Air Spring for Buses

AIRSPRINGO air spring systems offer over 500 product lines worldwide, covering almost all commonly used air spring models for trailers, trucks, and buses. The products are guaranteed to meet the highest quality standards while also complying with the specifications of vehicle manufacturers active in the aftermarket.————Air Spring for Trailer Axles are components used in the suspension system of trailers to provide cushioning and support. They help absorb shocks and vibrations from the road, ensuring a smoother ride and improving stability. These air springs allow for adjustable load capacities, enhancing the performance of trailers under varying conditions. They are commonly used in heavy-duty trailers, ensuring better weight distribution, reduced wear on other suspension components, and improved overall vehicle handling.

Air Spring for Buses

Frequently Asked Questions

What are the benefits of using Air Spring for Buses?

Using air springs for buses offers several key benefits, improving both the performance of the vehicle and the comfort of passengers. Here are the primary advantages:

1. Improved Ride Comfort

Air springs provide a smoother and more comfortable ride by absorbing shocks and vibrations from the road. This helps to reduce the impact of bumps and uneven surfaces, enhancing passenger comfort, especially on long journeys.

2. Better Load Distribution

Air springs are adjustable, meaning they can maintain an even distribution of weight across the vehicle. This helps to balance the load, preventing excessive wear on any particular part of the suspension system and ensuring a more stable ride.

3. Enhanced Safety

Air springs improve the stability of the bus, especially in adverse road conditions. They help maintain the correct ride height, reducing the risk of tipping or instability during sharp turns or when the vehicle is loaded unevenly.

4. Durability and Longevity

Air springs are highly durable and designed to withstand the stresses of heavy-duty operations, including the weight of passengers and luggage. They are less likely to suffer from wear and tear compared to traditional metal springs, providing a longer service life and reducing maintenance costs.

5. Adjustable Suspension for Different Conditions

The air spring system can be adjusted to suit different road conditions or load capacities. This adaptability ensures that buses maintain an optimal suspension setting whether they are empty or fully loaded, resulting in better handling and comfort at all times.

6. Noise and Vibration Reduction

Air springs significantly reduce the noise and vibrations transmitted through the bus structure, resulting in a quieter cabin environment. This is especially beneficial for the comfort of passengers, as well as for reducing noise pollution in urban environments.

7. Increased Fuel Efficiency

Air suspension systems are lighter than traditional steel spring systems, which can help improve fuel efficiency. By reducing the overall weight of the vehicle, air springs contribute to lower fuel consumption over time.

8. Lower Maintenance Costs

Due to their design and durability, air springs typically require less maintenance compared to traditional suspension systems. With fewer moving parts and a more resilient structure, the need for repairs and replacements is reduced, leading to lower long-term operational costs.

9. Improved Handling and Maneuverability

Air springs provide more precise control over the bus’s suspension, improving handling, especially in tight turns or while navigating obstacles. This gives bus drivers better control, contributing to smoother and safer driving.

10. Passenger Experience

Overall, air springs contribute to a more pleasant journey for passengers. The reduction in bumps, vibrations, and noise improves the overall travel experience, especially for long-distance passengers.

Conclusion

Air springs enhance the performance, comfort, safety, and longevity of buses. By offering a smooth, adjustable suspension system, air springs ensure that buses provide a better experience for both passengers and drivers, while also reducing long-term costs for bus operators.

How Does the air spring for buses Function?

- Adjustable Suspension: Allows the bus to adapt to different loads and driving conditions by adjusting air pressure in the airbags.

- Shock Absorption: Provides a smoother ride by absorbing shocks from the road, reducing vibrations and noise.

- Ride Height Maintenance: Keeps the bus level and stable, even under varying loads, ensuring optimal handling and safety.

- Automatic Adjustment: Sensors and compressors automatically adjust air pressure to maintain the ideal suspension settings.

- Enhanced Handling: Improves the bus’s handling and stability, especially during turns and on rough roads.

In conclusion, the air spring system enhances both the performance and comfort of the bus, providing a smooth, stable, and adaptable suspension solution that responds dynamically to changing conditions, improving both safety and passenger experience.

What are the applications of the air spring buses?

