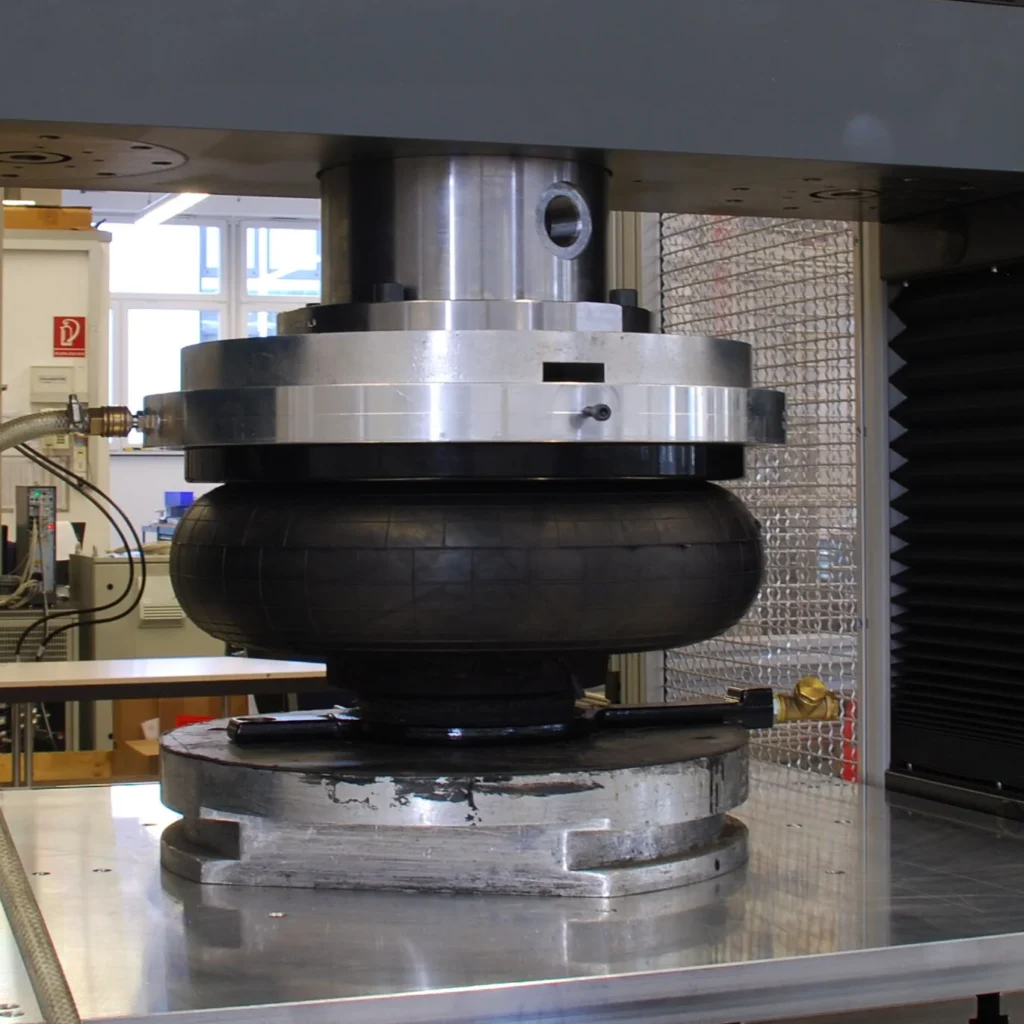

Pneumatic rubber bellows in delicate electronic equipment

Pneumatic rubber bellows are used in delicate electronic equipment to absorb vibrations and provide cushioning. They help protect sensitive components from shock and damage. Their flexibility ensures stable operation in various environments.

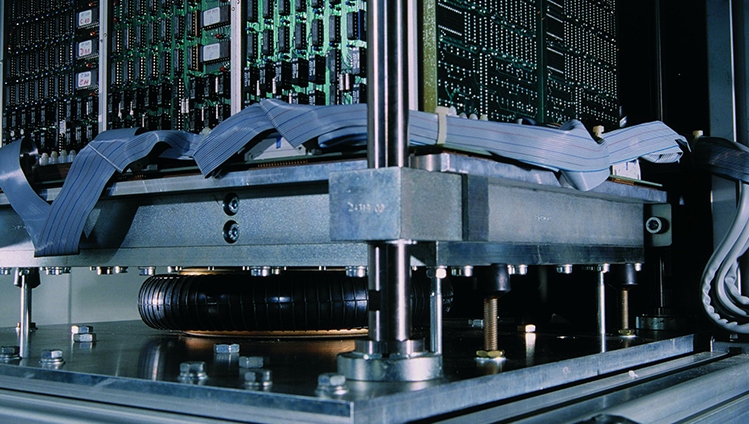

Air shock absorbers for laboratory use

Certain operations can only be conducted in specialized laboratory environments, where external disturbances, especially floor vibrations, must be minimized to the absolute minimum. Even the smallest vibrations can affect the precision of high-tech equipment during tests. Therefore, measures must be implemented to meet extremely high vibration requirements.

