Rubber shock-absorbing cylinders are used in amusement parks

Rubber shock-absorbing cylinders are commonly used in amusement parks to enhance ride safety and comfort. They help to reduce vibrations and provide smooth, stable performance during high-impact motions. These cylinders are designed for durability and efficiency in dynamic environments.

Rubber Air Springs in Amusement Park Rides

Applications and Solutions of Rubber Air Springs in Amusement Park Rides

In amusement and theme parks, the safety, comfort, and performance of rides are of utmost importance. To meet these demands, rubber air springs have become a key technological solution, widely used in various attractions such as roller coasters, spinning rides, swings, and more. These air springs, through their unique air suspension systems, effectively absorb shocks, reduce vibrations, and ensure smooth and comfortable passenger experiences.

Role of Rubber Air Springs

Shock Absorption and Suspension Systems

Rubber air springs primarily serve as shock absorbers and suspension systems in amusement rides. During rapid acceleration, sharp turns, or high drops, they effectively absorb shocks and vibrations, minimizing damage to both the structure and passengers. By adjusting the air pressure, air springs provide the right amount of cushioning, avoiding excessive impact and discomfort.Dynamic Adjustment

The rubber air spring system can be dynamically adjusted to meet the varying needs of different rides. By altering the air pressure and the degree of spring deformation, precise control over the suspension’s firmness and elasticity is achieved, allowing it to adapt to different speeds and loads. For example, during the ascents and descents of a roller coaster, the air spring system can automatically adjust its support strength to maintain stability and comfort.Improved Safety and Durability

Rubber air springs not only improve the comfort of amusement rides but also enhance their durability. Over extended periods of use, these air springs effectively distribute loads, reducing the pressure on the structure and prolonging the lifespan of the equipment. Additionally, their shock-absorbing function helps reduce structural damage caused by vibrations, thus enhancing ride safety.

Solutions: Design and Application of Rubber Air Springs

To achieve optimal performance, the application of rubber air springs in amusement park rides requires careful design and customization. Below are some common solutions:

Custom Air Spring Design

Air springs are designed based on the type, size, and load requirements of the ride. Different types of attractions (such as roller coasters, flying chairs, bumper cars, etc.) require air springs with varying specifications and strength. For example, roller coasters may need higher pressure and greater load-bearing capacity, while spinning rides may require softer springs to ensure a comfortable ride.Optimized Pressure Control System

Air spring systems are typically equipped with intelligent pressure control systems that can monitor and adjust air pressure in real-time to adapt to varying operating conditions. With this smart control, pressure changes can respond instantly to changes in the ride’s acceleration, ensuring stable support even during high-speed or intense movements.Weather Resistance and Longevity

Since amusement park rides operate in all weather conditions, the materials and design of the air springs must exhibit excellent weather resistance and durability. Rubber materials are often exposed to sunlight, rain, temperature fluctuations, and other external factors, so high-performance rubber materials are used to extend their lifespan while ensuring stable performance in extreme environments.

Conclusion

Rubber air springs, as an efficient shock absorption and suspension solution, play an essential role in amusement park rides. Through customized design and intelligent control systems, they not only enhance ride comfort but also improve safety and durability. In the future, as technology continues to advance, rubber air springs will play an increasingly important role in amusement parks and other complex mechanical systems, providing better experiences for visitors.

