoothens, the airbag expands back to its original shape, as air re-enters the system.

Shock Absorption: The airbag absorbs vibrations by compressing and expanding, reducing the impact of road irregularities on the trailer, cargo, and the vehicle itself, ensuring a smoother transport experience.

Adjustable Load Capacity: The air pressure inside the air spring can be adjusted to accommodate different load conditions. For instance, when the load is heavier, the air pressure increases, providing more support. When the load is lighter, the pressure can be reduced, making the air spring more flexible.

Balance and Stability: Air springs can adjust the pressure on each axle according to the load, allowing for better load distribution and stability. This reduces axle sway, especially when driving at high speeds or turning, improving road safety.

Reduced Wear: The cushioning effect of the air spring reduces shock and friction on other suspension components, extending the lifespan of the suspension system and other vehicle parts.

In summary, trailer air springs provide flexible support, absorb shocks, adjust load capacity, and improve stability, ensuring smooth and safe operation of the trailer under various road and load conditions.

What are the applications of the air spring for trailer axles?

The air spring for trailer axles has a variety of applications, particularly in the transportation and logistics sectors. Here are some of the key applications:

Heavy-Duty Trailers: Air springs are commonly used in heavy-duty trailers, including flatbeds, lowboys, and box trailers, to improve ride comfort and stability while carrying heavy loads.

Cargo Transport: For trailers carrying sensitive or fragile cargo, air springs help reduce vibrations and shocks, protecting the goods from damage during transportation.

Refrigerated Trailers (Reefers): Air springs are used in refrigerated trailers to maintain smooth transportation of perishable goods. The reduced vibrations and improved stability help preserve the quality of temperature-sensitive cargo.

Construction and Industrial Trailers: Trailers used for transporting construction equipment, machinery, and industrial goods benefit from air springs, which provide better load control and shock absorption on rough terrain.

Tankers and Liquid Transport: Air springs help stabilize tankers carrying liquids by reducing the effects of sloshing and improving ride quality, which is especially important when transporting hazardous materials.

Automotive Transport: In trailers used for transporting cars or other vehicles, air springs help ensure smooth travel and prevent damage to the vehicles being transported.

Buses and Coach Trailers: Air springs are often found in bus and coach trailers to improve passenger comfort by reducing road vibrations and enhancing the overall ride quality.

Agricultural Trailers: Air springs in agricultural trailers help distribute the load evenly, improving stability and handling, especially when transporting crops or farming equipment.

Freight and Logistics: Air springs improve the efficiency of freight trailers, ensuring a smoother ride, especially over long distances, and contributing to better fuel economy by minimizing vibrations.

In summary, air springs for trailer axles are used in a wide range of applications, including heavy-duty cargo transport, construction, automotive, agricultural, and passenger services, all of which benefit from enhanced ride comfort, load stability, and durability.

Do Not Exceed the Recommended Safe Extended Height: When installing or using an air spring, ensure that it is not extended beyond the recommended height. Exceeding this height could lead to excessive strain on the air spring, resulting in damage or reduced performance over time. Always follow the manufacturer’s guidelines regarding the safe extended height for proper operation.

Avoid Using Below the Minimum Compressed Height: To prolong the lifespan of the air spring, it is crucial not to operate it below its minimum compressed height. Operating below this threshold can cause the rubber bladder to become overstretched, leading to premature wear and potential failure. Ensure the air spring is within the correct compression range during use.

Do Not Use at a Pressure Exceeding 0.7 MPa: The air spring must be operated within the specified pressure limits to maintain optimal performance and safety. Exceeding a pressure of 0.7 MPa could lead to over-stretching of the air spring, compromising its structural integrity. Always check and regulate the air pressure according to the manufacturer’s recommendations.

Avoid Twisting the Air Spring: During installation and use, it is important to avoid twisting the air spring. A twisted air spring can lead to uneven distribution of air pressure, causing internal damage or even failure. Make sure the air spring is installed in a straight and aligned position to ensure proper function and durability.

- The air spring for trailer axles are typically available in stock.

- The air springs manufactured by Shanghai Songjiang meet national standards and come with a one-year warranty. Any quality issues can be exchanged within this period.

- There is no purchase quantity limit. Small orders are generally shipped via international couriers such as DHL, FEDEX, UPS, TNT, etc., ensuring fast delivery, usually within 3-7 business days.