Air rubber or air shock absorbers can also be used in delicate laboratory electronic equipment and machinery. These devices are highly sensitive to vibrations, and any unwanted vibrations can affect their measurement accuracy. Common equipment includes analytical balances, hardness testers, spectrometers, microscopes, roughness testers, galvanometers, profile projectors, atomic force microscopes, roundness testers, electron microscopes, and atomic absorption spectrophotometers.

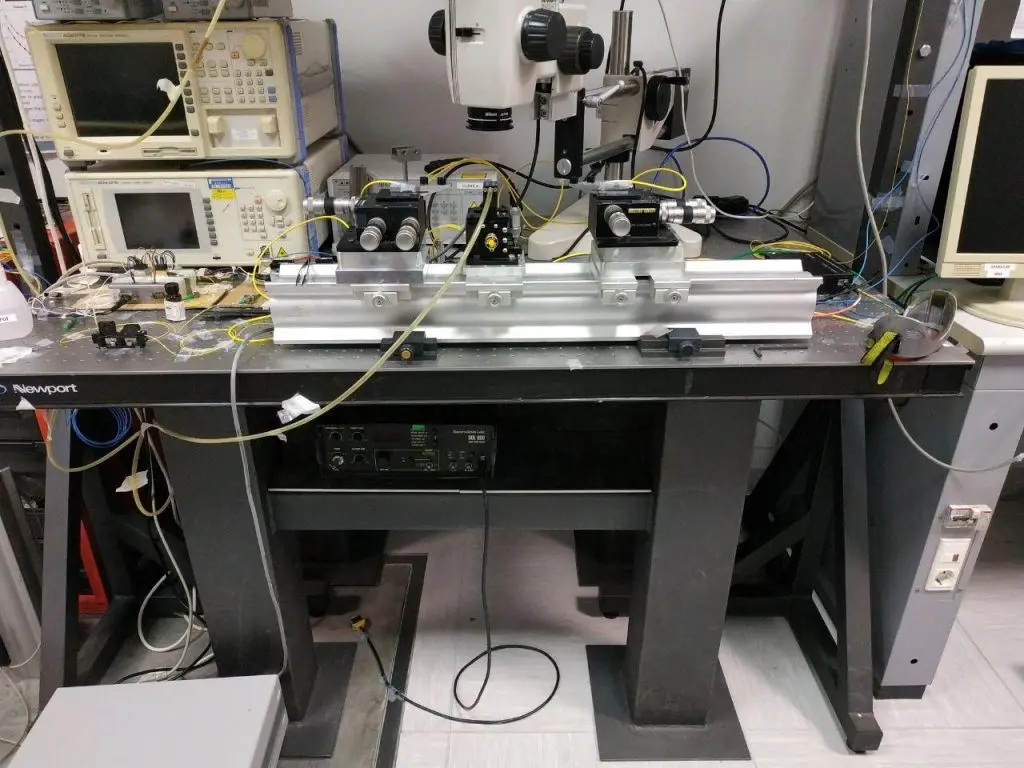

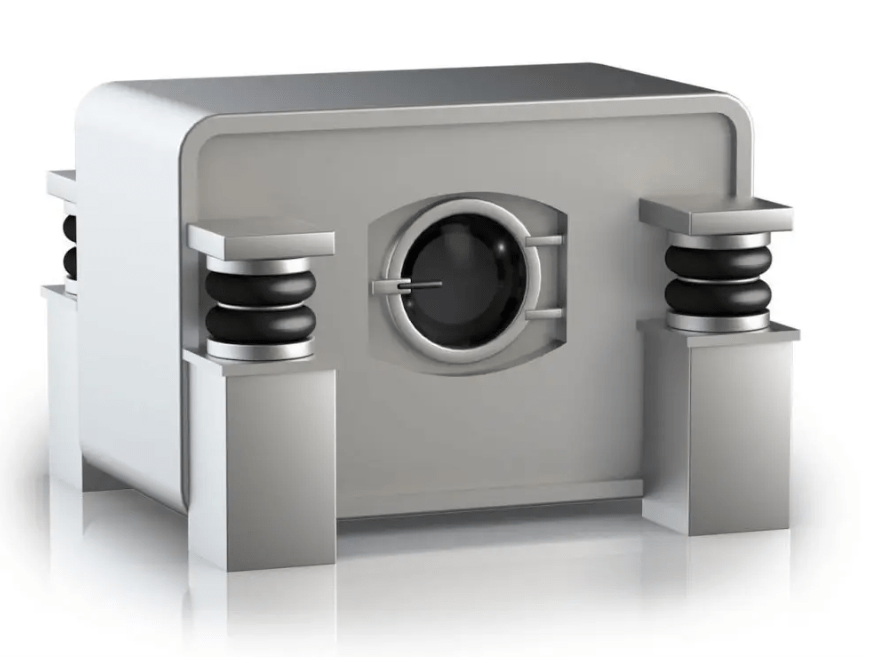

Optical instrument equipped with M-20 pneumatic rubber bellows

In the image above, we can see an optical device that requires extremely precise alignment to function properly. Due to the high sensitivity of the device, even the slightest vibration can affect its performance and accuracy. To mitigate this risk, M-20 pneumatic rubber bellows have been installed. These bellows help isolate the device from any external vibrations that might be caused by surrounding elements or equipment during the testing process. The importance of test accuracy in this case cannot be overstated, as even minor disturbances can lead to significant errors. By incorporating this vibration isolation solution, the optical device is protected, ensuring that the testing process is as precise and reliable as possible.

