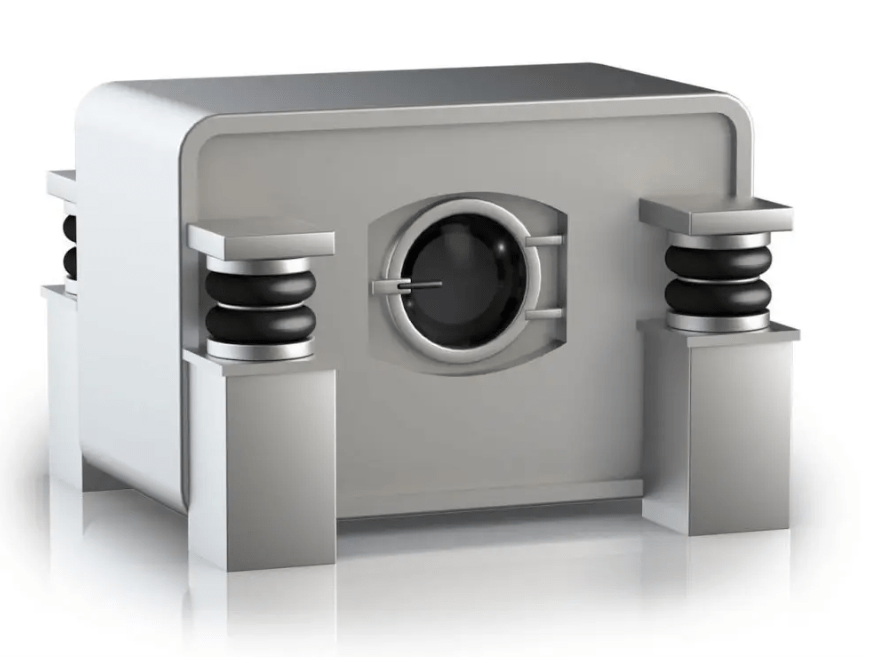

Air bellows located in compressors

Air springs are widely used in compressors to effectively reduce noise and vibrations during operation. By absorbing mechanical vibrations and pressure fluctuations, air springs enhance the stability of the equipment and extend the compressor’s service life. Additionally, they significantly improve the working environment by minimizing the impact of noise and vibrations on operators and nearby equipment.

Air bellows located in compressors

Applications and Uses of Air Springs in Compressors

Air springs are widely used in compressors, primarily to isolate vibrations generated during operation. They are particularly effective in reducing the impact of vibrations on equipment and the surrounding environment, especially during the operation of air conditioning systems.

Key Uses:

- Vibration Isolation: Air springs absorb and isolate mechanical vibrations transmitted during compressor operation, minimizing interference with other components and enhancing equipment stability.

- Shock Absorption: By adjusting the internal pressure of the air springs, their cushioning performance can be optimized to effectively absorb impact forces, protecting the internal structure of the compressor.

- Extended Lifespan: Reducing vibrations minimizes wear and tear on the compressor’s metal components, thereby extending its service life.

- Improved Environment: By decreasing vibration and noise, air springs create a better working environment, enhancing operator comfort and protecting surrounding equipment from damage.

With their flexible pressure adjustment capabilities, air springs are suitable for various loads and conditions, providing reliable support for the efficient and stable operation of compressors.

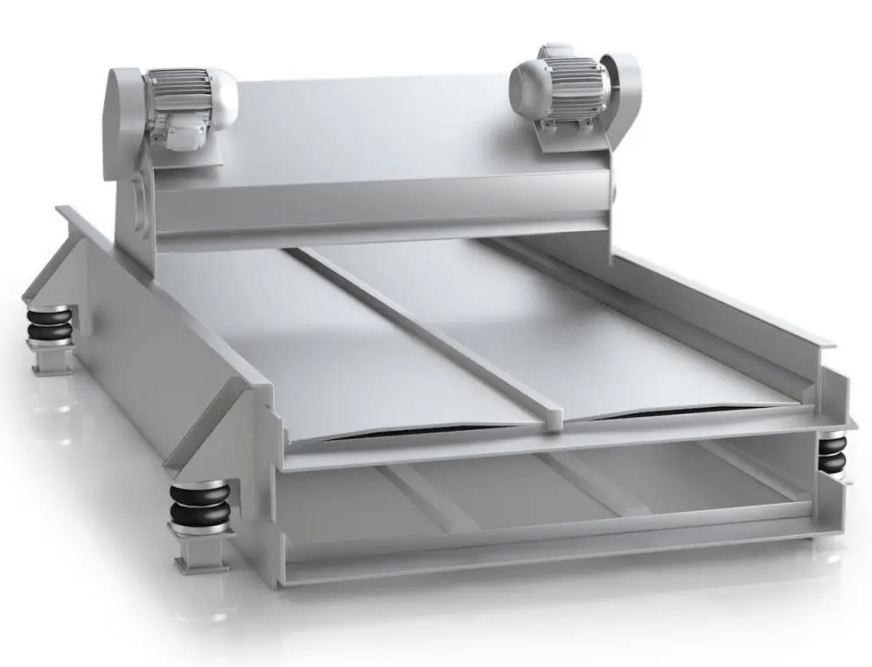

Blower and motor use air bellows

One of the main applications of the air bellows used here is to isolate the vibrations transmitted by the compressor during air conditioning operation. By using different types of air spring pressures, each air bellows can absorb the shocks and vibrations generated during the operation of the equipment.

Applications of air springs in other fields

- Rubber springs for food processing in vibrating tables

- Air springs used in the mining and construction field

- Convoluted bellow cylinder used in various production machines

- Air springs used in electric overhead traveling cranes

- Rubber air spring shock isolators in the Mining Industry

- Rubber air bellows used in bevelling machines

Get A Free Quotes