Air Spring for Trailer Axles Model List:

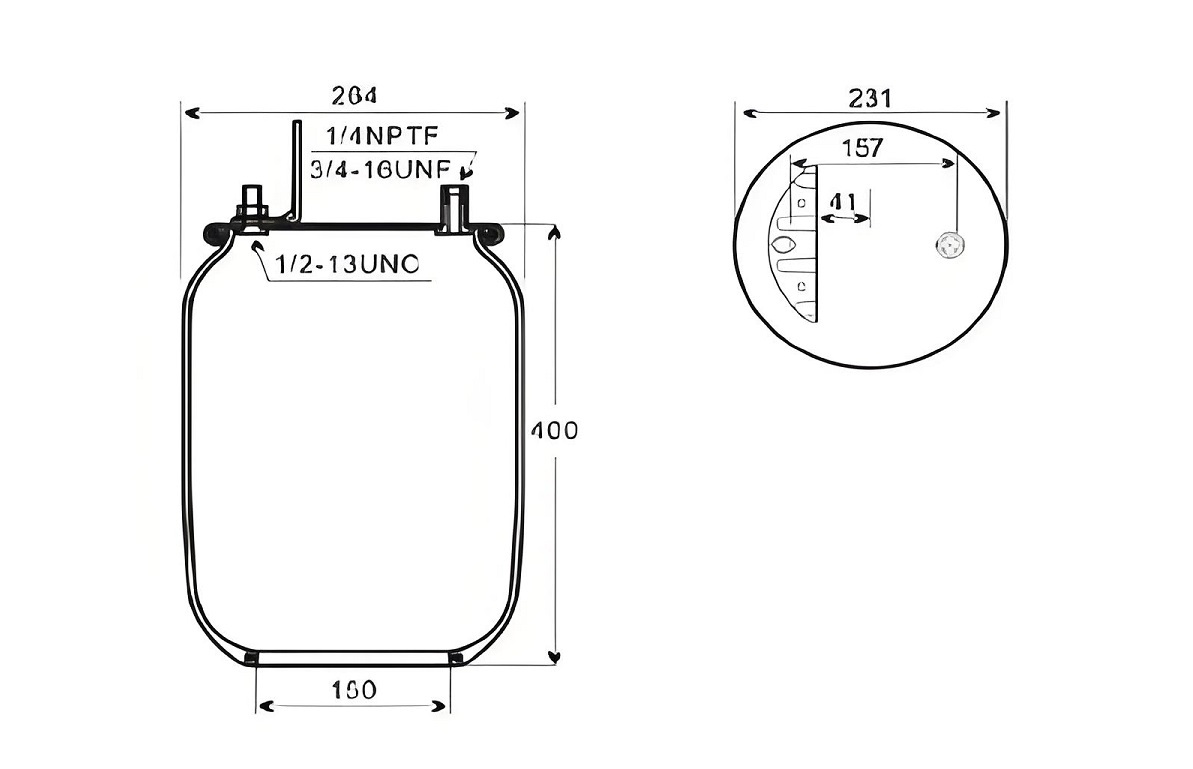

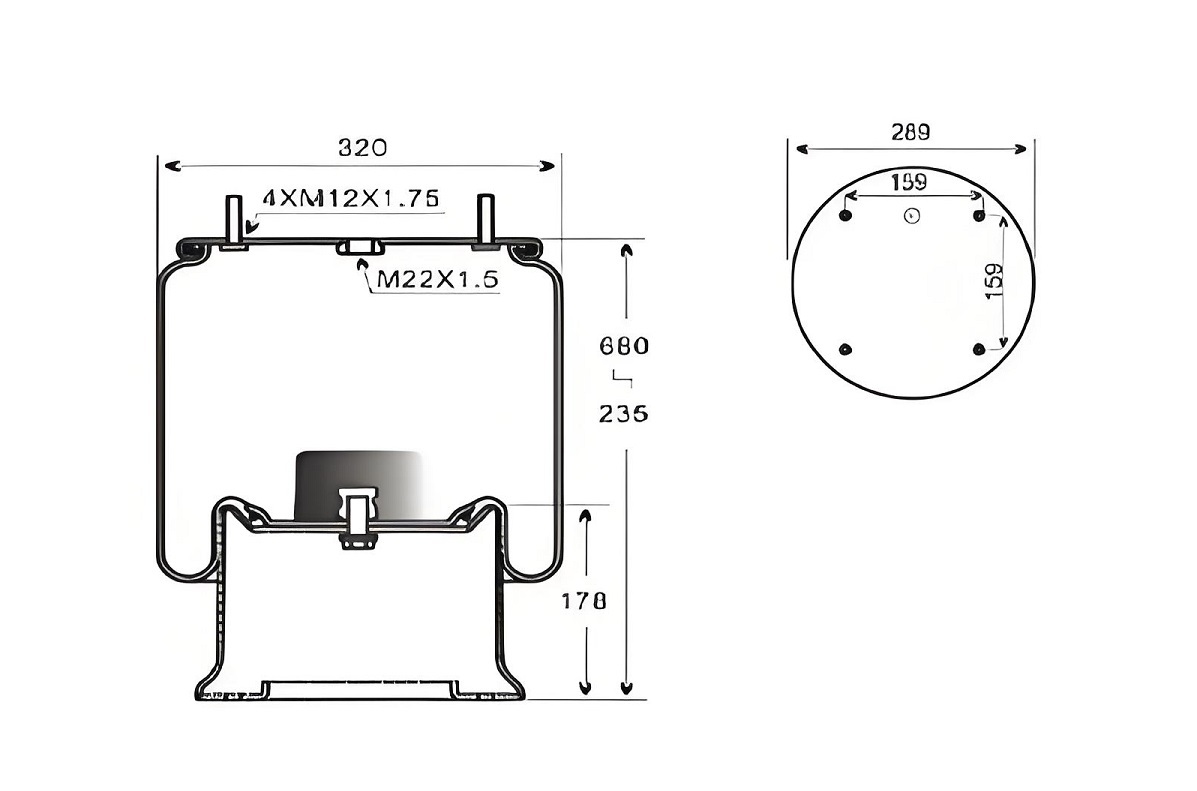

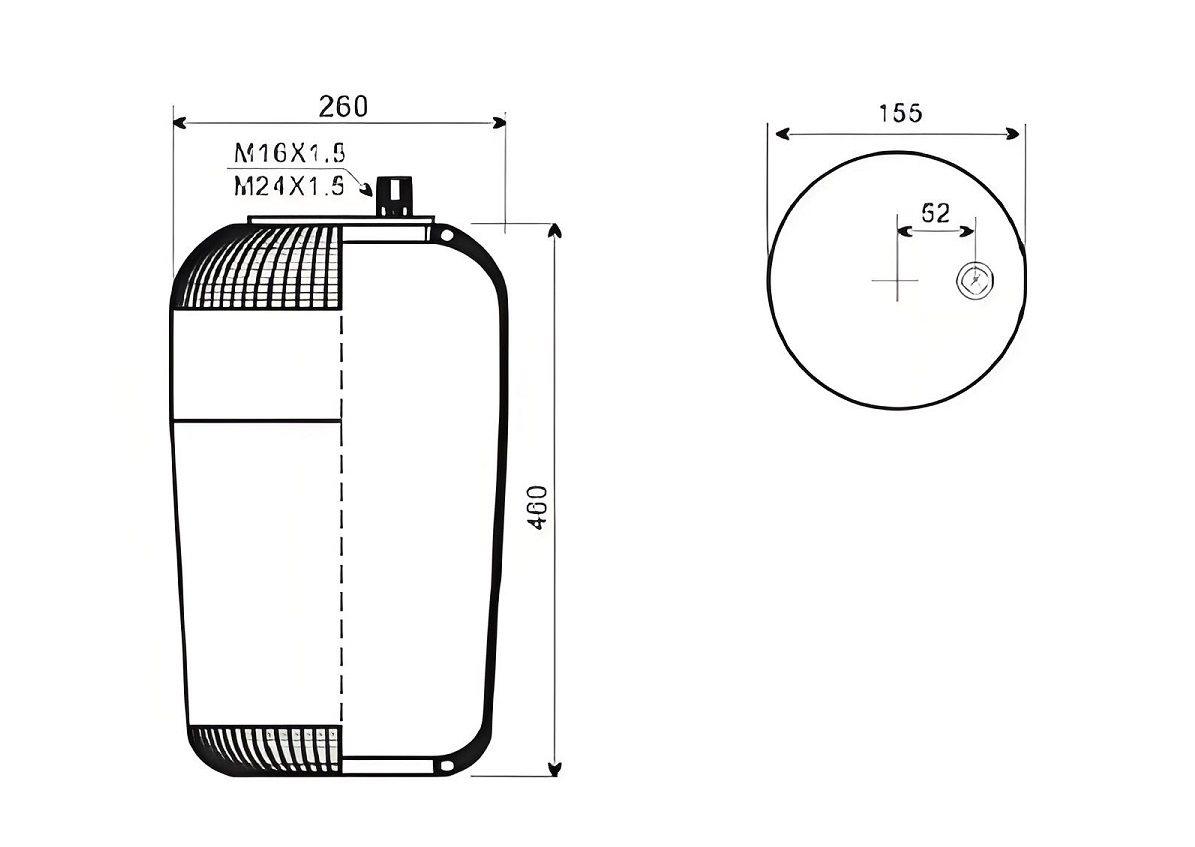

Model:1V 9781 SA

Firestone: W01-358-9781

Contitech: 910S-16A382

Goodyear: 1R12-603

Freightliner: 681-320-0017

A416-14004-000/Aluminum Piston

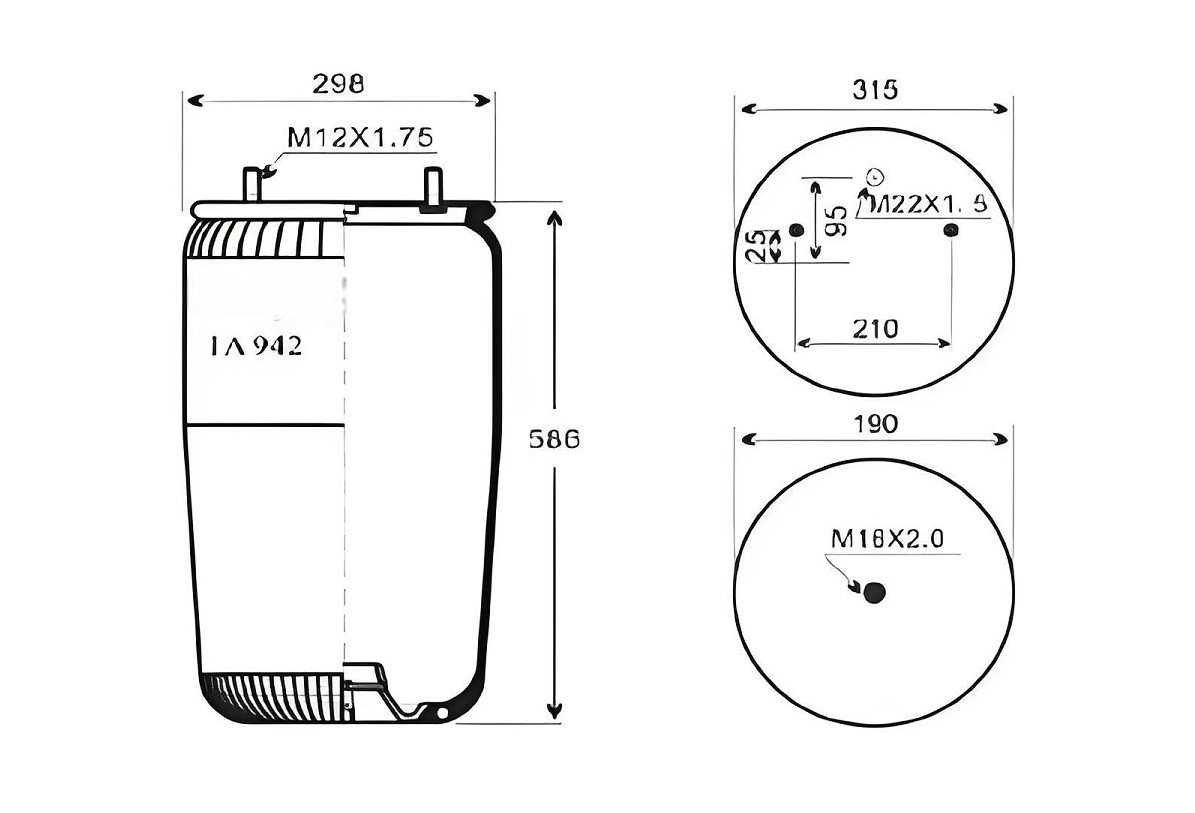

