Why Are Air Springs Essential for Large Brick-Making Machines?

Large brick-making machines face severe vibration issues, leading to frequent downtime and costly repairs. Air springs provide efficient vibration control, enhancing machine performance and extending equipment life.

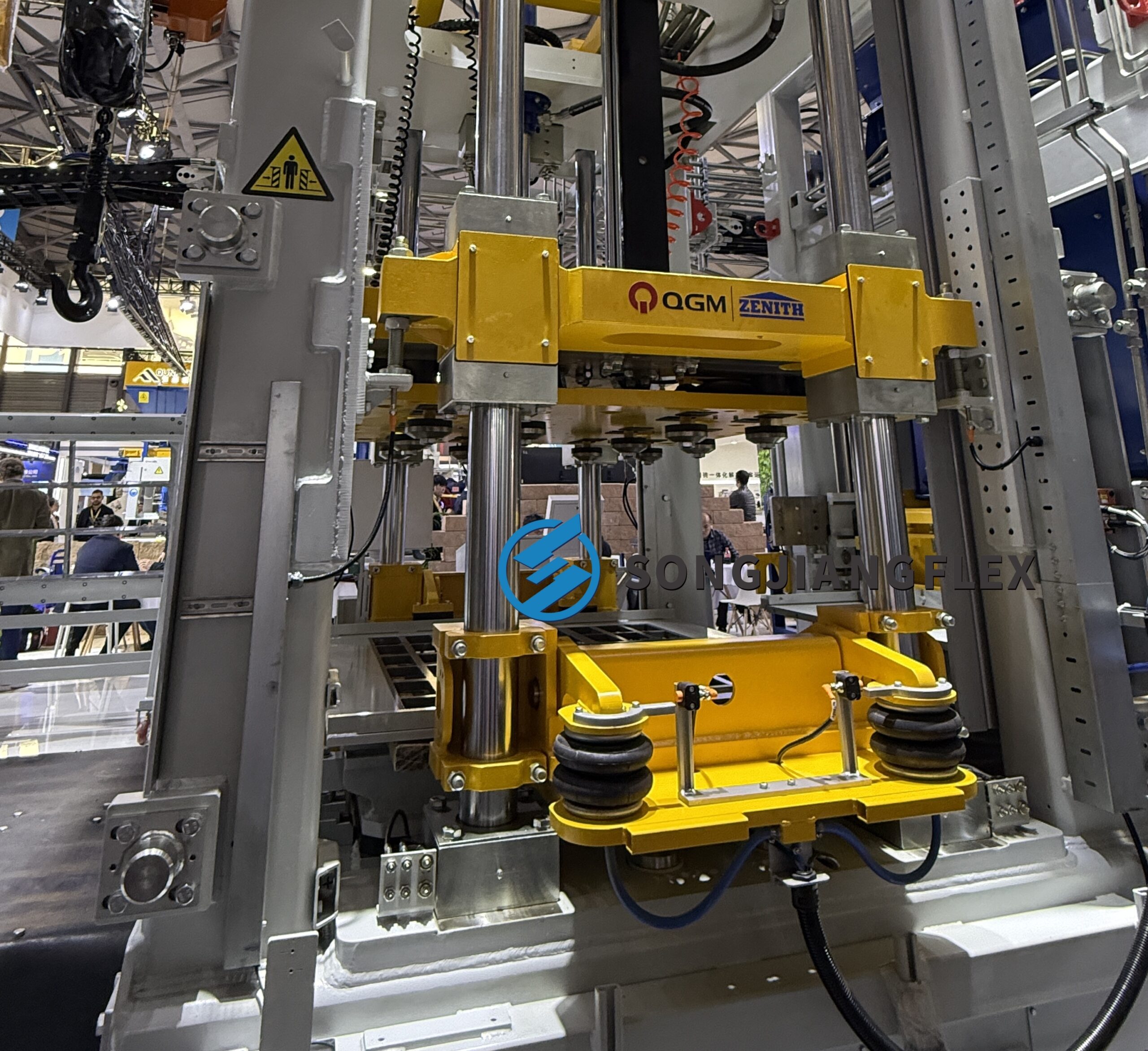

High-quality air springs offer reliable air spring vibration isolation, ensuring brick-making machine stability. They absorb shocks, reduce wear on key components, and improve production efficiency, making them an ideal solution for heavy-duty brick-making equipment.

Discover how air springs protect, stabilize, and optimize large-scale brick-making machines for maximum efficiency.

