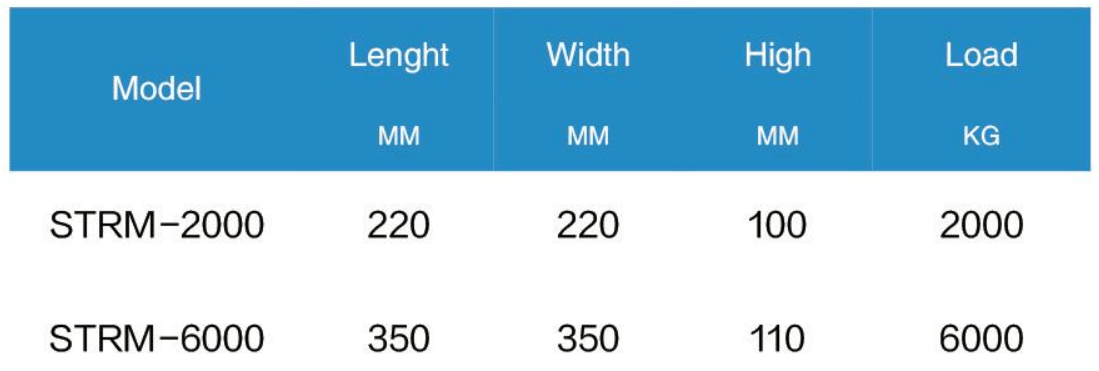

STRM Stabilizing Rubber Isolator

KQJZ-B Type Die Cutting Machine Damping Air Isolator

Frequently Asked Questions

What systems are STRM Stabilizing Rubber Isolator used in?

The STRM Stabilizing Rubber Isolator is used in various systems that require vibration reduction and stability, such as:

- Industrial Machinery – To reduce vibration and noise, improving operational efficiency and equipment lifespan.

- Construction Equipment – Ensures smoother operation and minimizes wear and tear on heavy machinery.

- Automotive Systems – Used in vehicles to reduce road vibrations, enhancing comfort and performance.

- HVAC Systems – Applied to reduce vibrations in air conditioning and ventilation equipment.

- Precision Equipment – Helps maintain stability and accuracy by isolating unwanted vibrations in sensitive machinery.

Its versatility makes it ideal for systems where vibration control and stability are crucial.

How does the STRM Stabilizing Rubber Isolator work?

The STRM Stabilizing Rubber Isolator works by utilizing the inherent properties of rubber to absorb and isolate vibrations, providing stability and reducing the impact on machinery and systems. Here’s how it functions:

Vibration Absorption – The rubber material absorbs vibrations from the machinery or system, converting the kinetic energy from the vibrations into heat, which is dissipated. This reduces the transmission of vibration to surrounding components.

Elasticity and Flexibility – The isolator’s rubber construction allows for flexibility, enabling it to adjust to various load conditions while maintaining its damping properties.

Load Distribution – The isolator evenly distributes the weight and forces from the equipment, ensuring that vibrations are evenly absorbed and reducing stress on individual parts.

Noise Reduction – By minimizing vibrations, the isolator also helps reduce noise generated by machinery, creating a quieter working environment.

Overall, the STRM Stabilizing Rubber Isolator ensures that machinery operates smoothly with less vibration, extending the life of the equipment and improving system stability.

What are the product advantages of STRM Stabilizing Rubber Isolator?

The STRM Stabilizing Rubber Isolator offers several key advantages:

- Effective Vibration and Noise Reduction – It efficiently absorbs vibrations and reduces noise, creating a quieter and more stable operating environment.

- Improved Equipment Longevity – By reducing the wear and tear caused by vibrations, it helps extend the lifespan of machinery and equipment.

- Enhanced Stability – The isolator provides consistent performance, ensuring smooth and stable operation even under varying loads and conditions.

- Durable and Long-lasting – Made from high-quality rubber, it is designed to withstand long-term use and maintain its performance over time.

- Wide Application – Its versatile design makes it suitable for a wide range of applications, including industrial machinery, construction equipment, automotive systems, HVAC systems, and precision equipment.

- Cost-effective – By reducing maintenance costs and extending the lifespan of equipment, the isolator provides a cost-effective solution for vibration control.

These advantages make the STRM Stabilizing Rubber Isolator an ideal choice for improving the efficiency and longevity of equipment while maintaining optimal performance.