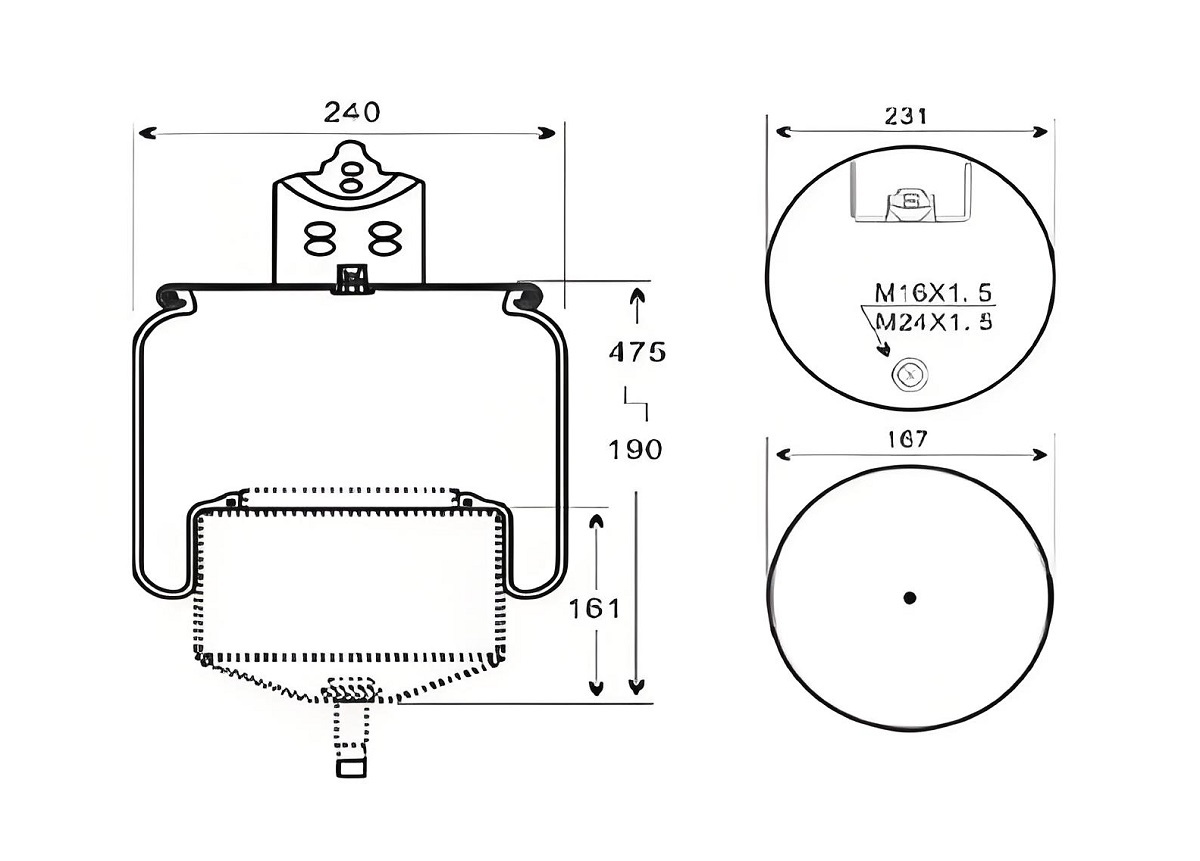

Model:1V 8611 SA

Firestone: W01-M58-8611 / 1T66F-13.5

Contitech: 942MB / 50247

Goodyear: 1R14-700

Phoenix: 1DK32-1

Taurus: UR837-01T

Airtech: 120542 / 3942P

WABCO: 9518147000

Granning: 15902

Meritor: MLF7043

BPW: 05.429.40.05.0

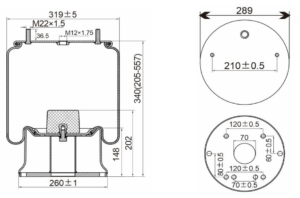

