Why Do Semiconductor Equipment Use Automatic Leveling Air Spring Isolators?

Semiconductor manufacturing is one of the most precision-demanding industries in the world. The slightest vibration, tilt, or instability can cause wafer defects, reduce yield, and increase production costs. Traditional vibration isolation methods, such as mechanical springs, often fail to meet the accuracy and stability requirements of modern fabs. Automatic leveling air spring isolators address this by combining vibration isolation with precise self-leveling capabilities, ensuring tools remain aligned even during floor shifts, thermal expansion, or nearby equipment operation.

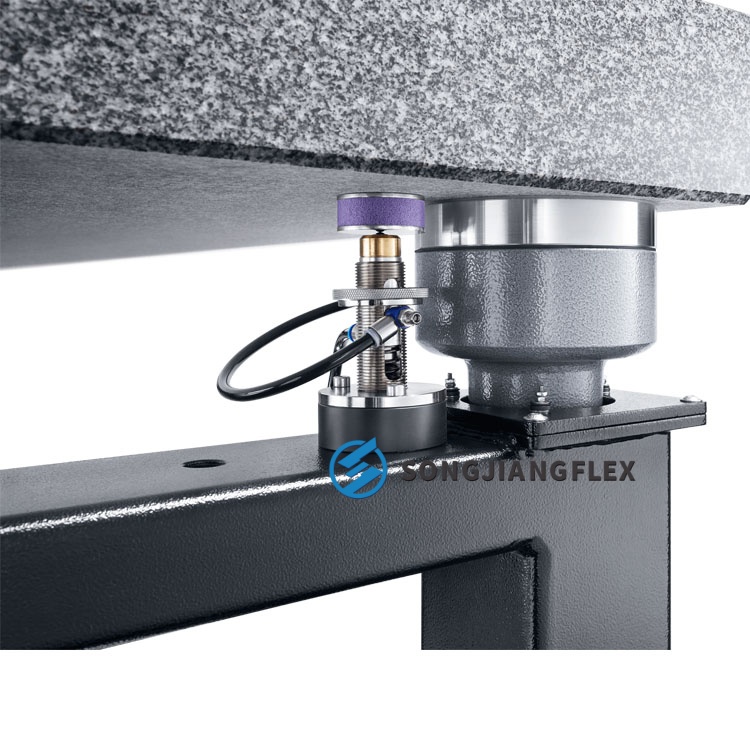

Automatic leveling air spring isolators stabilize semiconductor equipment by combining vibration isolation with self-leveling functions. They minimize floor vibration, maintain tool alignment, and enhance process precision in lithography, wafer processing, and metrology instruments. Unlike mechanical springs, they provide cleanroom-ready, high-precision air leveling systems that improve yield, throughput, and reliability in semiconductor production lines. Additionally, their adaptive response ensures consistent performance across variable load conditions and environmental factors.

Semiconductor fabs demand ultra-stable environments where nanometer-level precision determines success. From lithography to packaging, automatic leveling air spring isolators play a crucial role in protecting sensitive machines from vibration, tilt, and environmental disturbances. Below, we explore their functions, advantages, and applications in semiconductor equipment.

How Do Automatic Leveling Air Spring Isolators Improve Precision in Semiconductor Lithography Equipment?

Lithography is the backbone of chip fabrication, where even the slightest misalignment can ruin an entire batch. Automatic leveling air spring isolators ensure lithography tools remain perfectly aligned, counteracting floor vibration, structural shifts, and micro-tilt caused by load changes. With semiconductor lithography vibration isolators, manufacturers achieve consistent exposure accuracy and reduced defects.

These isolators actively adjust the tool platform in real time to compensate for thermal drift, operator-induced floor pressure, and nearby machine vibrations. The result is highly repeatable feature patterning with minimal overlay error, essential for advanced nodes below 7nm.

What Role Do Vibration Isolation Systems Play in Wafer Processing Machines?

Wafer processing involves grinding, polishing, and etching, all requiring extreme stability. A semiconductor vibration isolation system with air spring isolators for wafer processing absorbs disturbances from pumps, conveyors, and nearby machinery. This guarantees smooth wafer handling and prevents micro-cracks that lower yield.

In addition, isolation systems maintain planarity across the tool bed, ensuring uniform etching, deposition, and chemical mechanical polishing (CMP). By reducing transmitted vibrations, the system helps achieve higher device reliability, lower defect density, and consistent process outcomes, crucial for high-volume fabs.

Why Is Automatic Leveling Important for Semiconductor Metrology Instruments?

Metrology tools measure dimensions at the nanometer scale. Any tilt or platform instability directly affects measurement accuracy. An air spring isolator for metrology equipment with a high-precision air leveling system maintains consistent measurement baselines, enabling precise alignment for CD (critical dimension) measurement, overlay inspection, and defect review.

Automatic leveling compensates for both static and dynamic loads, floor unevenness, and environmental changes, which is vital for tools like AFMs, SEMs, or optical CD metrology systems. Maintaining a stable measurement reference ensures quality compliance, reduces rework, and accelerates throughput.

How Do Air Spring Isolators Reduce Floor Vibration Impact in Cleanroom Environments?