Air springs in buses are widely used across various applications to improve ride quality, stability, safety, and operational efficiency. These applications span from urban transit buses to long-distance coaches and specialty vehicles, where air springs help optimize the vehicle’s suspension system to meet the demands of different environments and load conditions. Below are the main applications of air springs in buses:

1. Urban Transit Buses (City Buses)

- Purpose: Air springs in city buses are primarily used to provide a smoother and more comfortable ride for passengers while navigating through the busy streets, frequent stops, and uneven road surfaces.

- Benefits:

- Improved Ride Comfort: They absorb shocks and vibrations from potholes, speed bumps, and uneven roads, ensuring a more pleasant ride for passengers.

- Passenger Comfort: Reduces body roll and vehicle bouncing during sharp turns and stop-and-go driving, which is typical in urban environments.

- Low Floor Design: Air springs help maintain a consistent ride height, which is essential for low-floor buses that allow easy boarding and disembarking for passengers, including those with disabilities.

2. Intercity Buses (Coach Buses)

- Purpose: Air springs are commonly used in long-distance intercity buses (also called coaches) to enhance the comfort of passengers on long trips, where road conditions can vary from smooth highways to bumpy country roads.

- Benefits:

- Enhanced Comfort: Long-distance travel requires comfort for passengers, and air springs effectively cushion the impact of road imperfections, minimizing passenger discomfort over extended travel times.

- Stability: Air springs provide superior stability, particularly in the case of fully-loaded buses, ensuring that the vehicle remains level even with fluctuating passenger numbers or luggage.

- Reduced Road Noise: Air springs reduce noise and vibration transmission through the bus structure, creating a quieter and more pleasant travel environment.

3. Double-Decker Buses

- Purpose: In double-decker buses, air springs are used to provide optimal suspension to support the additional weight from the upper deck while maintaining passenger comfort and safety.

- Benefits:

- Weight Distribution: Double-decker buses can be top-heavy, and air springs help distribute the load evenly, ensuring a stable and balanced vehicle.

- Enhanced Stability: Air springs reduce body roll and sway, especially when navigating sharp corners or uneven roads, enhancing the overall handling of the bus.

- Comfort for Upper Deck Passengers: Air springs smooth out the ride for passengers on the top deck, who might otherwise experience more discomfort due to the bus’s higher center of gravity.

4. Tourist Buses

- Purpose: Air springs in tourist buses (or sightseeing buses) are used to provide a smooth and comfortable ride during city tours, sightseeing, or trips to various tourist destinations.

- Benefits:

- Passenger Experience: Tourist buses often travel on scenic but bumpy routes, and air springs ensure that passengers can enjoy the journey without being disturbed by road imperfections.

- Stability on Slopes: Many tourist destinations are on hilly or uneven terrain. Air springs help stabilize the bus, especially on inclines, by automatically adjusting the suspension to the load.

- Adjustable Ride: Air springs allow for adjustments to the suspension based on the number of passengers or the amount of luggage, maintaining an optimal ride height and comfort.

5. Airport Shuttle Buses

- Purpose: Airport shuttle buses, which transport passengers between terminals, parking lots, and airport hotels, benefit from air springs that help provide a smooth ride even under frequent stops and starts.

- Benefits:

- Frequent Stops: Air springs ensure that the bus maintains a stable ride despite frequent loading and unloading of passengers, which can alter the weight distribution.

- Comfort in Tight Spaces: Airport shuttle buses often navigate tight parking lots or crowded areas, where air springs can help improve the vehicle’s maneuverability and handling.

- Heavy Loads: These buses often carry large amounts of luggage, and air springs help manage the added weight, ensuring that the suspension remains level and provides a smooth ride.

6. School Buses

- Purpose: Although less common than in other types of buses, air springs are sometimes used in school buses to provide better comfort and support for students during their daily commutes.

- Benefits:

- Improved Comfort for Children: Air springs reduce the jarring effects of rough roads, offering a smoother ride for young passengers.

- Enhanced Safety: Air springs help maintain a stable and level ride, ensuring that the bus remains safe and balanced when fully loaded with children.

- Adaptable Suspension: Air springs provide the flexibility to adjust suspension settings based on the number of students or their seating arrangements.

7. Heavy-Duty and Specialty Buses (e.g., Military, Airport Service)

- Purpose: Air springs are also used in heavy-duty and specialty buses, such as those used in military, airport service, and other industrial applications where the bus needs to handle large loads and operate in harsh environments.

