Rubber Bellows in Industrial Washing Machines

Rubber bellows play a crucial role in the operation of industrial washing machines, which are used in a variety of sectors such as manufacturing, food processing, and textiles. These machines often involve complex, high-speed mechanisms that require components capable of withstanding heavy use, exposure to water, detergents, and varying temperatures. Rubber bellows are employed to fulfill several important functions in these machines.

Industrial Rubber Bellows in Laundries

Application of Industrial Rubber Bellows in Laundries

Industrial rubber bellows are used in laundries to address the issues of vibrations, shocks, and noise generated by large industrial washing machines during operation.

Vibration and Shock Absorption

Large industrial washing machines generate strong vibrations and shocks during operation. These vibrations can cause damage to the equipment and disrupt the surrounding environment and other machinery. Industrial rubber bellows, as an elastic material, effectively absorb these vibrations and shocks, reducing their negative impact on the equipment and extending its lifespan. The flexible design of the bellows helps to absorb mechanical impacts caused by the operation of the machine, ensuring stable operation.Noise Control

Noise is another significant concern during the operation of industrial washing machines, especially during startup and shutdown. The high-speed and intense mechanical movements of the washing machine can create noise, which can be bothersome to operators. Rubber bellows have excellent noise absorption properties, which help to reduce the transmission of noise caused by vibrations. This not only minimizes discomfort for the operators but also improves the overall work environment.Suitability for Harsh Environments

Industrial rubber bellows are well-suited for harsh operating conditions. Industrial washing machines often operate in high-temperature, high-humidity environments, and rubber bellows, with their heat resistance and corrosion resistance, maintain good performance under these conditions. They prevent damage caused by high temperatures or washing liquids, ensuring the stability and safety of the machinery.Application Examples

In laundries, industrial rubber bellows are often installed at connection points or used in the machine’s vibration isolation system. They effectively reduce wear caused by vibrations without affecting the machine’s efficiency, and they minimize impact contact between equipment. Additionally, by reducing noise, they help create a quieter and more comfortable working environment, improving overall productivity.

In summary, the use of industrial rubber bellows in laundries addresses vibration, shock, and noise issues, improving the stability and safety of equipment while enhancing the operator’s working conditions.

The Role of Rubber Bellows as an Isolator

Rubber bellows, as an elastomeric material, are highly effective in addressing vibration, shock, and noise issues, making them an ideal solution for many industrial applications. In the case of industrial washing machines, rubber bellows can reduce up to 99% of the vibrations produced by the equipment during operation. This significant reduction in vibrations helps to minimize the impact on surrounding machinery and the structure of the building, preventing potential damage caused by excessive shaking.

In addition to vibration reduction, rubber bellows also help to minimize noise generated by the washing machine. By absorbing the vibrations, they prevent the transmission of noise to the surrounding environment, which is especially beneficial in maintaining a quieter working space for operators. Moreover, rubber bellows prevent vibrations from being transferred to the floor, reducing the risk of long-term damage to the building’s foundation.

One of the key advantages of using rubber bellows as an isolator is the protection they provide to the machine components. The rubber bellows suspension system absorbs the mechanical stress that would otherwise be transferred to the machine, effectively protecting its internal parts and extending its operational life. This leads to less wear and tear on critical components, which translates to fewer maintenance requirements and a longer service life for the equipment.

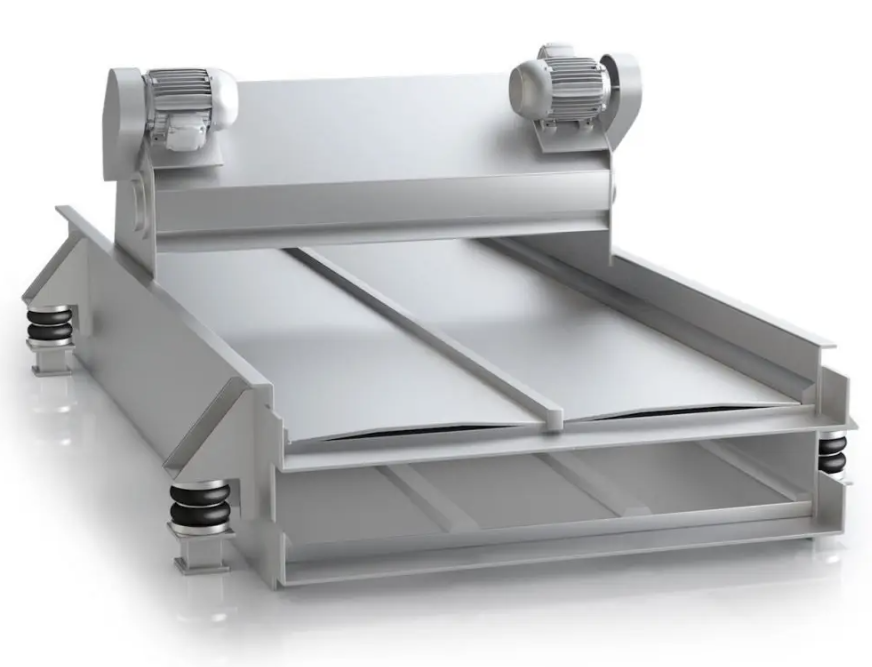

By analyzing the following picture, we can gain a clearer understanding of how rubber bellows function in this application and how they are installed. The visual representation will help clarify the installation process and the role of rubber bellows in isolating vibrations and shocks, offering a practical solution to the challenges faced by industrial washing machines.

The Rubber Bellow as a Dual-Function Component

While the rubber bellow is primarily known for its excellent vibration isolation properties, it is also capable of functioning as a pneumatic cylinder. This dual capability allows the rubber bellow to serve two distinct roles within the washing machine, combining vibration damping and pneumatic performance in one versatile component.

When the rubber bellows at the front of the washing machine contract, while those at the back expand, the washing machine can be tilted forward. This movement allows the operator to easily remove the cleaned laundry, making it much more convenient to access the inside of the machine. The flexibility of the rubber bellows helps achieve this tilt without compromising the stability of the machine. As a result, the process of unloading laundry becomes more efficient, with operators being able to quickly gather the clothes without unnecessary strain.

This design also provides significant ergonomic benefits. By enabling the machine to tilt forward, it reduces the need for operators to bend down excessively, allowing them to work in a more natural and comfortable position. This helps prevent physical strain and fatigue, improving overall productivity and the comfort of the personnel. Consequently, the process of removing the laundry from the washing machine becomes not only faster but also safer and more operator-friendly.

Advantages and Functions of Rubber Bellows in Washing Machines

As previously mentioned, the rubber bellow serves two key purposes in industrial washing machines:

- It functions as a rubber spring isolator to reduce vibrations.

- It acts as a rubber bellow actuator to facilitate the easy removal of laundry from inside the machine.

By combining these two functionalities, we can highlight the practical benefits of the rubber bellow.

Application of Rubber Bellows in Dryers

In industrial laundries, large dryers are used to remove moisture from washed clothes. These dryers often incorporate rubber bellow suspension systems, particularly the larger models, to absorb shocks and vibrations, thereby preventing damage or disruptions to the production process.

It is important to note that rubber bellow springs are commonly used in large industrial washing machines and dryers, which process large volumes of laundry on a daily basis.

Applications of air springs in other fields

- Rubber springs for food processing in vibrating tables

- Air springs used in the mining and construction field

- Convoluted bellow cylinder used in various production machines

- Air springs used in electric overhead traveling cranes

- Rubber air spring shock isolators in the Mining Industry

- Rubber air bellows used in bevelling machines

Get A Free Quotes