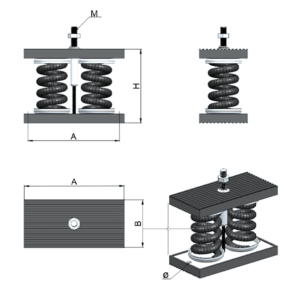

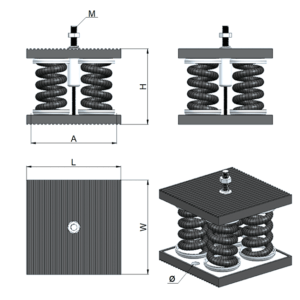

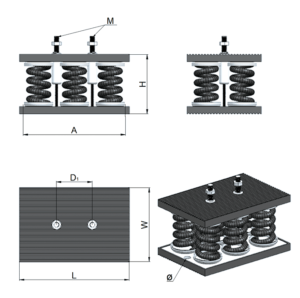

JS Type Spring Vibration Mount

JS Type Spring Vibration Mount

Frequently Asked Questions

What systems are JS Type Spring Vibration Mounts used in?

JS Type Spring Vibration Mounts are widely used in various applications to provide effective vibration isolation and noise reduction. Here are some extended uses:

HVAC Systems: These mounts are used to isolate vibrations from air handling units, compressors, chillers, and cooling towers. They help improve comfort and prevent structural damage due to excessive vibrations.

Industrial Machinery: Ideal for heavy-duty machinery like pumps, compressors, motors, turbines, and generators, the mounts help reduce mechanical noise and vibration that could cause wear and tear on equipment and nearby structures.

Transport Systems: In railways, automotive, and aerospace, these mounts are used to reduce vibrations in engines, vehicle suspensions, and other critical components, enhancing performance and rider comfort.

Building and Construction: Used in the isolation of vibration from mechanical systems in buildings such as elevators, escalators, or industrial equipment in factories. They also reduce the transmission of noise and vibrations to neighboring structures.

Electrical and Power Equipment: In power plants or substations, where transformers, turbines, and other equipment may generate significant vibrations, JS Type mounts ensure a quieter environment and extend the life of electrical systems.

Offshore and Marine: They are effective for use in marine and offshore platforms, where vibration control is critical in maintaining the stability and safety of sensitive equipment like drilling rigs and turbines.

Renewable Energy: In wind turbine installations and other renewable energy systems, these mounts are used to reduce the vibrations from moving parts, improving efficiency and reducing maintenance needs.

These mounts are designed to work effectively across a wide range of environments, offering flexible, long-lasting solutions for vibration isolation and noise reduction in diverse applications.

How does the JS Type Spring Vibration Mount work?

JS Type Spring Vibration Mount works by using the principle of spring-based vibration isolation. Here’s how it functions:

Vibration Absorption: The mount is designed with springs that absorb and dampen vibrations from equipment or machinery. As the equipment operates, vibrations are transferred to the mount, where the springs compress and expand to absorb the energy, reducing the transmission of vibrations to the surrounding structure.

Load Support: The springs within the mount also support the weight of the equipment. They are carefully calibrated to maintain the equipment’s stability while isolating vibrations. The amount of compression or expansion of the springs adjusts according to the load, ensuring effective isolation and maintaining system balance.

Noise Reduction: By isolating vibrations, the JS Type Spring Vibration Mount helps reduce noise generated from mechanical systems. This is especially beneficial in environments where excessive noise from HVAC units, industrial machinery, or transportation systems can be disruptive.

Durability and Performance: The mount is built to withstand harsh working conditions and maintain performance over time. Its materials are chosen to resist wear, corrosion, and damage, ensuring long-term effectiveness in vibration isolation.

In short, the JS Type Spring Vibration Mount functions by absorbing vibrations through its spring system, supporting the equipment load, and reducing noise, resulting in a quieter, more stable operational environment.

What are the product advantages of JS Type Spring Vibration Mounts?

Advantages of JS Type Spring Vibration Mounts:

Effective Vibration Isolation:

- JS Type Spring Vibration Mounts effectively absorb and isolate vibrations from equipment, reducing the impact of vibrations on the surrounding environment, especially in industrial and HVAC systems.

Noise Reduction:

- By reducing vibrations, JS Type Spring Vibration Mounts significantly decrease the noise generated during equipment operation, enhancing the comfort of the work environment and meeting modern environmental standards.

Increased Equipment Lifespan:

- By absorbing vibrations and shocks, the mounts help reduce wear and tear on machinery, extending the equipment’s service life and lowering maintenance costs.