To prevent external disturbances, rubber bellows can serve as an effective solution. It is important to note that this type of shock absorber is not only suitable for conventional applications but can also be widely used in specialized environments, such as laboratories. The isolator effectively reduces the transmission of floor vibrations, preventing even the slightest tremors from affecting high-precision electronic equipment, especially the high-tech instruments used during experiments. These devices are extremely sensitive to vibrations, and even the smallest vibrations can lead to measurement discrepancies or damage to the equipment.

By utilizing rubber bellows and other shock absorption systems, the impact of external vibrations can be significantly reduced, thereby protecting the stability and accuracy of experimental equipment. Additionally, this vibration isolation measure enhances the accuracy of experiments and measurements. With vibration interference minimized, the experimental results become more reliable, reducing errors caused by vibrations and ensuring the precision of test data and the longevity of the equipment. This vibration control technology not only improves the overall performance of laboratory equipment but also extends the lifespan of the devices, lowering maintenance and replacement costs.

Applications of air springs in other fields

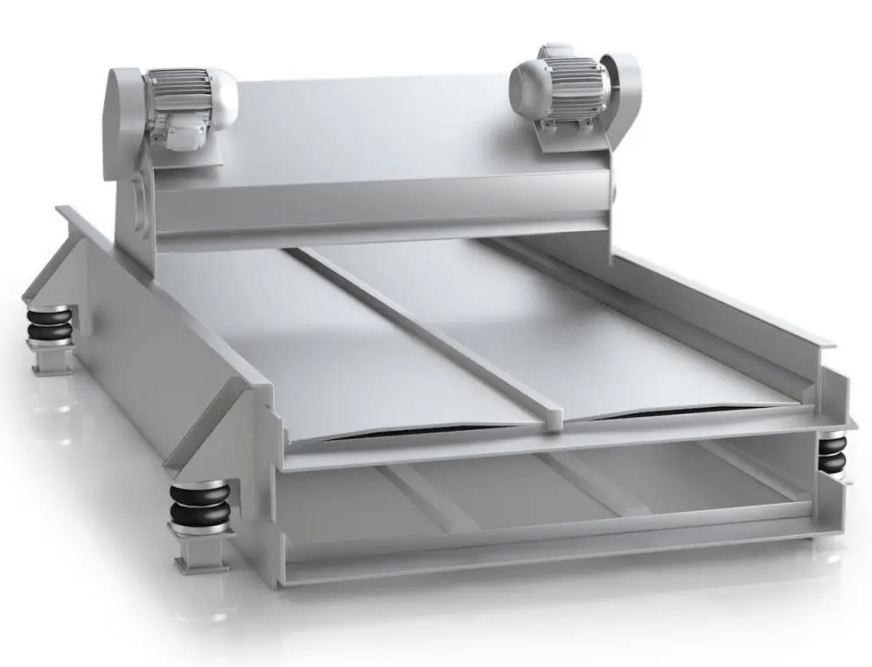

- Rubber springs for food processing in vibrating tables

- Air springs used in the mining and construction field

- Convoluted bellow cylinder used in various production machines

- Air springs used in electric overhead traveling cranes

- Rubber air spring shock isolators in the Mining Industry

- Rubber air bellows used in bevelling machines

Get A Free Quotes