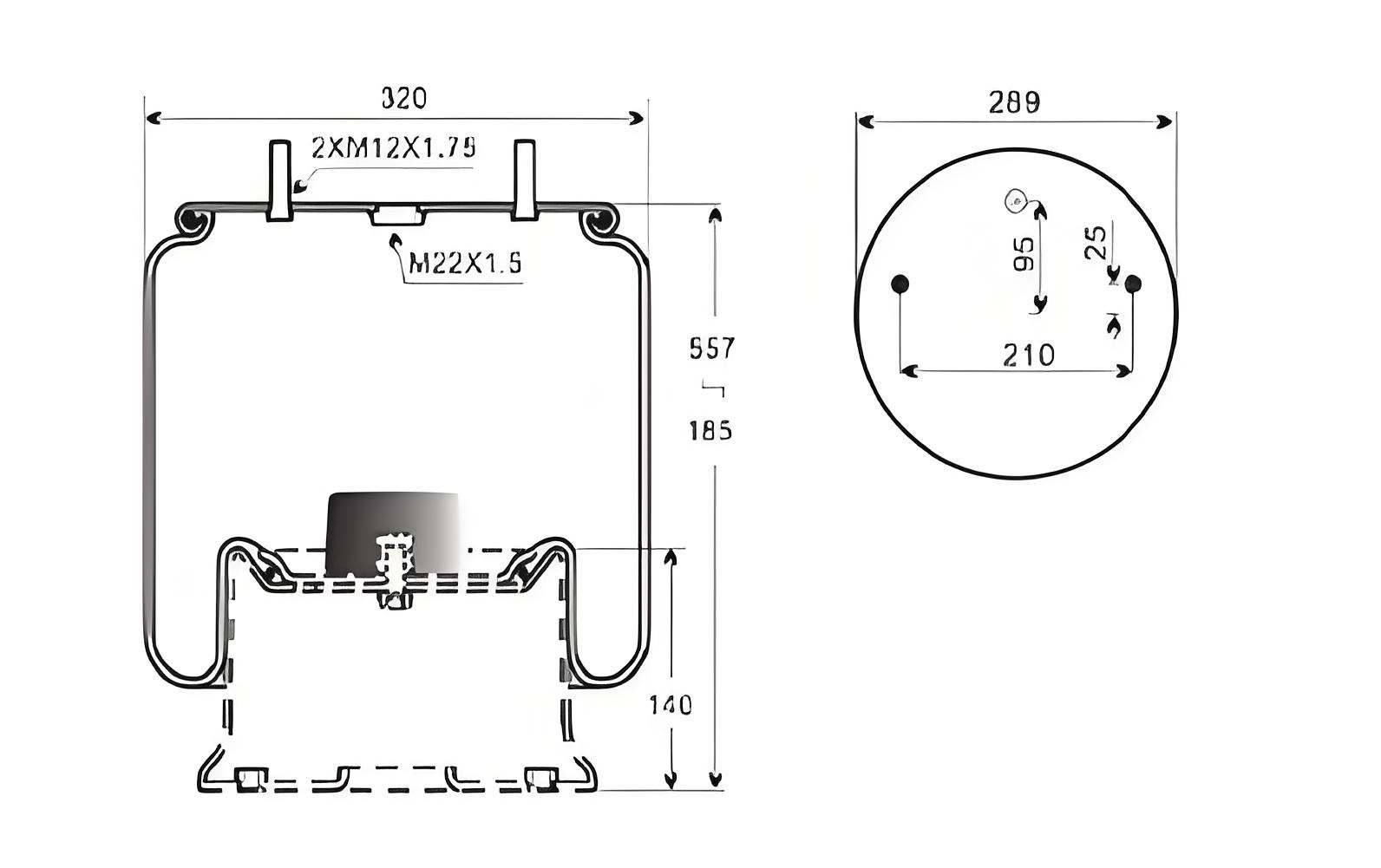

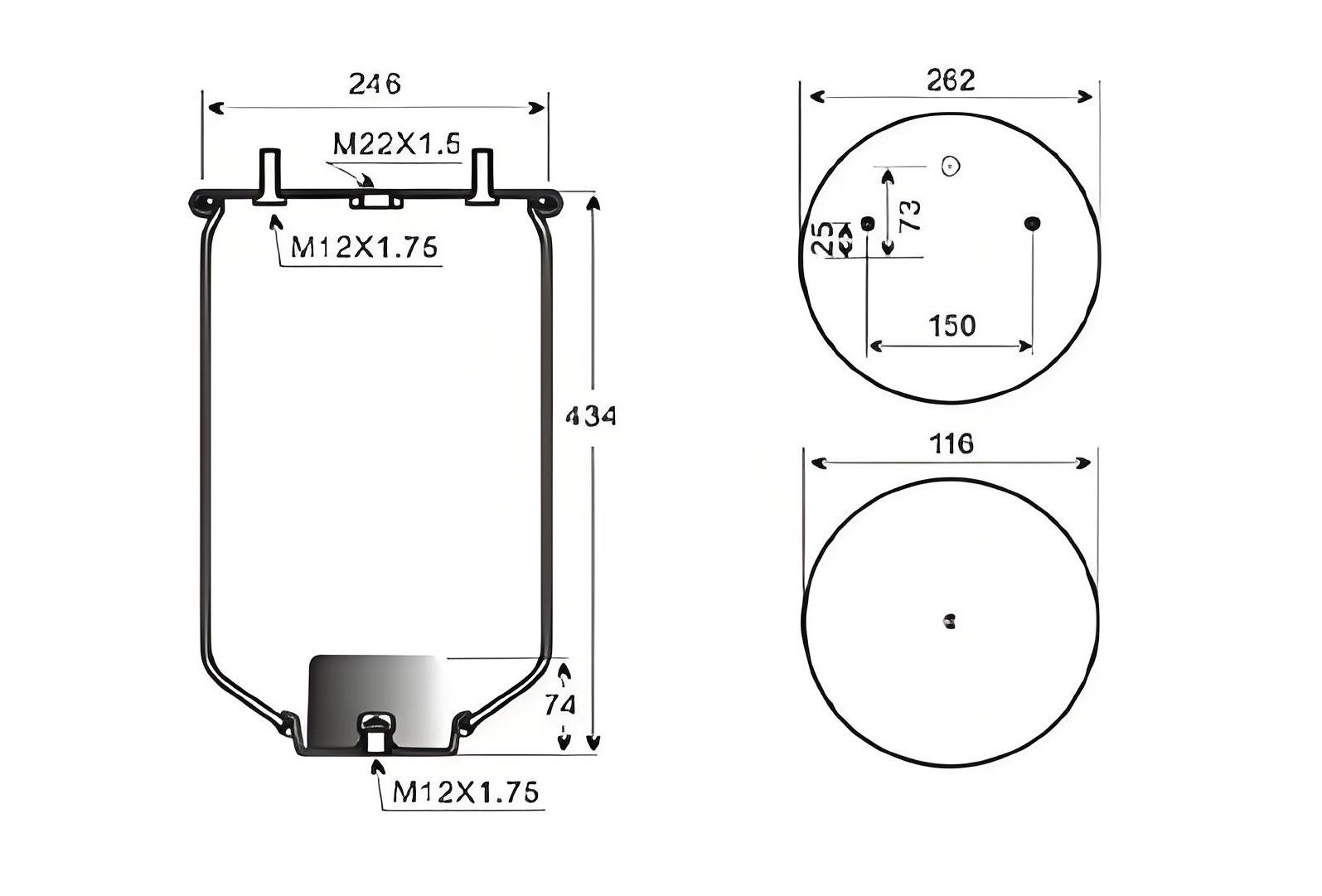

Model:1V 6364 SA

Firestone: W01-M58-6364

Contitech: 813MB

Goodyear: 1R14-061

Phoenix: 1D28G-9121

Viberti: 128147

SAE: 8403/102

Trailor: 0036158E

Tec: 505858/01

Weweler: US07345

E.R.F. Truck: 143908-3

SAF: 3.229.0003.00

Hendrickson: 505859

ROR/Meritor: 21215633