- Benefits:

- Durability and Performance: In military or airport service, buses are often required to operate in tough conditions with heavy loads. Air springs offer durability and ensure that the vehicle can handle significant weight while maintaining a comfortable ride.

- Maneuverability: Air springs enhance the handling and stability of specialty buses, improving maneuverability in tight spaces or rough terrain.

- Load Adaptability: These buses often carry varying loads (e.g., equipment, personnel), and the air suspension system adjusts automatically to ensure optimal performance.

8. Electric Buses

- Purpose: Air springs in electric buses provide the same benefits as in traditional diesel-powered buses, but they are especially valuable for electric buses, which are often designed for high efficiency and passenger comfort.

- Benefits:

- Improved Energy Efficiency: Air springs reduce mechanical wear, which can help electric buses maintain higher levels of efficiency and reduce energy consumption.

- Low-Noise Operation: As electric buses are already quieter than traditional buses, air springs further reduce noise and vibration, contributing to a quieter, more comfortable environment.

- Enhanced Stability: With the heavy batteries placed at the base of electric buses, air springs help distribute the weight and stabilize the vehicle’s handling.

9. Articulated Buses

- Purpose: Articulated buses (or “bendies”) are long buses with a flexible joint, often used in high-capacity public transportation. Air springs provide enhanced suspension for these vehicles, which have a more complex structure due to the pivot point in the middle.

- Benefits:

- Improved Maneuverability: Air springs help improve the stability and handling of articulated buses, especially when making turns or negotiating tight spaces.

- Reduced Wear on Articulation Joint: By providing a smoother and more controlled ride, air springs reduce the stress on the articulation joint and prolong the life of the vehicle.

- Load Compensation: As articulated buses can carry more passengers, air springs help adjust the suspension to accommodate the increased weight without compromising stability or comfort.

Do Not Exceed the Recommended Safe Extended Height: When installing or using an air spring, ensure that it is not extended beyond the recommended height. Exceeding this height could lead to excessive strain on the air spring, resulting in damage or reduced performance over time. Always follow the manufacturer’s guidelines regarding the safe extended height for proper operation.

Avoid Using Below the Minimum Compressed Height: To prolong the lifespan of the air spring, it is crucial not to operate it below its minimum compressed height. Operating below this threshold can cause the rubber bladder to become overstretched, leading to premature wear and potential failure. Ensure the air spring is within the correct compression range during use.

Do Not Use at a Pressure Exceeding 0.7 MPa: The air spring must be operated within the specified pressure limits to maintain optimal performance and safety. Exceeding a pressure of 0.7 MPa could lead to over-stretching of the air spring, compromising its structural integrity. Always check and regulate the air pressure according to the manufacturer’s recommendations.

Avoid Twisting the Air Spring: During installation and use, it is important to avoid twisting the air spring. A twisted air spring can lead to uneven distribution of air pressure, causing internal damage or even failure. Make sure the air spring is installed in a straight and aligned position to ensure proper function and durability.

- The air spring for trailer axles are typically available in stock.

- The air springs manufactured by Shanghai Songjiang meet national standards and come with a one-year warranty. Any quality issues can be exchanged within this period.

- There is no purchase quantity limit. Small orders are generally shipped via international couriers such as DHL, FEDEX, UPS, TNT, etc., ensuring fast delivery, usually within 3-7 business days.

Air Spring for Buses Model List:

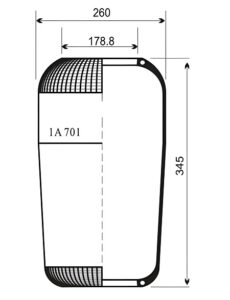

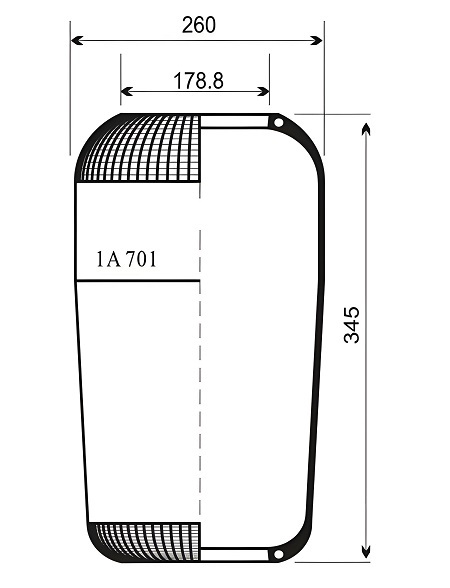

Model:1A 701

Firestone : W01-095-0205 / 1R3M340340

Contitech : 701N

Goodyear : 9006

Phoenix : 1E26-1

Taurus : N116-1

Ikarus : B510040

Bova : B510040

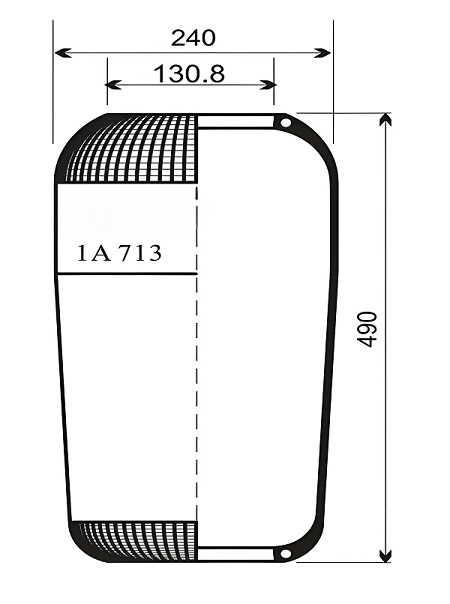

Model:1A 713

Firestone:N/A

Contitiech:713N

Goodyear:9066

Phoenix:1F21D

Volvo:1622116 / 6797169

Model:1A 737

Firestone:W01-095-0211 / 1R1A-480-330

Contitech:737N

Goodyear:9075

Phoenix:1F26

Taurus:B127

CF Gomma :1S323-23

Airtech:3737(A520027)

