What Are Rubber Vibration Isolator Mounts and Why Are They Important?

Machinery vibrations can cause significant noise, wear, and decreased performance. Choosing the right vibration isolation solution is essential for improving equipment lifespan and operational efficiency. Rubber vibration isolator mounts, such as heavy duty vibration isolators and heavy duty rubber mounts, are key to minimizing these vibrations.

Rubber vibration isolator mounts, including heavy duty rubber mounts and rubber isolator bushings, effectively reduce vibrations in machinery, preventing damage and noise. These mounts enhance performance and extend the life of equipment.

Now, let’s take a deeper look into the different types of rubber vibration isolators and how they work.

What Are Rubber Vibration Isolator Mounts?

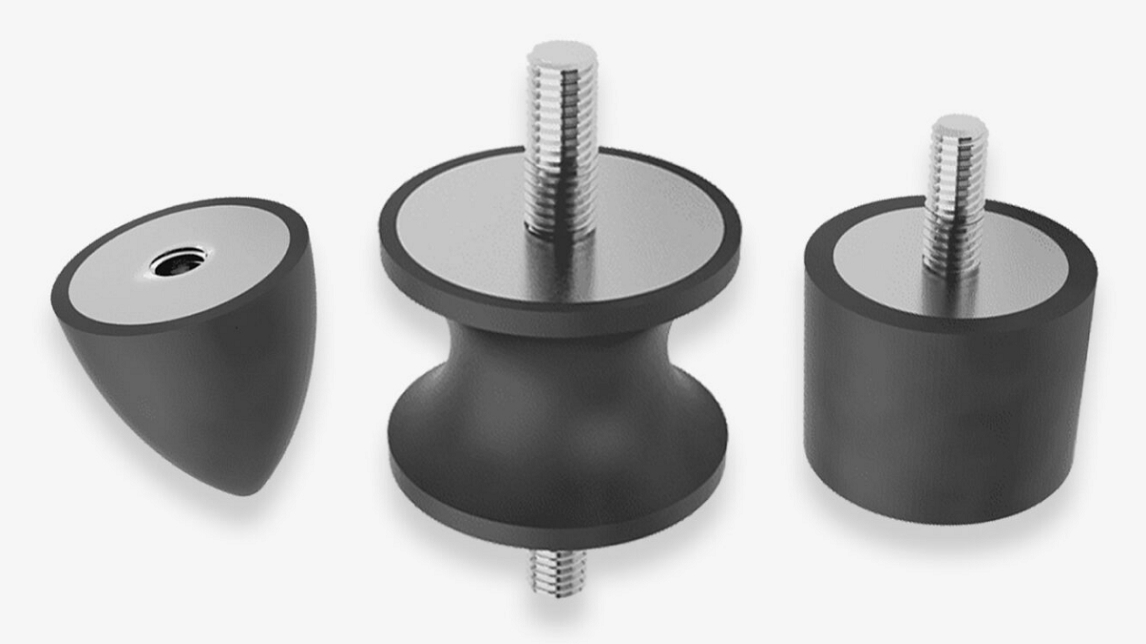

Rubber vibration isolator mounts are specialized components designed to absorb and isolate vibrations in machinery and equipment. These mounts are typically made from durable rubber materials like heavy duty rubber mounts, rubber isolator pads, or rubber isolator bushings.

Rubber vibration isolator mounts, including rubber isolator feet, help reduce vibrations in machines, preventing them from transferring to surrounding structures. This minimizes noise and prevents damage to sensitive machinery.

Rubber vibration isolator mounts come in various shapes and sizes, including cylindrical vibration isolators, to suit different machinery types. Their main function is to absorb vibrations and prevent them from traveling through machinery and structures. Industries such as manufacturing, construction, and automotive rely on these mounts to improve operational efficiency and extend equipment lifespan.

What Are Vibration Isolation Mounts?

Vibration isolation mounts are devices that prevent vibrations from traveling between machinery and the surrounding environment. By isolating vibrations, these mounts ensure smooth operation and prevent potential damage to both the equipment and the building.

Rubber vibration isolator mounts, such as rubber isolator bushings, are commonly used in industrial machinery to isolate vibrations and protect surrounding structures from noise and damage.

These mounts are commonly made from flexible rubber materials, including options like rubber isolator pads and rubber isolator feet. They are found in many applications, from HVAC systems to compressors, helping to enhance performance and minimize noise. The use of vibration isolation mounts is vital in ensuring system stability and equipment longevity.

Are Anti-Vibration Fan Mounts Worth It?

Anti-vibration fan mounts play a critical role in reducing the vibration and noise generated by industrial fans. These mounts help to maintain fan efficiency and extend the life of both the fan and other surrounding equipment.

Yes, anti-vibration fan mounts, like heavy duty vibration isolators, are worth the investment because they reduce noise, prevent wear and tear, and maintain operational efficiency.