RVI: 5.000.790.692

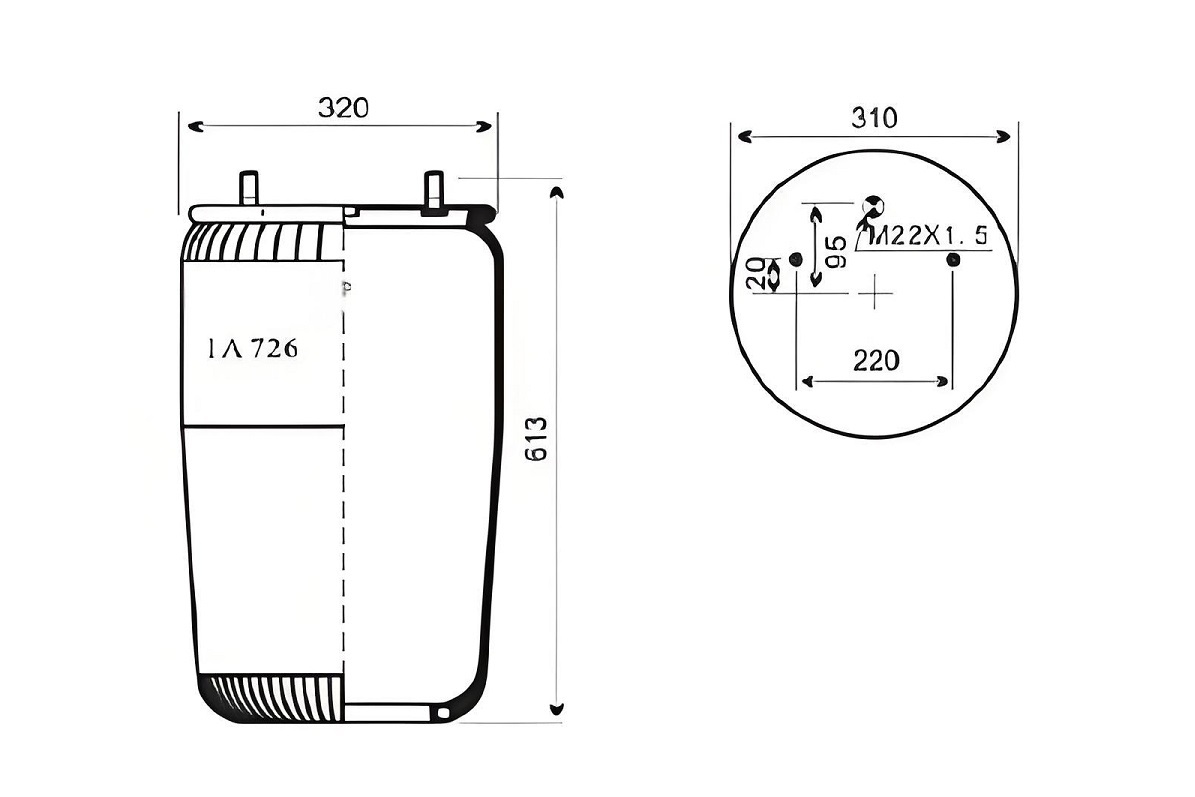

Model:1V 7261 SA

Contitech: 726NP01

Gigant: 246192

Peautomotive: 040.086-00A

Peautomotive: 084.021-11A

Airsprings Book: 34762-S

Model:1V 6338 SA

Firestone: W01-M58-6338 / 1T19L-7

Contitech: 4810NP05 / 61162

Goodyear: 1R14-730

Phoenix: 1D28A10

Taurus: KR621-18

