Why Are Damping Vibration Isolators Essential for Pump Rooms?

Pump rooms are essential areas within many industrial and commercial facilities. They house critical equipment like pumps, motors, and pipes that are integral to the operational processes. However, these systems often generate significant vibrations that can negatively affect equipment longevity, operational efficiency, and overall system stability. To combat these challenges, damping vibration isolators are key to maintaining smooth operations.

Vibration isolators are not just about reducing noise. They’re about protecting machinery, extending equipment lifespan, and ensuring optimal performance. Damping vibration isolators, specifically designed for pump rooms, offer solutions that effectively mitigate the harmful effects of vibrations.

What is a Damping Vibration Isolator?

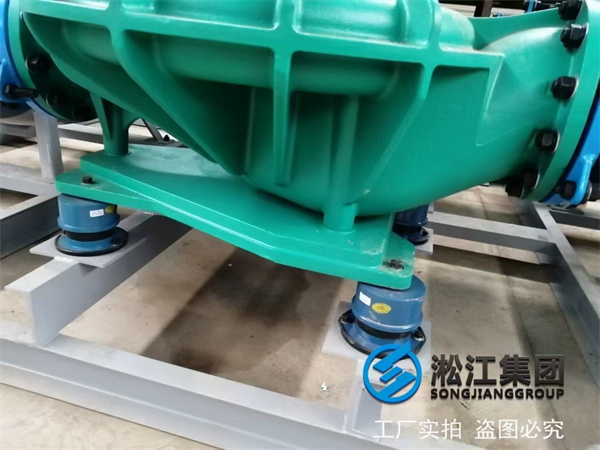

A damping vibration isolator is designed to absorb and reduce mechanical vibrations within a system, ensuring vibrations do not travel to sensitive parts of the equipment or surrounding structures. These isolators are especially important in environments like pump rooms, where vibrations from pumps and motors can be significant. They are designed with high-performance materials such as rubber, metal, or composites, each chosen based on the specific application needs.

For example, in pump expansion joints and duct vibration isolators, the material’s ability to absorb and dampen vibrations directly impacts system efficiency and noise reduction. These isolators are also used in more complex systems like rooftop condensing unit vibration isolation, where vibration from HVAC units must be controlled to prevent potential damage to the building structure or the system itself.

Why is a Vibration Damper Necessary?

A vibration damper is necessary to protect equipment from the harmful effects of vibration. Without damping, vibrations can spread throughout the system, causing mechanical failure, wear and tear, and noise. Vibration dampers act as a barrier to prevent the transmission of these vibrations, protecting critical components such as pumps, motors, and HVAC systems.

For example, in heat pump vibration isolation, dampers absorb the vibration energy generated by the pump and prevent it from affecting sensitive components. This significantly improves system performance and reduces maintenance costs. Additionally, vibration dampers help create a quieter environment by minimizing noise levels, which is especially crucial in residential and commercial settings.

What is the Difference Between an Isolator and a Damper?

While both vibration isolators and dampers serve the purpose of controlling vibrations, they work in different ways. An isolator is designed to prevent the transmission of vibrations from one part of the system to another, effectively isolating sensitive equipment. On the other hand, a damper works by absorbing the vibration energy and converting it into heat, reducing the intensity of vibrations.

Kinetics spring isolators, for instance, are used in pump systems to isolate vibrations, while vibration isolators for HVAC units protect against the spread of vibrations within the ducts and surrounding structures. Both isolators and dampers are crucial for maintaining system stability, but their functions are complementary.

Does Damping Reduce Vibration?

Yes, damping does reduce vibrations effectively. Damping materials absorb vibration energy and convert it into heat, which is then dissipated over time, lowering the overall intensity of vibrations. This process is critical in environments like pump rooms, where vibrations can negatively impact machinery and surrounding systems.

In duct vibration isolators and vibration isolators for HVAC systems, the damping process ensures that vibrations from motors, fans, or pumps are contained and do not interfere with the surrounding equipment or structures. This leads to reduced maintenance requirements, fewer equipment failures, and quieter operations.

What is the Function of a Vibration Damper?

The primary function of a vibration damper is to absorb and reduce the impact of mechanical vibrations that could harm equipment and disrupt operations. Vibration dampers convert the energy produced by vibrations into heat, which is then dissipated, reducing the intensity of the vibrations.

In pump systems, vibration dampers help prevent vibrations from causing damage to sensitive components such as pipes, valves, and motors. They also help reduce noise levels and improve overall system performance. Whether applied in rooftop condensing unit vibration isolation or heat pump vibration isolation, vibration dampers play an essential role in maintaining the efficiency and longevity of systems.

What is the Theory of Vibration Damping?

The theory behind vibration damping is simple: it involves the conversion of mechanical vibration energy into heat. When a vibration dampening material is introduced to a vibrating system, it resists the motion and dissipates the energy, reducing the amplitude of the vibrations. This results in a more stable and less noisy operation.

For example, kinetics spring isolators use this principle to absorb the vibrations generated by pumps and motors, preventing them from affecting the surrounding system. Vibration isolators for FCU (fan coil units) work on the same theory, isolating vibrations in HVAC systems to protect sensitive components and prevent operational disruptions.

What is a Good Vibration Isolator?

A good vibration isolator is one that effectively absorbs and isolates vibrations, ensuring that sensitive equipment is shielded from mechanical disturbances. The best isolators are made from durable materials that can handle the specific frequencies and intensities of the vibrations they are designed to control.

In applications like pump expansion joints, duct vibration isolators, and heat pump vibration isolation, a good isolator must be able to withstand continuous vibration without deteriorating over time. The material choice—such as rubber or composite materials—plays a crucial role in ensuring that the isolator can perform effectively and extend the life of the equipment it protects.

Summary

Damping vibration isolators are an essential part of maintaining the stability and longevity of pump room systems. By reducing vibrations and absorbing energy, they protect sensitive equipment, reduce noise, and ensure the overall efficiency of the system.