Why Are Air Springs Essential for High-Speed Latex Production Lines in Leading Factories?

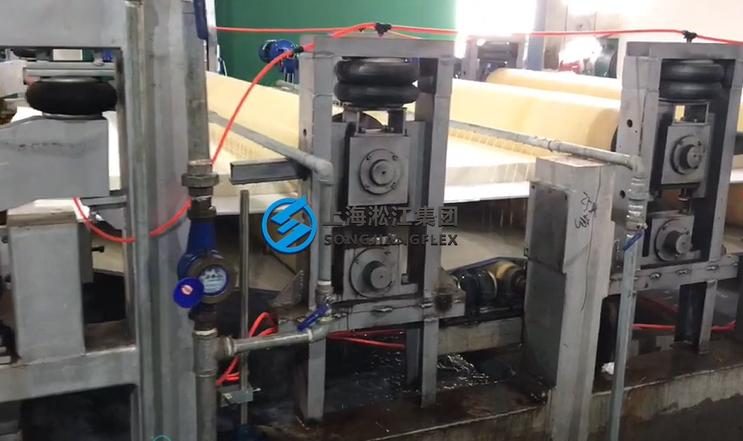

High-speed latex production lines often suffer from vibration issues, causing waste and equipment wear. Our air springs solve this with precise vibration isolation and noise reduction.

Air springs for latex production provide stable vibration isolation for latex glove manufacturing equipment and high-speed latex dipping line parts, improving efficiency, product quality, and extending machinery life.

Let’s explore how air springs enhance performance, protect equipment, and reduce costs on latex production lines.

1. How Do Air Springs Improve the Stability of Latex Production Lines?

High-speed latex machines can transmit vibrations across the production line, causing inconsistent thickness and surface defects in gloves and balloons.

Industrial air spring dampers isolate vibration effectively, ensuring production line stability and consistent product quality.

Air springs use adjustable air pressure to match equipment weight and speed, providing precise vibration control for latex industry machinery. This reduces machine stress, minimizes downtime, and ensures smooth operation across high-speed latex dipping line parts.

2. How Do Air Springs Improve the Efficiency of Latex Product Manufacturing Lines?

Manufacturing efficiency is crucial for profitability in latex production. Frequent downtime and vibration reduce output significantly.

Air springs reduce equipment stoppages and maintenance frequency, boosting production efficiency for latex glove manufacturing equipment and balloon lines.

By stabilizing machinery and lowering vibration-induced errors, air springs enable faster production cycles and higher yield rates. Factories can meet peak demand without compromising quality, making rubber air springs for factories an ideal solution.

3. What Role Do Air Springs Play in Reducing Vibration During Latex Processing?

Excessive vibration reduces mechanical precision and compromises product quality in latex processing.

Air suspension for latex processing absorbs and isolates vibrations, protecting both machines and end products.

Precision vibration control for latex industry ensures that gloves, balloons, and other latex products remain uniform. Industrial air spring dampers adjust dynamically to varying production speeds, maintaining consistent performance on high-speed latex dipping line parts.

4. Why Are Air Springs Better Than Metal Springs in Latex Product Equipment?

Metal springs can wear quickly and generate noise, limiting their effectiveness in high-speed latex machinery.

Rubber air springs for factories offer superior durability, noise reduction in latex manufacturing, and enhanced vibration isolation.

Compared to metal springs, air springs reduce mechanical stress, extend equipment lifespan, and minimize downtime. Customized air springs for industrial use also allow fine-tuning to specific latex production line requirements.

5. How Can Air Springs Extend the Service Life of Latex Production Machinery?

Latex production equipment is a significant investment, and prolonged lifespan lowers long-term costs.

Air springs absorb vibrations and shocks, protecting critical components and extending machinery life.

Key machinery like motors, pumps, and dipping machines benefit from reduced wear. Over time, vibration isolation for latex machines translates to fewer replacements, lower repair costs, and stable long-term operation.

6. What Are the Key Benefits of Using Air Springs in High-Speed Latex Dipping Machines?

High-speed dipping machines produce vibration, noise, and equipment stress.

Air springs provide precision vibration control for latex industry machinery, improving efficiency, minimizing defects, and extending operational life.

Using air springs for latex production lines ensures consistent glove thickness and smooth balloon surfaces. Factories experience higher throughput, lower waste rates, and reduced machine fatigue.

7. How Do Air Springs Help Maintain Product Quality in Latex Manufacturing?

Product quality is critical in competitive latex markets. Uneven surfaces and thickness variations reduce market acceptance.

Air springs stabilize production lines, ensuring uniform thickness and smooth surfaces for gloves and balloons.

By controlling vibrations, air springs minimize defects such as bubbles or irregularities. This precision vibration control for latex industry machinery leads to higher first-pass yield rates and improved customer satisfaction.

8. What Types of Air Springs Are Best for Latex Glove and Balloon Production Lines?

Different production lines require specific vibration isolation solutions.

Air springs for latex production can be customized with adjustable air pressure or specialized rubber compounds to match machinery demands.

Factories can choose air springs based on equipment load, speed, and operational environment. High-speed latex dipping line parts benefit from tailored solutions to maintain optimal vibration isolation and noise reduction.

9. How Do Customized Air Springs Reduce Maintenance Costs in Latex Factories?

Maintenance and downtime significantly affect production costs in latex factories.

Customized air springs for industrial use minimize equipment failures, lowering repair expenses and extending service intervals.

By tailoring air springs to factory-specific machinery and production speeds, factories reduce wear on critical components. This ensures consistent performance and lowers long-term maintenance budgets, making them an essential investment for latex production lines.

Air springs guarantee stable production, consistent product quality, and extended equipment life, making them essential for high-speed latex glove and balloon manufacturing lines.