Cleanrooms house hundreds of sensitive tools operating simultaneously. Even minimal floor vibrations, from footsteps, HVAC systems, or nearby equipment, can compromise process stability. Cleanroom vibration isolation solutions using air spring vibration dampers provide stability while meeting contamination-free standards.

These systems operate silently and without mechanical contact, preventing particle generation. They also support varying load weights while maintaining consistent damping performance, allowing fabs to run multiple high-precision machines in proximity without cross-interference.

What Are the Advantages of Using Air Spring Isolators Over Mechanical Springs in Chip Manufacturing Machines?

Mechanical springs suffer from wear, inconsistent damping, and temperature sensitivity. Precision air spring vibration control offers adaptive damping, self-leveling, and higher frequency isolation. Active leveling air isolators for semiconductor machines maintain tool alignment under variable loads, reduce settling time, and enhance process repeatability.

Compared to mechanical alternatives, air springs can integrate sensors to provide real-time load and vibration feedback, supporting predictive maintenance and enabling automated fab monitoring. This combination improves yield, reduces downtime, and extends equipment lifespan.

How Does Automatic Leveling Enhance Throughput in Semiconductor Production Lines?

In production lines, downtime due to re-leveling or misalignment is costly. Automatic leveling systems maintain stability without manual intervention. By reducing adjustment time, ultra-precision automatic leveling isolators boost throughput and allow continuous operation of wafer exposure, deposition, and inspection tools.

Moreover, automated systems respond to load changes dynamically, keeping multiple tools perfectly leveled and synchronized, which reduces bottlenecks, improves line balancing, and optimizes fab utilization.

Can Air Spring Isolators Improve Yield Rates in Wafer Inspection and Testing Equipment?

Yes. Air spring isolators for inspection machines stabilize microscopes, scanners, and test stations. They prevent imaging distortion caused by vibration, floor tilt, or environmental fluctuations, allowing faster and more accurate defect detection.

Stable platforms result in higher measurement repeatability and reduced false rejections. Over time, this improves overall wafer yield, minimizes scrap costs, and accelerates data acquisition during high-volume inspection cycles.

What Are the Main Design Considerations for Air Spring Isolators in Semiconductor Fabs?

Designers must consider air pressure stability, temperature effects, vibration frequency spectrum, load capacity, and integration with fab automation. Semiconductor tool vibration dampers must be compact, contamination-free, and energy-efficient.

Proper design ensures maximum isolation with minimal footprint, accommodates different machine weights, and enables rapid adjustment for tool reconfiguration. Advanced systems may also include active sensors for monitoring floor vibration and automatic load redistribution.

How Do Air Spring Vibration Isolators Contribute to Ultra-Precision Alignment in Semiconductor Tools?

Ultra-precision alignment is critical for EUV lithography, metrology, and wafer bonding. Ultra-precision automatic leveling isolators provide sub-micron stability, compensating for floor unevenness, dynamic loads, and environmental disturbances.

By maintaining exact horizontal and vertical alignment, these isolators prevent overlay errors, improve yield, and ensure high device performance, especially in advanced semiconductor nodes where tolerances are extremely tight.

Why Do Semiconductor Packaging Machines Require Active or Passive Air Spring Isolators?

Packaging machines handle delicate die bonding, molding, and assembly. Both active and passive air spring isolators for semiconductor machines minimize vibration transmission, protecting fragile chips and ensuring consistent assembly quality at high throughput.

They also reduce tool wear and prevent micro-misalignment, which can lead to bonding defects, short circuits, or package failure, making them essential for high-volume packaging lines.

What Is the Difference Between Active Vibration Control and Automatic Leveling Air Spring Isolators in Semiconductor Applications?

Active vibration control detects and cancels vibrations in real time, ideal for high-frequency disturbances. Automatic leveling air spring isolators focus on maintaining precise horizontal and vertical stability, compensating for floor tilt and uneven loads.

Many fabs combine both approaches: active control handles transient vibrations, while leveling air springs ensure long-term positional accuracy. This hybrid strategy maximizes equipment performance, uptime, and wafer quality.

How Does Temperature and Air Pressure Stability Affect Air Spring Isolator Performance in Semiconductor Machines?

Temperature fluctuations and air pressure variations affect isolator stiffness and leveling accuracy. A well-designed automatic leveling air spring isolator maintains consistent performance under variable environmental conditions, ensuring vibration isolation, precise leveling, and reproducible results for all tools.

Stable pressure and temperature regulation are especially critical in cleanrooms where even minor shifts can cause misalignment in lithography or metrology equipment, impacting device quality and yield.

Automatic leveling air spring isolators are indispensable in semiconductor fabs, where precision and stability define success. By combining vibration damping with self-leveling, they enhance lithography accuracy, protect wafer processing tools, stabilize metrology systems, and improve yield in inspection processes. Compared with mechanical alternatives, they deliver cleaner, more reliable, and more efficient solutions—helping the semiconductor industry achieve ultra-precision and higher throughput. The benefits of automatic leveling air spring isolators extend across lithography, inspection, packaging, and cleanroom environments.

One Response

Hi , I do believe this is an excellent blog. I stumbled upon it on Yahoo , i will come back once again. Money and freedom is the best way to change, may you be rich and help other people.