EVECO:4746740

Menarini:178739

BENZ:393.328.0101

SAF: 3.229.0003.00

Hendrickson: 505859

ROR/Meritor: 21215633

RVI: 5.000.790.692

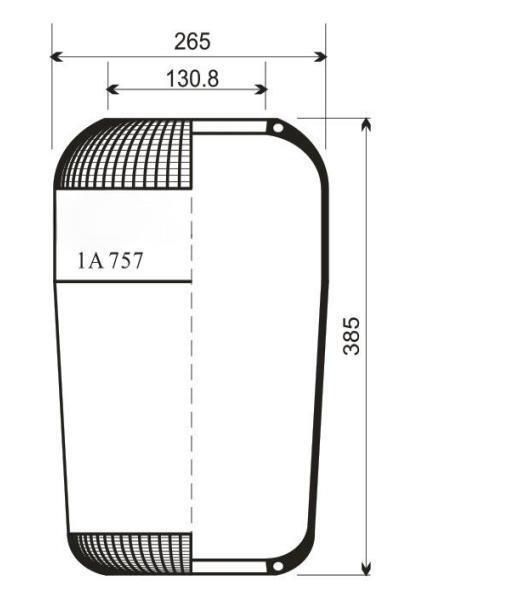

Model:1A 757

Firestone:W01-095-0212/1R2A380305

Contitech:757N

Goodyear:9077

Phoenix:1F26C

Taurus:B126

BENZ:363.328.0201

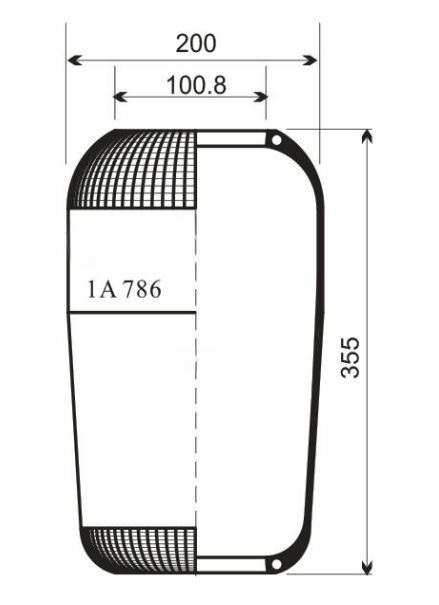

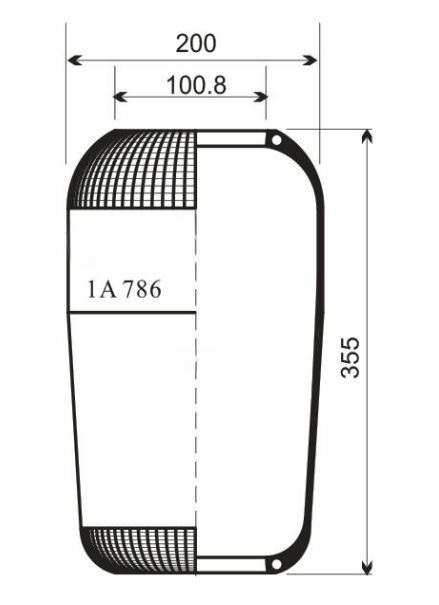

Model:1A 786

Firestone:W01-095-0436/1R2S355245

Contitech:786N

Goodyear:N/A

Phoenix:1F14

MAN:81.43601.0053

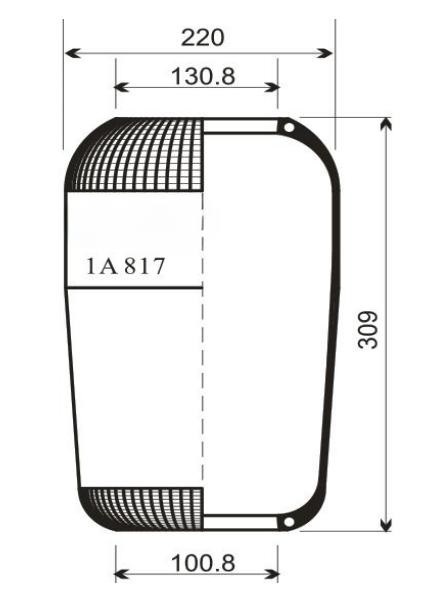

Model:1A 817

Contitech:817N

CF Gomma :97326 / 1SC240-30BB

Airtech:8038171

Bredamenarini Bus:252933

RVI:5.000.805.998/5.810.111.355

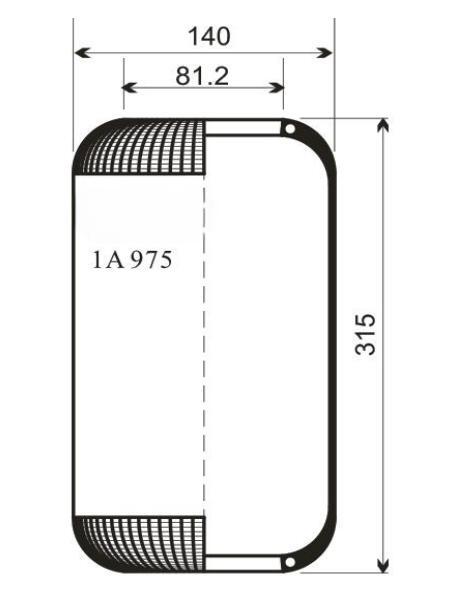

Model:1A 975

Firestone:W01-095-0437/1R1T320195

Contitech:975N

Phoenix:1E10

Airtech:3975

Granning:15637

ZF:0501312548

EVO(DC):A6993280101