1. Why Use Air Springs Instead of Traditional Rubber Mounts?

Traditional rubber mounts in large brick-making machines often deteriorate under heavy loads, causing uneven vibration absorption and reduced equipment lifespan.

Air springs outperform rubber mounts with higher load capacity, better durability, and more stable vibration control, supporting industrial vibration solutions for heavy machinery.

Compared with mechanical or rubber mounts, air springs provide adjustable pneumatic suspension that adapts to load variations. They ensure longer equipment lifespan, reduce maintenance frequency, and enhance machine performance, making them indispensable in modern brick-making factories.

2. How Do Air Springs Improve Vibration Isolation in Brick-Making Machines?

Excessive vibration in brick-making machines can damage sensitive components and compromise operational safety, requiring an effective isolation solution.

Air spring vibration isolation and vibration damping ensure brick-making machine stability, minimizing shock transmission to critical machine parts.

By absorbing machine oscillations and evenly distributing forces, air springs protect brick machine components from fatigue and wear. This vibration control not only safeguards machinery but also enhances production precision, reducing downtime and operational costs.

3. What Types of Air Springs Are Commonly Used in Large Brick-Making Machines?

Different brick machine applications require specific types of air springs to handle varying loads and operational conditions.

Common types of air springs include industrial air springs, cylindrical air springs, and rolling-lobe air springs, all tailored for heavy-duty brick machine components.

Industrial air springs can be customized to fit specific brick-making equipment, offering high load capacity, flexible installation, and precise pneumatic suspension. The choice of air spring type affects both vibration isolation performance and long-term equipment durability.

4. How Do Air Springs Affect the Lifespan of Brick-Making Equipment?

Vibration and mechanical shocks accelerate wear and tear, reducing the overall lifespan of brick-making machines.

Air springs durability protects equipment, extending equipment lifespan and reducing maintenance requirements.

By cushioning impacts and evenly distributing load stresses, air springs minimize component fatigue. Regularly integrated air springs lead to lower repair costs, improved operational stability, and longer life for brick machine parts, enhancing overall factory productivity.

5. Can Air Springs Reduce Noise in Brick-Making Factories?

High vibration levels in brick factories generate significant noise, impacting worker safety and operational comfort.

Air springs noise reduction improves factory noise control by absorbing vibrations and dampening sound transmission.

Air springs not only protect machinery but also reduce factory noise, creating a quieter and safer work environment. Vibration damping limits resonance in machine structures, providing effective industrial noise control without compromising performance.

6. What Are the Load-Bearing Advantages of Air Springs in Heavy Machinery?

Heavy brick-making machines require high-capacity vibration support to maintain operational stability under continuous load.

Air spring load capacity supports heavy machinery, ensuring industrial vibration control and stable brick-making operations.

Adjustable air pressure allows air springs to adapt to varying loads, maintaining stability and minimizing stress on mechanical components. This enhances durability of brick machine parts while preventing structural fatigue under heavy production conditions.

7. How Do Air Springs Contribute to Energy Efficiency in Brick Production?

Machine vibrations and impacts consume extra energy, reducing production efficiency.

Energy saving air springs optimize efficient brick production via pneumatic suspension, reducing unnecessary energy consumption.

By absorbing shocks and smoothing machine operation, air springs minimize energy losses caused by vibration and impact. This not only lowers power consumption but also enhances process efficiency, contributing to more sustainable and cost-effective brick-making operations.

8. How Are Air Springs Installed and Maintained in Large-Scale Brick-Making Machines?

Proper installation and maintenance are critical to ensure air springs deliver optimal performance and longevity.

Air spring installation and maintenance tips include checking connections, securing mounts, and monitoring air pressure to protect brick machine parts.

Installation requires attention to structural support, airtight connections, and secure fasteners. Maintenance involves periodic inspection of air tightness, cleaning debris, and adjusting air pressure according to load and seasonal conditions, maximizing performance and lifespan.

9. How Do Air Springs Compare to Traditional Mechanical Springs in Brick-Making Machines?

Mechanical springs are limited in load capacity and vibration isolation, especially for heavy brick-making machines.

Air springs vs mechanical springs demonstrate superior industrial vibration solutions, enhancing machine performance and durability.

Air springs offer adjustable elasticity, higher load-bearing capacity, and superior vibration damping. They maintain stability under heavy loads and continuous operation, making them the preferred choice for modern industrial brick-making equipment.

High-quality air springs from Songjiangflex ensure large brick-making machines achieve stability, noise reduction, energy efficiency, and longer equipment lifespan.