How Do Air Springs Serve as the Stability Core of Ultra-Precision 2D Vision Measuring Machines?

Measurement errors often arise from minute vibrations, disrupting precision. Incorporating air springs effectively isolates these vibrations, providing a stable foundation for high-accuracy vision measuring systems.

Precision air springs offer low-frequency vibration isolation and height adjustability, making them ideal for ultra-precision 2D vision measuring machines. They minimize micro-vibrations and enhance measurement accuracy, stability, and repeatability, becoming essential components in modern metrology equipment.

Let’s explore how air spring isolators transform high-precision measurement in industrial environments.

1. Why Is Stability So Critical for 2D Vision Measuring Machines?

Stability is crucial because even microscopic vibrations can distort optical measurements in vision measuring systems.

Stable mounting ensures the precision and repeatability essential for detailed dimensional analysis.

For vision measuring systems, the air mount provides a reliable base that minimizes movement and vibration, supporting highly accurate results in industries like electronics and precision manufacturing.

2. Why Is Vibration Isolation Critical for 2D Vision Measuring Systems?

Vibration isolation protects sensitive metrology equipment from environmental and mechanical disturbances.

Effective vibration isolation enables precise readings by reducing the interference caused by ground vibrations or nearby machinery.

Metrology equipment vibration control, especially in ultra-precision devices, directly impacts the quality of measurement outcomes, preventing costly errors and rework in production.

3. What Role Do Air Springs Play in Vibration Isolation?

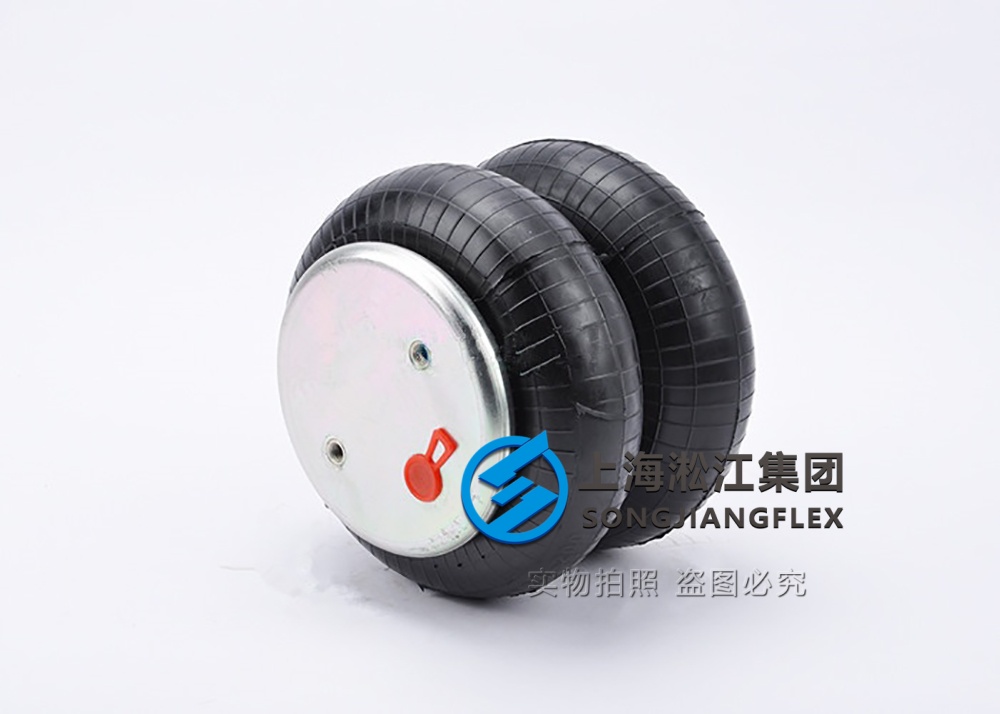

Air springs act as vibration isolation units that absorb and dampen low-frequency vibrations effectively.

These vibration isolation air springs use compressed air to create a cushioning effect, dynamically responding to load variations.

Compared to conventional isolators, air springs adaptively reduce vibration transmission, thereby protecting delicate measurement components and improving overall system stability.

4. What Makes Air Springs More Effective Than Coil Springs in Precision Instruments?

Ultra-precision air springs outperform coil springs due to their lower natural frequency and adjustable damping properties.

Pneumatic vibration isolators provide smoother, more controlled isolation, crucial for sensitive instruments requiring minimal disturbance.

This leads to enhanced protection against shock and vibration, reducing measurement deviations and increasing instrument longevity.

5. How Do Air Springs Enhance Measurement Accuracy in Ultra-Precision Machinery?

Precision air springs provide a consistent and stable support platform that isolates the instrument from external vibrations.

Air spring isolators for measuring machines improve accuracy by maintaining a steady environment, preventing data fluctuations caused by mechanical noise.

This enhanced stability ensures the high repeatability needed for critical measurements in fields like aerospace, electronics, and automotive manufacturing.

6. Can Air Suspension Technology Reduce Environmental Noise Interference in Metrology Equipment?

Anti-vibration air suspension units are designed to isolate equipment from ambient noise and structural vibrations.

By absorbing sound and mechanical energy, air suspension technology minimizes the impact of environmental noise on measurement accuracy.

This is especially beneficial in industrial environments where external disturbances could compromise sensitive metrology devices.

7. What Are the Advantages of Using Adjustable Air Springs in Imaging and Scanning Systems?

Height adjustable air springs allow precise tuning of suspension stiffness and platform height to match specific equipment needs.

These adjustable air springs optimize vibration isolation performance and provide flexibility in installation and calibration.

Their adaptability makes them ideal for diverse imaging and scanning systems requiring fine-tuned support for various payloads and operational conditions.

8. How Do Air Springs Contribute to Long-Term Stability and Repeatability in Coordinate Measuring Machines (CMMs)?

Air spring suspension for optical equipment offers sustained vibration damping and load support over prolonged use.

This long-term stability enhances measurement repeatability, reducing drift and ensuring consistent data collection in CMMs.

Reliable air springs minimize maintenance needs and extend the operational life of critical metrology systems.

9. What Is the Difference Between Passive and Active Air Spring Isolators in High-Precision Machines?

Passive pneumatic vibration isolators rely on inherent air cushioning without external control systems.

Active isolators integrate sensors and actuators to dynamically counteract vibrations in real-time.

Both types serve important roles, but active systems provide superior isolation for environments with complex or unpredictable vibration profiles.

10. How Does Air Spring Stiffness Tuning Affect Performance in Optical Measuring Equipment?

Precision air springs with adjustable stiffness allow optimization of damping characteristics tailored to specific instruments.

Fine-tuning stiffness improves isolation efficiency and reduces resonance effects, leading to clearer measurement signals.

Such tuning capabilities are critical in achieving peak performance in high-end optical measuring systems.

Air springs are indispensable for vibration isolation in modern metrology, offering unmatched stability, adjustability, and accuracy for ultra-precision vision measuring systems. Explore more about our air springs to enhance your equipment’s performance.