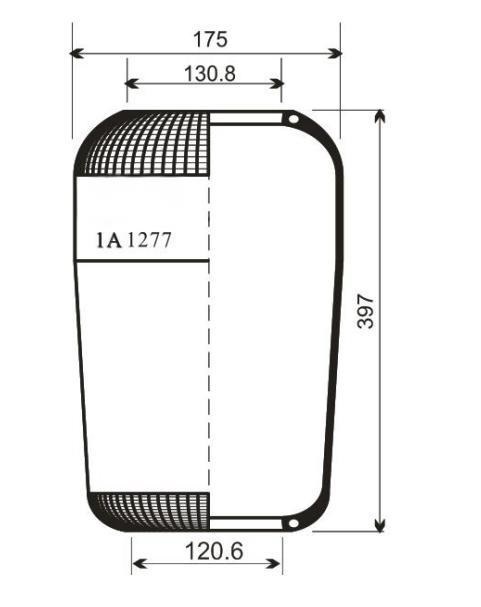

Model:1A 1277

Firestone:W01-095-0453/1R4U395260

Dunlop Uk:A310950013

Airtech:31277/111302

Granning:16166

Volvo Buss:3111277

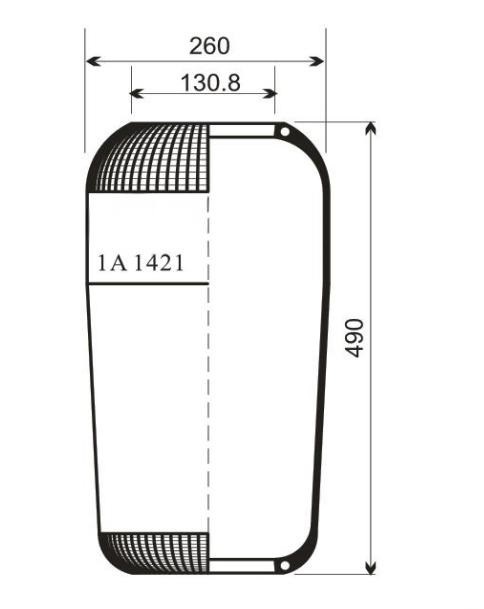

Model:1A 1421

Firestone:W01-095-0472/1R2A490305

Contitech:1421N

Airtech:31421/111482

Volvo:1075290/1593842/1622122/1622115/268042100

WABCO:8961301934

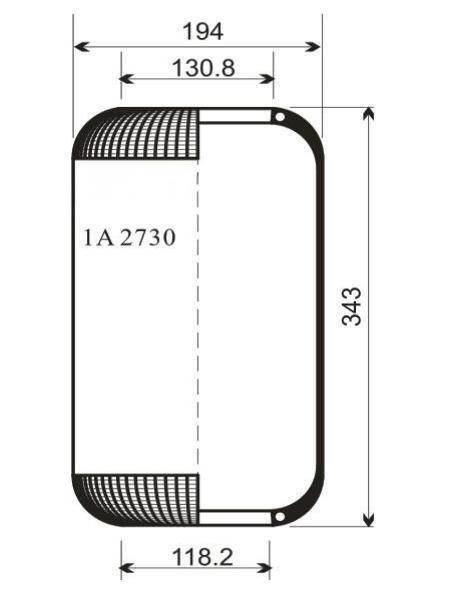

Model:1A 2730

Airtech:30792

TEMPLIN:04.020.6201.140

Volvo B6R:20540792

DT:2.62435

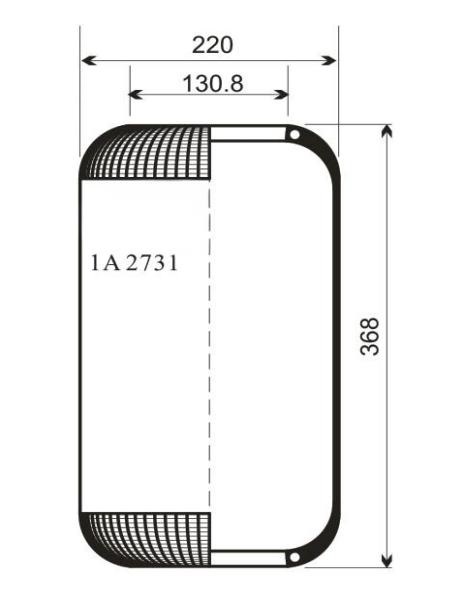

Model:1A 2731

Goodyear:9081

Volvo B6R:20540789

TEMPLIN:04.020.6201.150

AIRTECH:30789

DT:2.62436

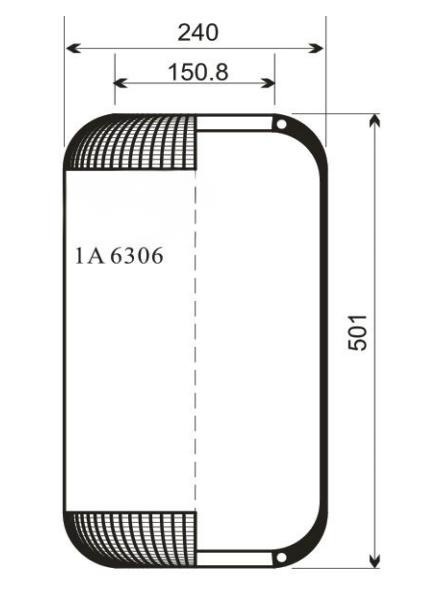

Model:1A 6306

CF Gomma :1S323-36 / 203833

Goodyear:8314

Ievco:41022620

Pirelli:1S323-36

AIRTECH:336323

TEMPLIN:04.040.0003.160

AIRFREN:20.0876.G

KAISER:MLF8199