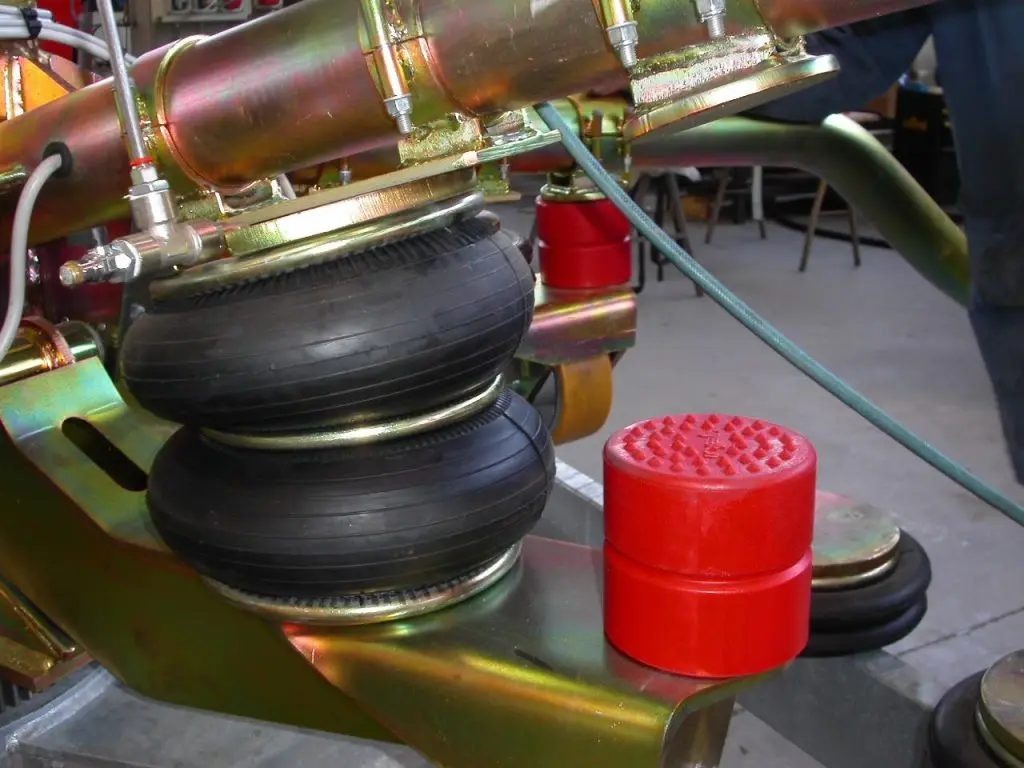

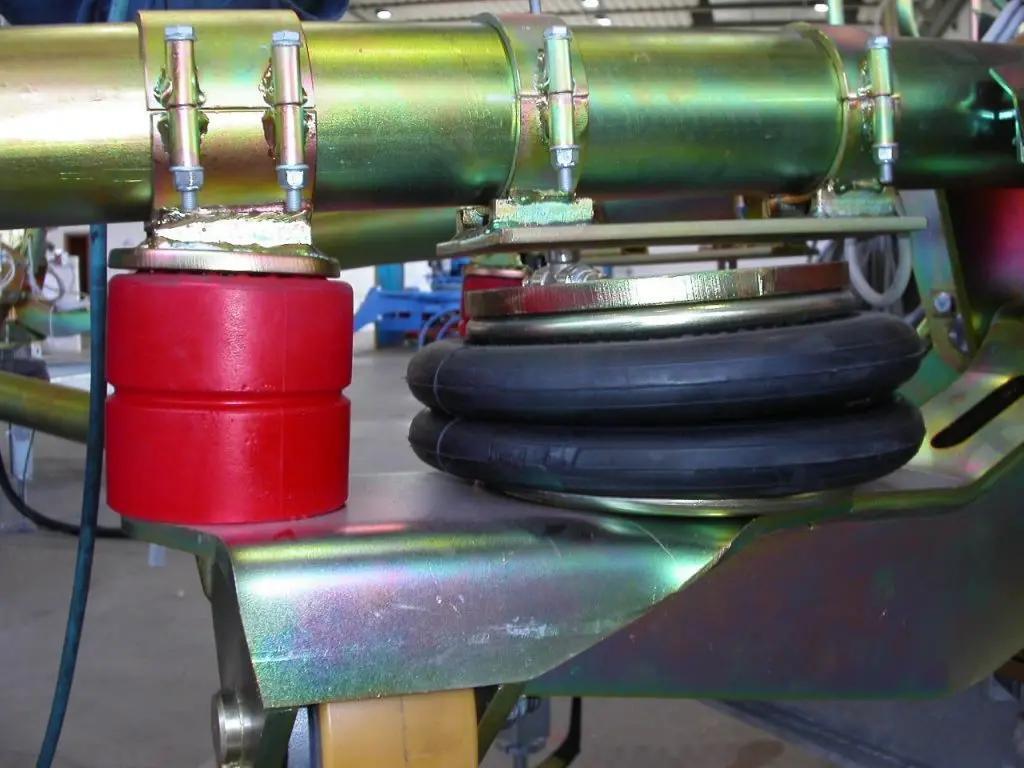

Principle of Air Bellow Expansion

An air bellow (also known as an air spring or air bag) is made of flexible rubber or composite materials and has an accordion-like structure. When air is pumped into the bellow, the air pressure causes the bellow to expand, increasing its volume. The expanded bellow can provide suspension, cushioning, shock absorption, or adjustment functions. As the pressure changes, the shape and function of the air bellow adjust accordingly, enabling it to adapt to different working conditions.

