Bellows Component in Belt Filter Systems

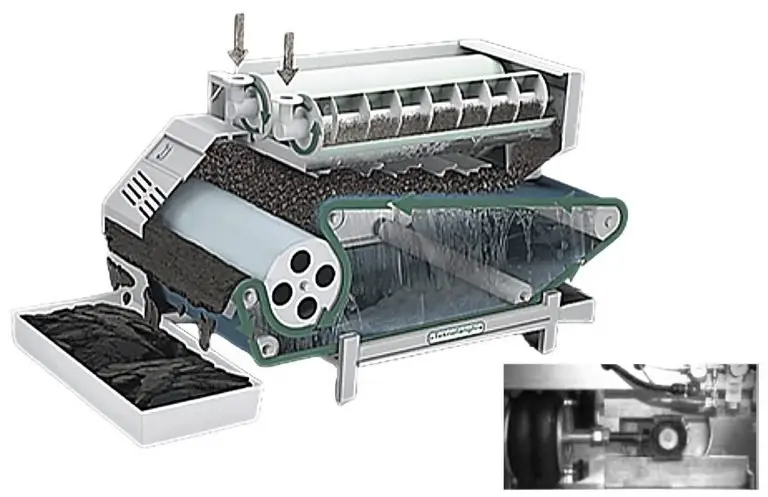

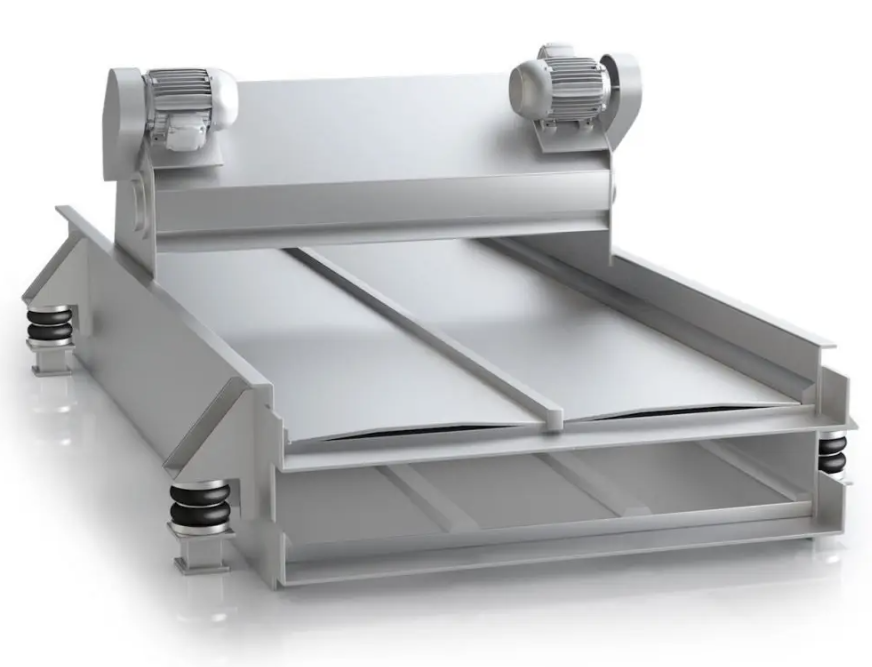

Bellow cylinders in belt filter systems are flexible components that help maintain proper tension and motion of the filtration belt. They allow for smooth operation by absorbing shocks and vibrations. These bellows are essential for enhancing the efficiency and durability of the filtration process.

Bellow Cylinders in Sludge Dewatering Key Role and Benefits

The bellow cylinder, as an actuator, is widely used in the sludge dewatering process in water treatment plants. Sludge dewatering is a crucial step in wastewater treatment, aimed at reducing the volume and weight of sludge for further handling and disposal. The bellow cylinder plays a key role in this process, functioning in several important ways:

Actuation Function: The bellow cylinder, typically made of flexible materials such as rubber or other elastomers, provides the necessary mechanical force to drive key components in dewatering equipment, such as the filter belt. It acts like a piston, converting pressure into mechanical motion, which compresses and releases the filtration belt periodically, effectively removing water from the sludge.