Dunlop FR: D13B25

Peautomotive: 1T19E-1 / 205456

Airtech: 133422 / 32918K

Granning: 16092 / 133422 / 32918K

WABCO: 9518147300

SAF: 3.229.0027.00 / 2918V

SAF: 3.229.0027.00

Meritor: MLF7025

Model:1V 6251 SA

Model:1V 5870 SA

Contitech: 4757N2

Airtech: 34757-02K

Airfren: 20.1757.9CM

DT: 4.80857

Peautomotive: 084.111-13A

Peautomotive: 084.111-73A

Templin: 04.010.6100.221

DB Truck: 9743280101

Mercedes BENZ: A9743280001

Model:1V 6030 SA

Firestone: W01-M58-8474

Contitech: 6608NP01

Goodyear: 1R10-704

Phoenix: 1DF17B-1

Airtech: 132902 / 36416K

Airfren: 20.6608.1CM

Granning: 92500

DT: 2.62177

Templin: 04.020.6201.050

Templin: 04.060.6206.050

WABCO: 9518110020

Meritor: MLF7151

Volvo: 20582215 / 20531985

Volvo: 20456152 / 20374510

Volvo: 3171693 / 1076416

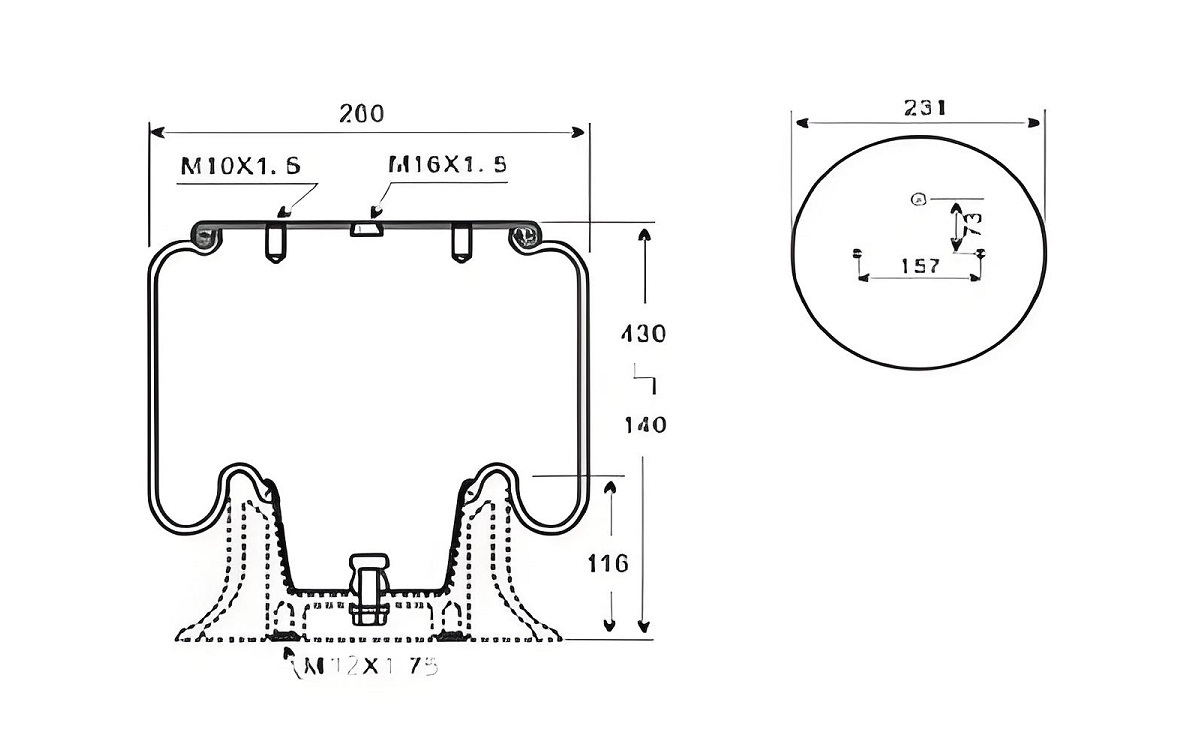

Model:1V 0756 SA

Firestone: W01-M58-0756 / 1T17B-6

Contitech: 4022NP02

Goodyear: 1R11-709 / 1DK22EP (NP)

Dunlop FR: D11U40 / D12A05

Airtech: 34022P

SAF: 3.229.0029.00

SAF Type: 2618V / 4.284.3006.00