What Are Wire Rope Isolators and How Do They Work?

Is your machinery experiencing unwanted vibrations? Wire rope isolators could be the solution you need. These devices effectively isolate vibrations and protect your equipment from damage.

Wire rope isolators are a simple and effective solution for vibration isolation. Used in various industries, they prevent damage from vibrations and shocks, ensuring equipment longevity and smooth operations.

Let’s dive deeper into how wire rope isolators work and why they are the go-to choice for many industries.

What Are Wire Rope Isolators?

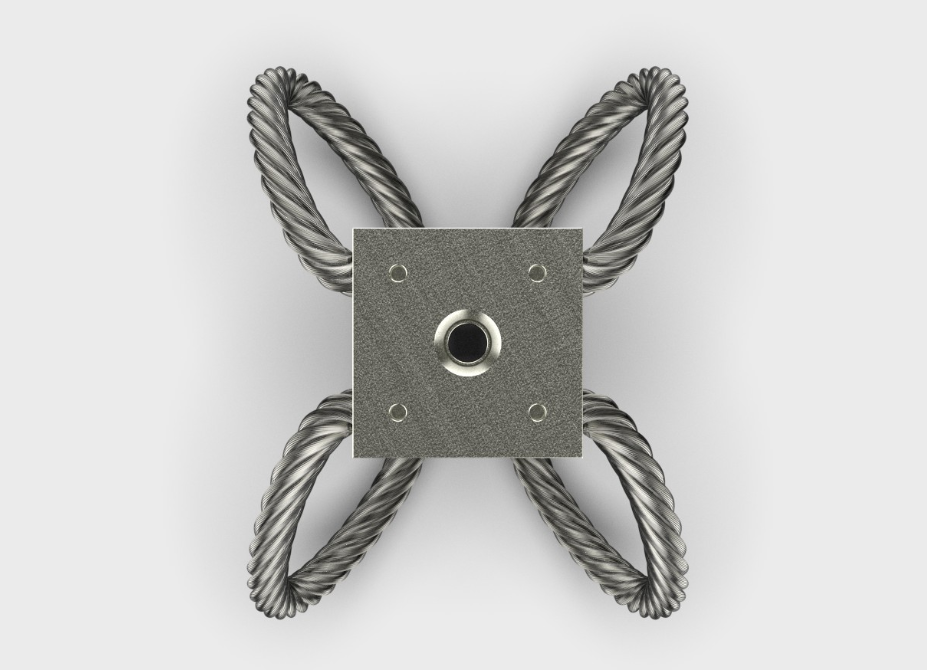

Wire rope isolators are mechanical devices used to reduce vibrations and shock loads in machinery.

They consist of multiple layers of wire rope arranged in a specific pattern to absorb and dissipate energy, offering superior vibration isolation compared to traditional materials.

Wire rope isolators are commonly used in applications requiring high vibration damping. They are designed to perform under extreme conditions, such as in aerospace, automotive, and industrial machinery. The flexibility of wire rope allows these isolators to handle varying load conditions and offer a reliable solution for vibration isolation.

What Type of Stopper Would You Use on Wire Rope?

Stoppers play an essential role in securing wire rope isolators and ensuring their effective operation.

Common types of stoppers used with wire rope isolators include rubber stoppers and metallic end caps, which help to secure the isolators and prevent unwanted movement.

Rubber stoppers provide a flexible solution, allowing for some movement while still providing vibration isolation. On the other hand, metallic end caps are more durable and provide a secure fit for isolators that operate in heavy-duty applications. Choosing the right stopper depends on the specific application and load requirements.

What Does a Cable Isolator Do?

Cable isolators are designed to reduce vibrations and prevent damage in cable systems.

These isolators help to absorb shocks and vibrations from machinery, ensuring that cables remain intact and free from wear and tear.

Cable isolators are often used in environments where cables are exposed to constant movement and vibrations, such as in industrial plants, aerospace systems, and automotive applications. They protect the cables and improve the overall performance and longevity of the system by preventing fatigue and damage caused by repeated vibrations.

What Are the Disadvantages of an Isolator?

While isolators offer many benefits, they also have some potential drawbacks.

Disadvantages may include limited performance in extreme conditions, higher initial cost, and potential for wear over time.

One of the primary disadvantages of isolators, including wire rope isolators, is that they may not perform well in extremely high or low temperatures. Additionally, over time, the isolators can degrade or lose their effectiveness, especially if they are exposed to harsh chemicals or constant vibration. It’s also important to factor in the cost of installation and maintenance when considering the use of isolators.

What Is the Purpose of an Isolator?

The primary purpose of an isolator is to prevent the transmission of vibrations and shocks to sensitive machinery and equipment.

By absorbing and dissipating energy, isolators protect machinery, reduce noise, and extend the lifespan of equipment.

Isolators are used in many industries to protect sensitive equipment from the harmful effects of vibrations. In industrial machinery, isolators help ensure the smooth operation of components like pumps, fans, and compressors. They are also crucial in sectors like aerospace, where the precision of instruments is critical, and in automotive applications to improve ride comfort and reduce noise levels.

Where Should an Isolator Switch Be Located?

Isolator switches are used to disconnect or isolate parts of a system for safety or maintenance purposes.

The location of an isolator switch is critical for easy access and safety. It should be positioned where it can be quickly reached in emergencies or during routine maintenance.

In industrial systems, isolator switches are often located near equipment that requires regular maintenance or in areas where safety is a concern, such as near electrical panels or hazardous machinery. The placement should ensure that the switch is easily accessible but not in a location where accidental activation can occur.

How Do Wire Rope Isolators Work?

Wire rope isolators operate on the principle of energy absorption through the flexing of steel cables.

When vibrations occur, the wire rope flexes, absorbing the kinetic energy and preventing it from reaching sensitive components.

The unique design of wire rope isolators allows them to work effectively across a wide frequency range. This makes them highly versatile for different applications. Their performance is also less influenced by temperature changes, unlike other isolators, making them ideal for harsh environments.

Applications of Wire Rope Isolators

Wire rope isolators are used in a variety of industries where vibration control is critical.

From aerospace and automotive to industrial machinery, wire rope isolators provide crucial vibration damping to protect equipment.

In the aerospace industry, wire rope isolators are used to protect aircraft components from engine vibrations. In the automotive sector, they help reduce noise and vibrations in vehicles. These isolators are also common in power generation plants, where they reduce vibration in turbines and compressors.

Advantages of Using Wire Rope Isolators

Wire rope isolators offer several key advantages that make them a preferred choice for vibration isolation.

These include their durability, ease of installation, and ability to handle a wide range of vibrations and shock loads.

One of the primary benefits of wire rope isolators is their ability to function effectively in both high and low-frequency vibration environments. Additionally, they are resistant to environmental factors such as temperature changes, corrosion, and chemicals, which makes them ideal for a variety of industrial applications.

Selecting the Right Wire Rope Isolator for Your Needs

Choosing the right wire rope isolator involves considering several factors, including load capacity, vibration frequency, and environmental conditions.

To ensure optimal performance, it’s important to select an isolator that matches your specific requirements in terms of vibration frequency and load-bearing capacity.

When selecting wire rope isolators, make sure to consult with a supplier who can recommend the best product based on your application. Considerations such as size, material, and design can significantly affect the performance of the isolators.

Summary:

Wire rope isolators are an efficient solution for vibration control, offering numerous advantages in various industrial applications. They provide reliable protection for machinery and ensure long-term performance.