Anti-vibration fan mounts, often made from rubber isolator bushings, are particularly useful in industries with large fan systems. By isolating vibrations, these mounts prevent vibrations from transferring to nearby machinery or structural components, ensuring a quieter and more efficient working environment.

What Is an Example of Vibration Isolation?

An example of vibration isolation is the use of rubber isolator pads in industrial machinery to prevent vibrations from traveling to the surrounding structure. These pads absorb the vibrations and reduce the noise produced by machines.

Rubber vibration isolator mounts, such as rubber isolator feet and isolator pads, are excellent examples of vibration isolation. They work by absorbing shock and preventing vibrations from spreading to the machine’s frame.

Common applications for rubber isolator pads and mounts include machinery like pumps, air conditioners, and transformers. These mounts prevent vibration-induced damage and reduce noise levels, enhancing both the safety and performance of the equipment. Additionally, they help to meet noise and vibration regulations in many industries.

What Is the Difference Between a Vibration Isolator and an Absorber?

Vibration isolators and absorbers serve different functions in managing vibrations. While isolators prevent vibrations from entering a structure, absorbers reduce the intensity of vibrations once they’ve been introduced.

Vibration isolators, such as heavy duty rubber mounts, prevent vibrations from entering a structure, while absorbers, like rubber isolator bushings, reduce the energy of the vibrations to minimize their impact.

Vibration isolators are designed to block vibrations entirely, whereas absorbers are used to dissipate vibration energy. Both are essential for reducing mechanical wear, improving equipment performance, and maintaining structural integrity. Choosing between them depends on the application and the level of vibration control required.

Do Engine Mounts Reduce Vibration?

Engine mounts are specifically designed to reduce the vibrations generated by engines, making them a crucial component in vehicles and heavy machinery.

Yes, engine mounts, especially heavy duty vibration isolators, help reduce engine vibrations by isolating the engine from the rest of the vehicle or machinery, ensuring smoother operation.

Engine mounts, made from durable rubber materials like rubber isolator bushings, play a vital role in reducing noise and vibrations in vehicles. By isolating engine vibrations, they improve overall vehicle comfort and prevent damage to surrounding components.

How Do I Choose an Anti-Vibration Mount?

Choosing the right anti-vibration mount involves considering various factors such as load capacity, vibration frequency, and the type of machinery involved. Materials like rubber isolators, including rubber isolator feet and heavy duty rubber mounts, are ideal for absorbing and reducing vibrations.

To choose the right anti-vibration mount, assess factors like vibration frequency and material compatibility. Rubber isolators, including cylindrical vibration isolators, are often the best choice for most industrial applications.

When selecting an anti-vibration mount, consider the environment and load capacity requirements. Rubber isolator mounts, such as those available at Home Depot or Napa, are popular for their versatility and effectiveness. It’s important to match the mount’s stiffness and size to the equipment’s needs to ensure optimal vibration isolation.

How Do Rubber Vibration Isolator Mounts Work?

Rubber vibration isolator mounts work by using the flexibility and elasticity of rubber to absorb and dissipate vibrations. These mounts are designed to minimize the transfer of vibration energy to surrounding structures.

Rubber vibration isolator mounts, such as rubber isolator bushings, absorb shock and vibration through the flexibility of rubber, preventing vibrations from reaching the surrounding equipment and structures.

Rubber isolators, such as cylindrical vibration isolators and heavy duty rubber mounts, are designed to absorb energy from vibrations. These mounts are used in a variety of applications, from HVAC systems to industrial machines, ensuring smoother operation and longer-lasting equipment.

Benefits of Using Rubber Vibration Isolator Mounts

Rubber vibration isolator mounts offer numerous benefits, including reduced noise, extended equipment life, and improved performance.

The primary benefits of rubber vibration isolator mounts, like rubber isolator pads and heavy duty rubber mounts, include improved machine durability, reduced noise, and enhanced safety.

These mounts help prevent vibration-induced wear and tear on machinery, resulting in fewer maintenance issues and lower downtime. Additionally, they enhance machine efficiency, reduce energy consumption, and create a quieter working environment.

Applications of Rubber Vibration Isolator Mounts

Rubber vibration isolator mounts are widely used in industries such as automotive, power generation, and HVAC systems to ensure smooth machine operation and prevent vibration-related damage.

Rubber vibration isolator mounts, including rubber isolator feet and heavy duty rubber mounts, are essential for preventing damage and reducing noise in machinery across various industries.

These mounts are used in various applications, from water pumps to industrial generators. Their ability to reduce vibrations and prevent noise makes them indispensable in many sectors, ensuring equipment longevity and improving overall system performance.

Summary

Rubber vibration isolator mounts, such as heavy duty rubber mounts and cylindrical vibration isolators, are crucial for reducing vibration, enhancing machine performance, and improving safety in various industries.