Applications of air springs in other fields

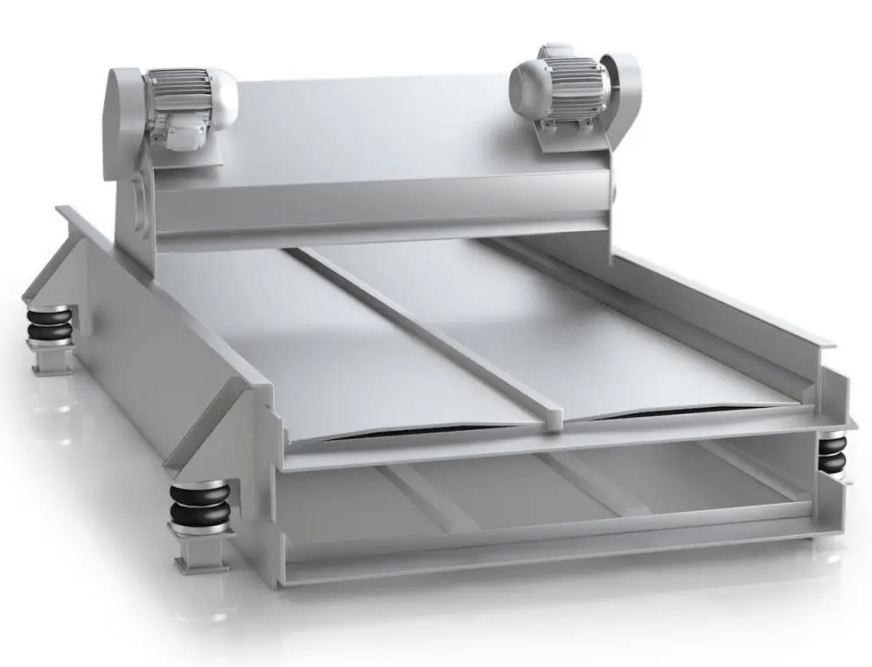

- Rubber springs for food processing in vibrating tables

- Air springs used in the mining and construction field

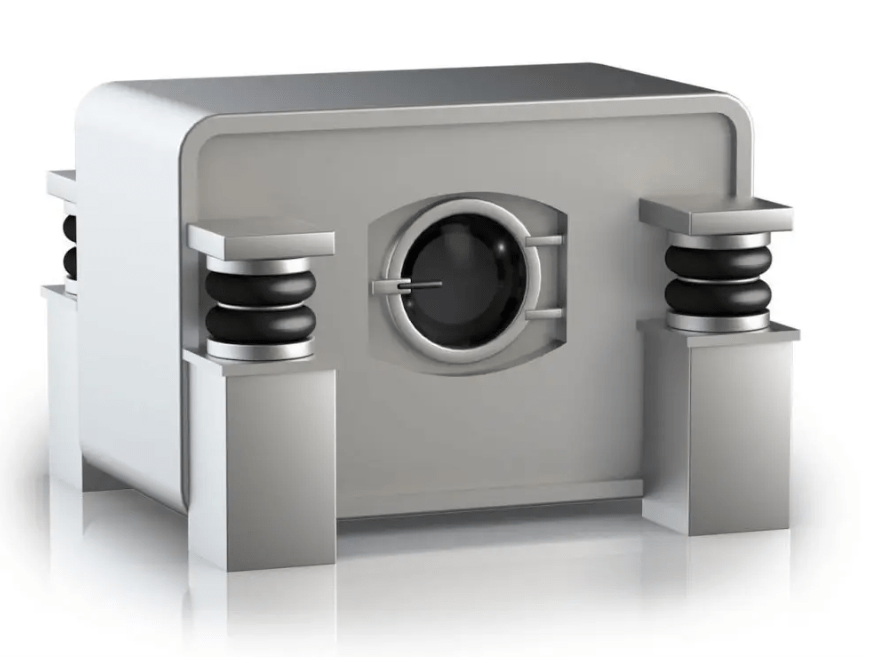

- Convoluted bellow cylinder used in various production machines

- Air springs used in electric overhead traveling cranes

- Rubber air spring shock isolators in the Mining Industry

- Rubber air bellows used in bevelling machines