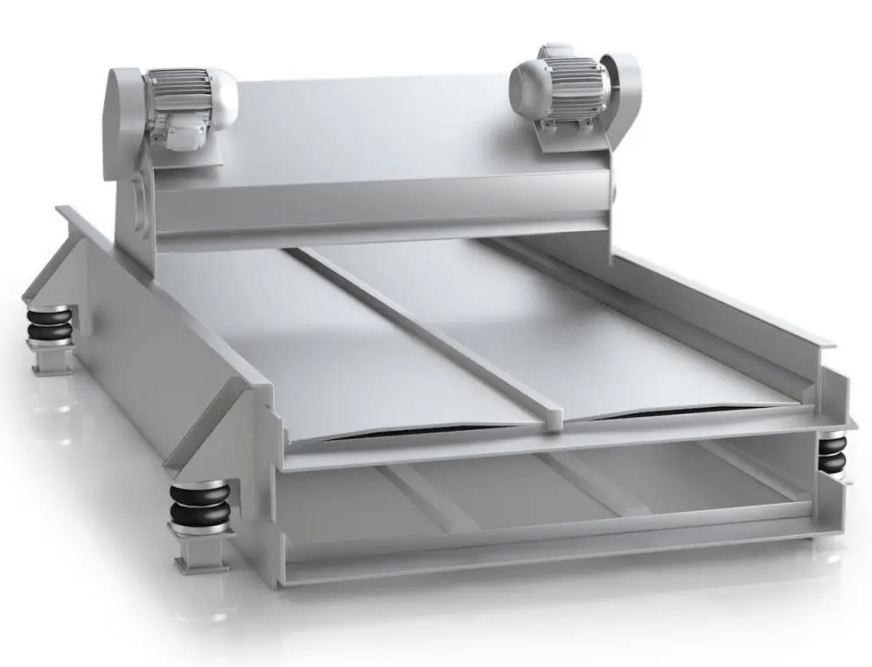

Industrial air springs used in pulp mills

Industrial air springs in paper mills are essential components used to absorb vibrations and shocks in various machinery. These air springs help maintain smooth operation of equipment such as presses, conveyors, and drying cylinders by providing flexible support and reducing mechanical wear. Their ability to handle heavy loads and adjust to varying pressure levels ensures optimal performance and extends the lifespan of the machinery in a paper mill setting.

Industrial air springs for paper mills

Application of Industrial Air Springs in the Papermaking Industry

Industrial air springs are widely applied in the papermaking industry, and their importance cannot be overstated. Here are the specific applications of industrial air springs in papermaking equipment:

Mitigating Vibration and Shock:

In papermaking equipment such as paper dryers, calenders, beaters, and presses, industrial air springs are used to mitigate the intense vibrations and shocks generated by high-speed operation. This buffering effect helps extend the service life of the equipment and reduce downtime, thereby enhancing production efficiency.Support and Stability:

By adjusting the internal air pressure, air springs provide stable support for papermaking equipment to adapt to different loads. This support ensures the smoothness of the equipment during high-speed operation, contributing to improved paper quality and operational efficiency.Bearing and Conveyor Belt Support:

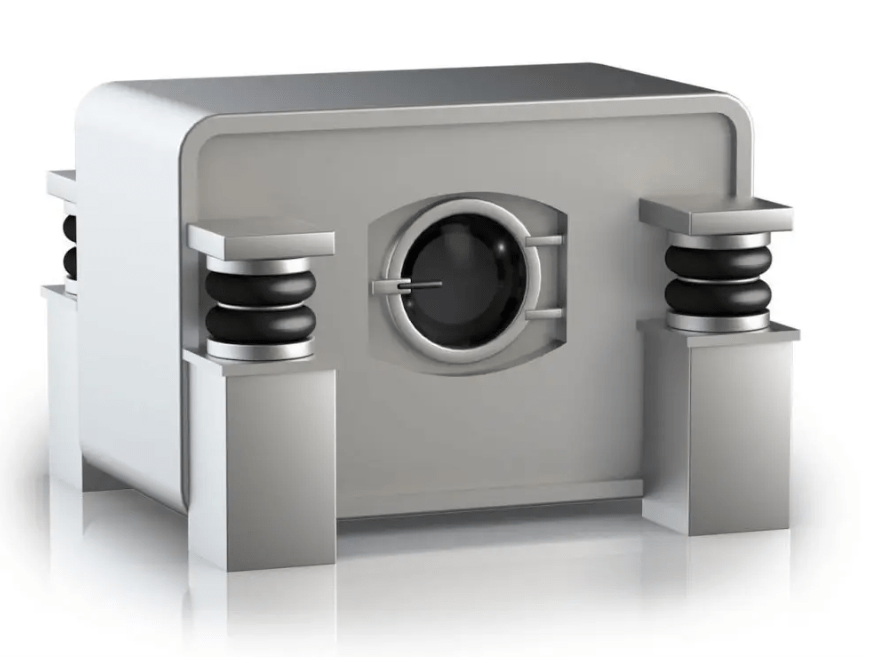

In the bearing support of papermaking equipment, air spring systems can effectively reduce friction resistance and wear on the bearings, enhancing the precision and reliability of the equipment. They are also used to support conveyor belts, reducing friction resistance and wear, and extending their service life.Vibration Isolation:

For vibration-sensitive equipment components, air spring systems can effectively isolate mechanical vibrations, protecting the precision and reliability of the equipment and ensuring the stability and continuity of the papermaking process.Optimizing the Production Environment:

The efficient shock absorption performance of air springs not only helps reduce equipment noise and vibration but also creates a quieter and more stable production environment. This improvement in the environment contributes to enhanced employee efficiency while ensuring employee safety and health.1

In summary, industrial air springs are diversely and widely applied in the papermaking industry. Their unique advantages in shock absorption, support, and stability provide powerful guarantees for the efficient operation of papermaking equipment and the improvement of paper quality

The Important Role of Industrial Air Springs in the Papermaking Industry

The important role of industrial air springs in the papermaking industry is mainly reflected in the following aspects:

1. Enhancing Equipment Stability: Air springs, through precise air pressure regulation, adapt to load changes in real time, ensuring the smooth operation of papermaking equipment at high speeds. This stability is crucial for the papermaking process, directly impacting the quality of the paper and the lifespan of the equipment.

2. Reducing Equipment Wear and Failures: Air springs effectively absorb and mitigate equipment vibration, reducing wear caused by long-term operation and extending the machine’s service life. They also lower the frequency of equipment repairs and part replacements, minimizing downtime and, consequently, reducing operational costs for the enterprise.

3. Improving Production Efficiency and Product Quality: The shock absorption capabilities of air springs help maintain efficient equipment operation, enhancing overall production efficiency in paper mills. During key processes such as paper forming and pressing, the use of air springs reduces vibration-induced defects, improving paper quality and product pass rates.

4. Enhancing the Working Environment: Not only do air springs excel in shock absorption, but they also provide excellent sound insulation. They significantly reduce noise pollution within paper mills, creating a quieter and more comfortable working environment for employees, thereby improving work efficiency and job satisfaction.

In summary, industrial air springs play a vital role in the papermaking industry, demonstrating their irreplaceable advantages from enhancing equipment stability and reducing wear and failures to improving production efficiency and product quality, as well as enhancing the working environment.

Applications of air springs in other fields

- Rubber springs for food processing in vibrating tables

- Air springs used in the mining and construction field

- Convoluted bellow cylinder used in various production machines

- Air springs used in electric overhead traveling cranes

- Rubber air spring shock isolators in the Mining Industry

- Rubber air bellows used in bevelling machines