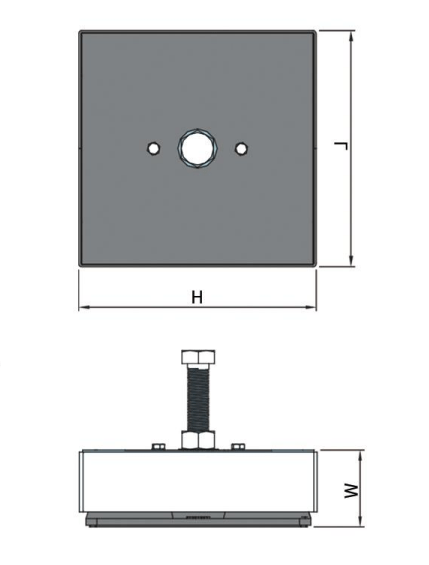

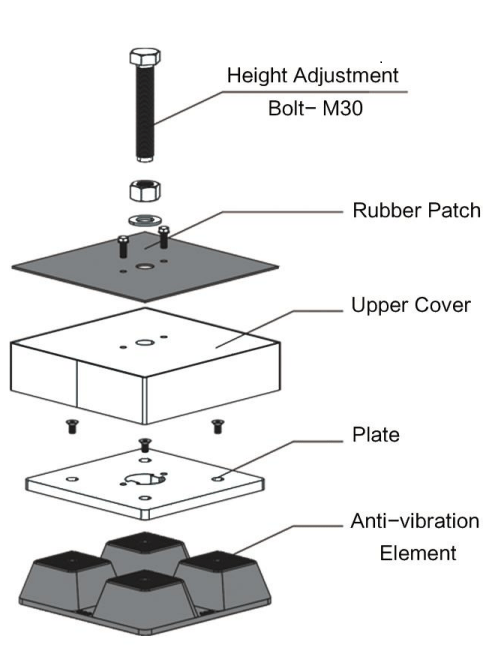

The STRM Stabilizing Rubber Isolator is designed with several key features to enhance its performance in vibration reduction and stability. Here are the main design aspects:

High-Quality Rubber Material – The isolator is made from durable and flexible rubber, which has excellent damping properties to absorb vibrations effectively and ensure long-lasting performance.

Optimized Shape and Structure – The design includes a carefully engineered shape that allows the isolator to distribute loads evenly, improving its ability to isolate vibrations across a wide range of operating conditions.

High Load Capacity – The isolator is designed to handle heavy loads while maintaining its vibration reduction capabilities, making it suitable for industrial machinery, automotive systems, and other heavy-duty applications.

Compact Design – The isolator is designed to be compact and space-efficient, allowing easy installation in confined spaces without compromising performance.

Adjustable Features – Some models of the isolator may include adjustable components, such as air pressure or load distribution settings, to allow for customization based on specific application requirements.

Durable Construction – The isolator is built to withstand harsh operating environments, including high temperatures, moisture, and other challenging conditions, ensuring consistent performance over time.

Simple Installation – The design allows for quick and easy installation, reducing downtime during setup and making it ideal for both new systems and retrofits.

These design elements ensure that the STRM Stabilizing Rubber Isolator performs effectively in reducing vibration, improving system stability, and extending the lifespan of the equipment it supports.

Here are the key precautions for installing and using the STRM Stabilizing Rubber Isolator:

Installation Precautions:

- Proper Positioning – Ensure the isolator is installed on a stable, level surface to prevent uneven load distribution and ensure effective vibration isolation.

- Check Compatibility – Make sure the isolator’s specifications (load capacity, size) are suitable for the equipment or system in use.

- Correct Alignment – Ensure proper alignment during installation to avoid unnecessary stress on the isolator and maintain optimal performance.

- Secure Mounting – The isolator should be firmly secured to prevent any movement during operation. Loose installation can affect vibration control and cause damage.

- Avoid Overloading – Do not exceed the isolator’s maximum load capacity, as overloading may lead to failure and reduced efficiency.

Usage Precautions:

- Regular Maintenance – Check the isolator regularly for any signs of wear, cracking, or damage. Ensure that the rubber is in good condition to maintain effective vibration isolation.

- Monitor Load and Pressure – For models with adjustable features, such as air pressure, ensure that the settings are adjusted according to the load and operational conditions.

- Avoid Harsh Conditions – Protect the isolator from extreme temperatures, excessive moisture, or harsh chemicals that could degrade the rubber and affect its performance.

- Proper Lubrication – If necessary, ensure proper lubrication for any moving parts to maintain smooth operation and avoid friction-related wear.

- Check Alignment During Operation – Monitor the isolator during operation to ensure it remains properly aligned and functioning as intended.

By following these precautions, the STRM Stabilizing Rubber Isolator will function optimally, extending the lifespan of the equipment and ensuring smooth, stable operations.

- STRM Stabilizing Rubber Isolator are typically available in stock.

- STRM Stabilizing Rubber Isolator manufactured by Shanghai Songjiang meet national standards and come with a one-year warranty. Any quality issues can be exchanged within this period.

- There is no purchase quantity limit. Small orders are generally shipped via international couriers such as DHL, FEDEX, UPS, TNT, etc., ensuring fast delivery, usually within 3-7 business days.