How to Choose the Right Vibration Isolator for Suspended Equipment?

Is your suspended equipment causing unexpected vibration and noise problems? You’re not alone. Many struggle with HVAC systems or ceiling-mounted units that disrupt peace and performance. But choosing the right spring vibration isolators HVAC can fix this.

To choose the right vibration isolator for suspended equipment, follow a vibration isolator selection guide that considers load, natural frequency, installation type, and environment. Use vibration isolator calculation tools to match specifications accurately.

Let’s dive into the critical factors and avoidable mistakes in isolator selection.

Why Do Suspended Equipment Require Vibration Isolators?

Suspended systems like AHUs, FCUs, or duct-mounted fans generate vibrations that travel through the building structure.

Without proper isolation, these vibrations can lead to noise complaints, reduced equipment lifespan, and even structural fatigue.

Vibration isolators help break this transmission path. They protect both equipment and occupants from harmful resonance and airborne or structure-borne noise. In HVAC applications especially, their role is essential to maintain comfort and performance.

What Factors Should You Consider When Selecting an Isolator?

Selecting the wrong isolator can do more harm than good. You need a comprehensive vibration isolator selection guide to get it right.

Key factors include:

-

Load Capacity: Match isolator capacity with equipment weight.

-

Natural Frequency: Ensure it differs significantly from the equipment’s operating frequency.

-

Mounting Configuration: Horizontal vs. vertical installation affects isolator choice.

-

Environment: Moisture, dust, and corrosion risks impact vibration isolator specification.

-

Deflection: The amount of movement under load plays a key role in isolation efficiency.

Using isolator selection calculation methods ensures your selection is not just theoretical but practically effective.

Are Spring Isolators Suitable for Suspended Equipment?

Yes—especially in HVAC systems where vibration levels are moderate to high.

Spring vibration isolators HVAC offer excellent low-frequency isolation, making them ideal for air handling units and large fans.

However, correct sizing is crucial. Too stiff a spring reduces effectiveness, while too soft risks instability. Always verify spring stiffness, damping ratios, and vibration isolator deflection to ensure compatibility.

When Are Rubber-Type Isolators a Better Choice?

Rubber isolators are ideal for lighter equipment and less demanding applications.

They are compact, cost-effective, and provide decent isolation for ceiling-mounted speakers, small fans, or control boxes.

Rubber types also have built-in damping, which reduces resonant peaks. However, they’re less effective at isolating low-frequency vibrations compared to spring-based solutions.

What Does “Deflection” Mean in Vibration Isolation?

Vibration isolator deflection refers to the movement an isolator undergoes under equipment load.

Greater deflection typically means better low-frequency isolation—but also larger displacement space.

You can use vibration isolator calculation tools to determine the required deflection that ensures the system’s natural frequency is far from the source vibration frequency, achieving effective isolation.

How to Evaluate an Isolator’s Performance?

You can refer to industry standards like the ASHRAE vibration isolation table, which helps assess required isolation efficiency based on equipment type and location.

Other performance metrics include:

-

Static deflection

-

Damping coefficient

-

Maximum load capacity

-

Material fatigue resistance

These parameters help confirm the vibration isolator specification meets real-world operating conditions.

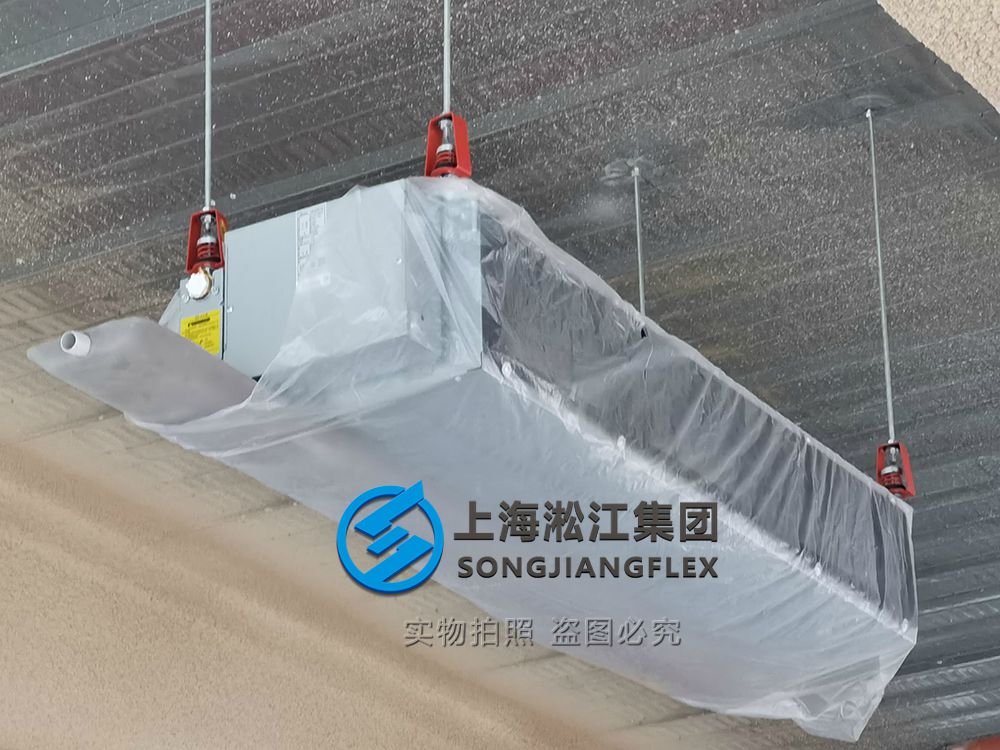

What Types of Isolators Are Commonly Used for Suspended Equipment?

Suspended vibration isolators come in different types to suit specific needs:

-

Spring hangers: Excellent for HVAC and duct systems

-

Rubber hangers: Good for light, compact installations

-

Hybrid or combination hangers: Offer both spring and damping for improved isolation

-

For floor-mounted systems under suspended platforms, consider spring floor mount vibration isolator options

Each type has specific mounting guidelines and usage conditions, so refer to an isolator manual or consult engineers when in doubt.

What Mistakes Should Be Avoided When Choosing Isolators?

Avoid these common pitfalls:

-

Ignoring operating frequency and choosing incorrect stiffness

-

Over-sizing the isolator, leading to poor performance

-

Installing without proper orientation or spacing

-

Selecting based only on price, not on performance

Missteps in selection and installation often lead to system inefficiencies and increased long-term costs.

Why Should You Consult a Professional Manufacturer?

Even with a vibration isolator selection guide, every project is different.

Complex equipment, unique mounting positions, or high noise requirements require tailored solutions.

Professional manufacturers like airspringo provide technical consultation, isolator selection calculation, and even custom-engineered solutions—helping you avoid trial and error while maximizing performance.

Summary

Choosing the right vibration isolator specification for suspended equipment requires technical insight—get expert help and rely on proven specs for peace of mind and performance.