Shock Absorption and Buffering: The bellow cylinder absorbs shocks and vibrations in the system, ensuring stable operation of the dewatering equipment under heavy load. It helps reduce friction and wear, thus extending the lifespan of the equipment.

Efficiency Improvement: The elastic nature of the bellow cylinder allows it to adapt to varying pressure and load changes during operation, ensuring the equipment operates at optimal performance. This flexibility contributes to a more uniform and thorough water removal process, improving overall dewatering efficiency.

Corrosion Resistance and Durability: Given that the sludge dewatering process involves chemicals and moisture, bellow cylinders are often made from corrosion-resistant materials such as special rubbers or alloys to ensure long-lasting, stable performance in harsh environments.

In summary, the bellow cylinder, as an actuator, plays an irreplaceable role in the sludge dewatering process. It not only drives the operation of dewatering equipment effectively but also enhances system efficiency and durability through its shock-absorbing, corrosion-resistant, and flexible characteristics.

Role of Bellow Cylinders in Sludge Dewatering: Tension Control and Water-Sludge Separation

The function of the bellow cylinder is very similar to the air actuators used in paper machines or juice processing machines, and its working principle is widely applied in many industrial fields. In sludge dewatering systems, the bellow cylinder primarily regulates the tension of the transport belt (also known as the mesh belt), ensuring the stability and uniformity of the sludge during the filtration process. It adjusts its expansion and contraction through inflation and deflation, dynamically controlling the tension of the mesh belt and assisting in the separation of water and sludge.

Depending on the amount of sludge on the mesh belt, the bellow cylinder automatically expands or contracts. When the accumulation of sludge on the belt increases, the bellow cylinder expands to increase the tension on the mesh belt, ensuring that the sludge is adequately squeezed. Conversely, when the sludge amount decreases, the bellow cylinder contracts to prevent excessive tension that could affect the normal operation of the equipment. In this way, the bellow cylinder can self-adjust according to the actual operating conditions, ensuring the efficiency of the dewatering process.

At the same time, the bellow cylinder also plays an important role in controlling the flow of water and sludge. Through an accurate control system, the bellow cylinder not only adjusts the tension of the mesh belt but also effectively controls the rate of water flow, ensuring that the separation of water and sludge during the dewatering process is more uniform, thereby improving overall dewatering efficiency.

Bellow Cylinder vs Pneumatic Actuator

The bellow cylinder demonstrates exceptional performance, especially since it operates without the need for lubrication, allowing it to function reliably even when in a fixed position for extended periods. Unlike pneumatic actuators, which require lubrication, the elastomeric material of the bellow cylinder (typically made from high-performance rubber) does not require any oil, ensuring stable operation even during long periods of inactivity. This makes the bellow cylinder particularly reliable in applications that demand continuous, long-term performance.

In contrast, pneumatic actuators may encounter issues if left in a stationary position for too long. Since pneumatic actuators rely on compressed air and lubrication, prolonged inactivity can allow moisture to enter the system, potentially degrading the lubricant or causing a lack of it, which can impair the actuator’s functionality. Additionally, pneumatic actuators require regular maintenance and inspections to ensure that their lubrication system is functioning properly and to prevent malfunctions.

Therefore, the bellow cylinder, with its low maintenance requirements and lack of need for lubrication, is often more suitable for applications where equipment stability and long-term operation are critical. Its design simplifies the system, reducing maintenance costs and downtime, while enhancing overall efficiency and reliability.

Applications of air springs in other fields

- Rubber springs for food processing in vibrating tables

- Air springs used in the mining and construction field

- Convoluted bellow cylinder used in various production machines

- Air springs used in electric overhead traveling cranes

- Rubber air spring shock isolators in the Mining Industry

- Rubber air bellows used in bevelling machines

Get A Free Quotes