High Load Capacity:

- JS Type Spring Vibration Mounts have a high load-bearing capacity, making them suitable for heavy-duty machinery and equipment, capable of withstanding significant pressure and impacts.

Durability:

- Made from wear-resistant and corrosion-resistant materials, JS Type Spring Vibration Mounts remain stable and reliable even in harsh environments.

Wide Applicability:

- Suitable for various industries and applications, including HVAC systems, industrial machinery, and transportation, offering strong versatility and flexibility.

The JS Type Spring Vibration Mount is designed with specific features to provide effective vibration isolation and noise reduction. Here are the key design elements:

Spring-based Isolation:

- The core of the JS Type is its spring mechanism, which absorbs vibrations and isolates the equipment from the surface it is mounted on. This helps in reducing both structure-borne noise and mechanical vibrations.

Heavy-duty Construction:

- Designed for heavy-duty applications, the mount can handle high loads and shock absorptions. It uses high-strength steel or other durable materials for the spring and other components to ensure long-lasting performance under tough conditions.

Adjustable Features:

- Some models of the JS Type Spring Vibration Mount come with adjustable spring tension, allowing the user to fine-tune the level of vibration isolation depending on the load and operational requirements.

Corrosion-resistant Coating:

- The components are often coated with corrosion-resistant materials, such as galvanized steel, to protect them from environmental factors like moisture and chemicals, ensuring durability in various environments.

Versatile Mounting Options:

- JS Type Spring Vibration Mounts come with different mounting configurations (e.g., threaded, flange, or base plate) to provide flexibility for installation in various systems and machinery.

Multi-layer Design:

- Some models feature a multi-layer spring design to provide different levels of vibration damping, catering to specific needs like heavy-duty equipment or sensitive machinery.

Compact and Efficient:

- Despite their heavy-duty performance, these mounts are designed to be compact and space-efficient, fitting into various machinery designs without taking up excessive space.

Noise Reduction:

- The design minimizes noise transmission by decoupling the equipment from the structure, resulting in a quieter environment, especially in HVAC systems and industrial machinery.

These features make the JS Type Spring Vibration Mount an effective solution for vibration isolation, supporting a wide range of industries from HVAC to industrial machinery.

Precautions for Installing and Using JS Type Spring Vibration Mount:

Correct Alignment:

- Ensure proper alignment between the vibration mount and the equipment, as well as the foundation. Misalignment may reduce the effectiveness of vibration isolation and lead to uneven load distribution.

Check Load Capacity:

- Before installation, verify that the load capacity of the JS Type Spring Vibration Mount is suitable for the equipment’s weight and operational conditions. Overloading can cause the mount to fail or wear out prematurely.

Level Surface for Installation:

- Install the vibration mounts on a flat, clean surface free of dirt and debris. An uneven or contaminated surface can affect the mount’s performance and stability.

Tighten Fasteners Properly:

- Ensure that all bolts, screws, and connections are tightly secured. Loose fasteners may lead to mount instability, decreased vibration isolation performance, or equipment damage.

Adjust Spring Tension (if applicable):

- If the mount is adjustable, ensure the spring tension is set correctly based on the equipment’s load and vibration characteristics. Improper adjustment can lead to inadequate vibration isolation or mechanical failure.

Avoid Over-compression:

- Do not over-compress the springs during installation. Over-compression may hinder the mount’s ability to function properly, leading to reduced vibration damping and potential damage to the spring.

Environmental Considerations:

- Install the vibration mount in an environment that is within its specified operating temperature range. Extreme conditions such as high temperatures or corrosive environments can affect the performance and durability of the mount.

Regular Maintenance:

- Periodically inspect the vibration mounts for signs of wear, corrosion, or damage. Perform necessary maintenance such as cleaning, lubrication (if required), and re-adjustment to ensure the mount is functioning optimally.

Protection from External Damage:

- Protect the vibration mount from any external physical damage during installation or operation. If necessary, use protective covers or shields to prevent damage from external impacts.

By following these precautions, you can ensure that the JS Type Spring Vibration Mount functions effectively, extends the lifespan of your equipment, and provides efficient vibration isolation.

- JS Type Spring Vibration Mounts are typically available in stock.

- JS Type Spring Vibration Mounts manufactured by Shanghai Songjiang meet national standards and come with a one-year warranty. Any quality issues can be exchanged within this period.

- There is no purchase quantity limit. Small orders are generally shipped via international couriers such as DHL, FEDEX, UPS, TNT, etc., ensuring fast delivery, usually within 3-7 business days.

JS Type Spring Vibration Mount Model List :